High-temperature-resistant solar power generation panel device with novel structure

A technology of solar power generation panels and high temperature resistance, which is applied in the direction of solar thermal power generation, photovoltaic power generation, and the support structure of photovoltaic modules, etc. It can solve the problems of lack of sealed heat dissipation function, lack of automatic conveying structure, inconvenient heat dissipation protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

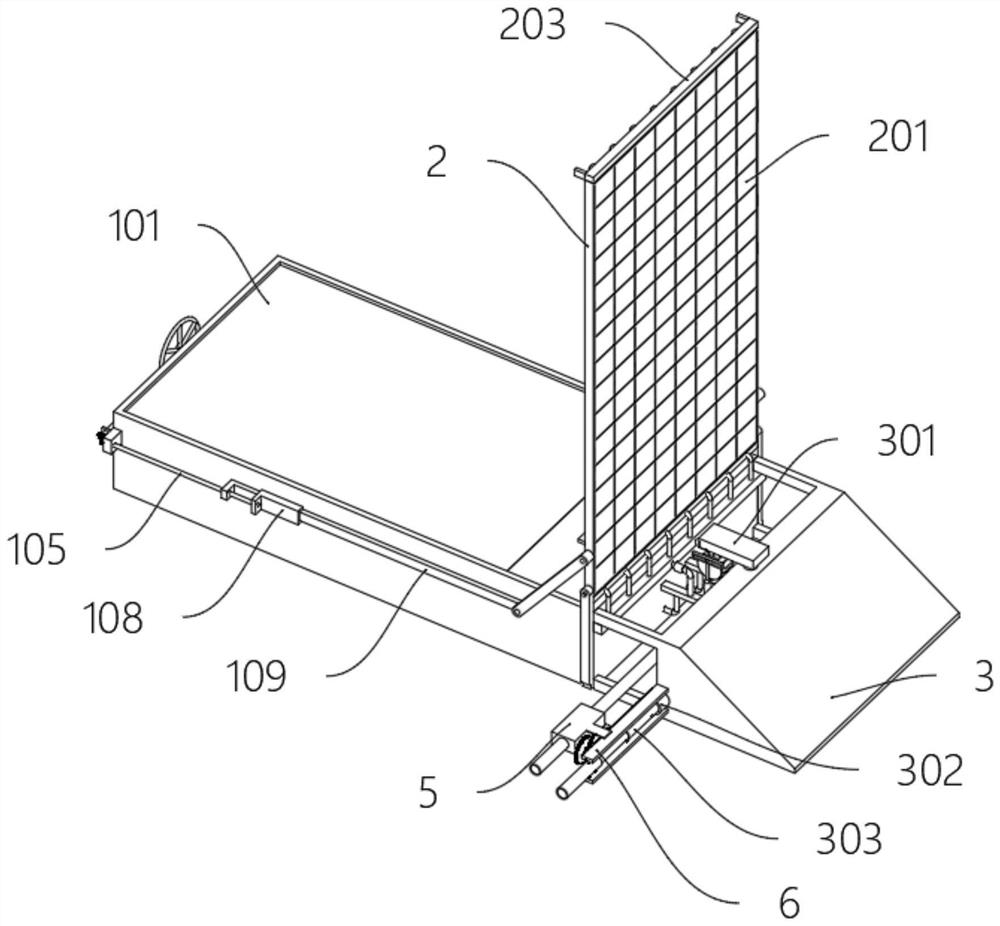

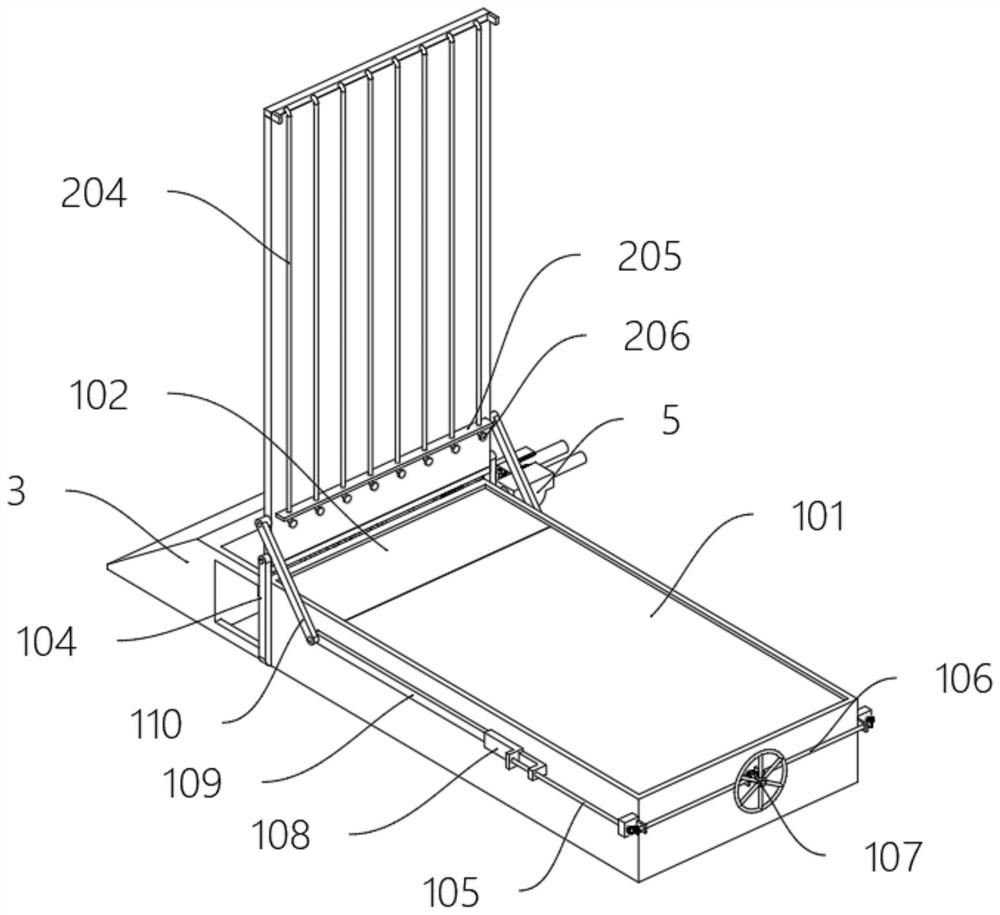

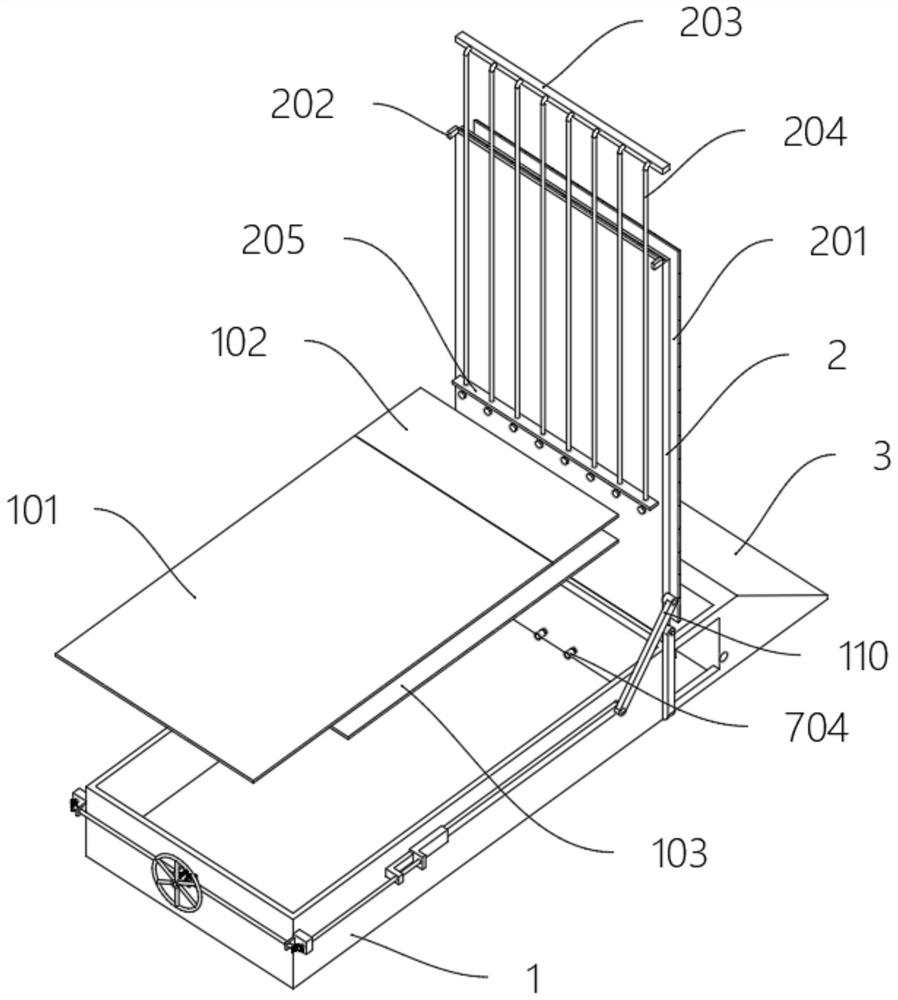

[0031] Example: please refer to Figure 1 to Figure 8 :

[0032] The present invention proposes a high temperature resistant solar power generation panel device with a new structure, comprising: a receiving box 1, a first-level baffle 101 and a filter cotton pad 102 are fixedly arranged on the inner top of the receiving box 1, and a second-level baffle is fixedly arranged on the inner side of the receiving box 1 103, the front side of the secondary baffle 103 does not contact the inner wall of the receiving box 1; the front ends of the two sides of the receiving box 1 are fixedly arranged with two sets of fixed columns 104; the photovoltaic seat 2, the photovoltaic seat 2 is hingedly arranged on the top of the fixed column 104; The heating box 3, the main body of the heating box 3 is a wedge-shaped structure, the heating box 3 is fixedly arranged on the front side of the receiving box 1 with the bracket; the top of the heating box 3 is fixedly provided with a connecting channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com