Online measurement device for fineness of boiler coal powder on basis of image processing

A pulverized coal fineness and image processing technology, applied in the direction of measuring devices, particle size analysis, instruments, etc., can solve the problems of not meeting the real-time adjustment needs of boilers, high maintenance costs, long measurement cycles, etc., and achieve the effect of real-time online measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings. Those skilled in the art should understand that the embodiments described below are only illustrative illustrations of the present invention, and are not intended to limit it in any way.

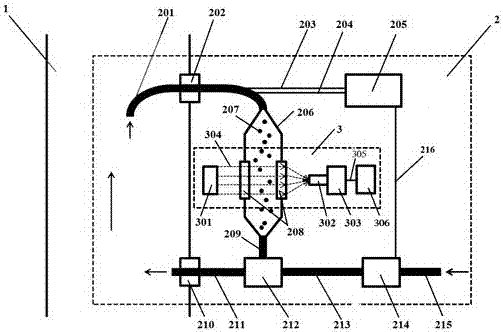

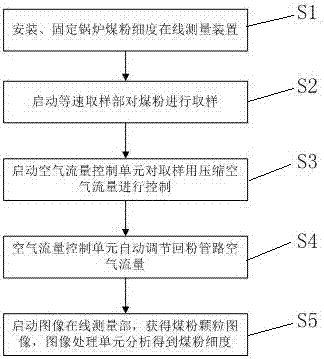

[0025] like figure 1 As shown, the present invention provides an online measuring device for fineness of boiler coal based on image processing, and the preferred embodiment includes: a constant velocity sampling part 2 for boiler pulverized coal, which is used for circulating constant velocity sampling of pulverized coal in the pulverized coal pipe; image online The measuring part 3 is used to obtain the sampled pulverized coal image and analyze it to obtain fineness parameters.

[0026] The boiler pulverized coal constant velocity sampling unit 2 is installed on the pulverized coal pipe 1 as follows: the curved sampling pipe 201 is installed on the pulverized coal pipe 1 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com