Anti-shaking device used during cargo butt joint

A technology for anti-shake and cargo, which is applied in the direction of lifting devices, storage devices, electric vehicles, etc., and can solve the problems of cargo scattering, position deviation, shaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

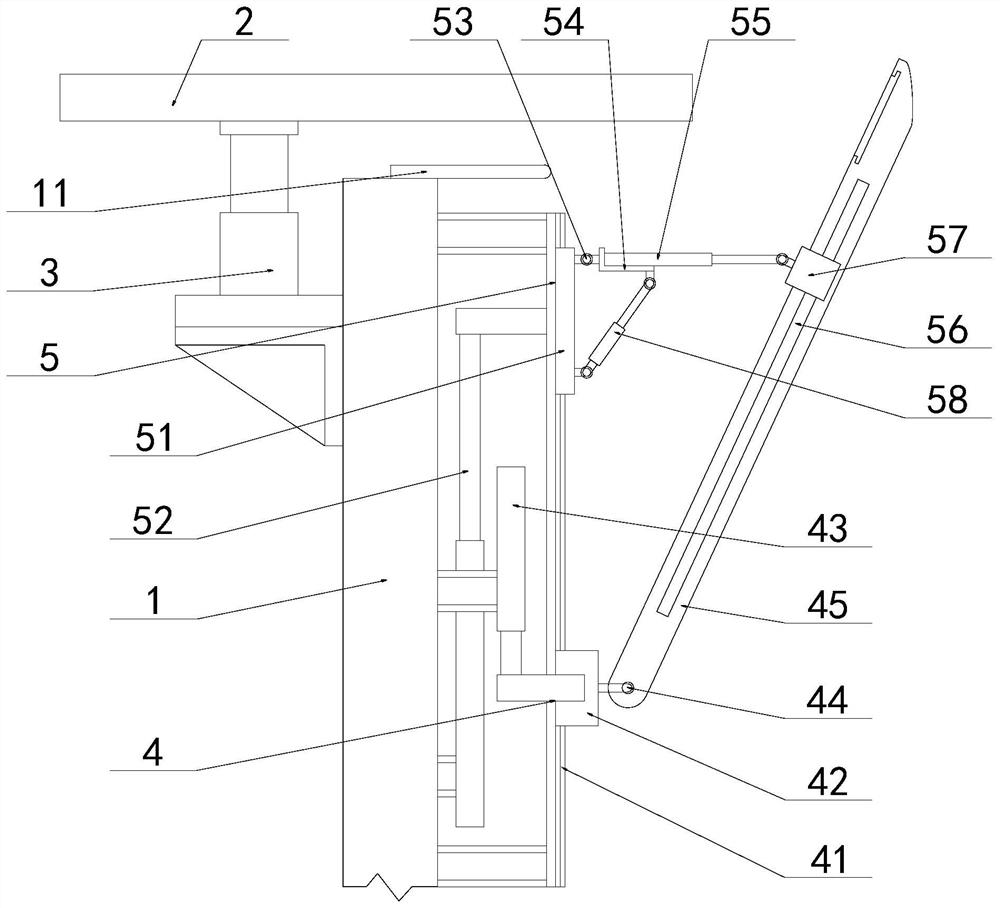

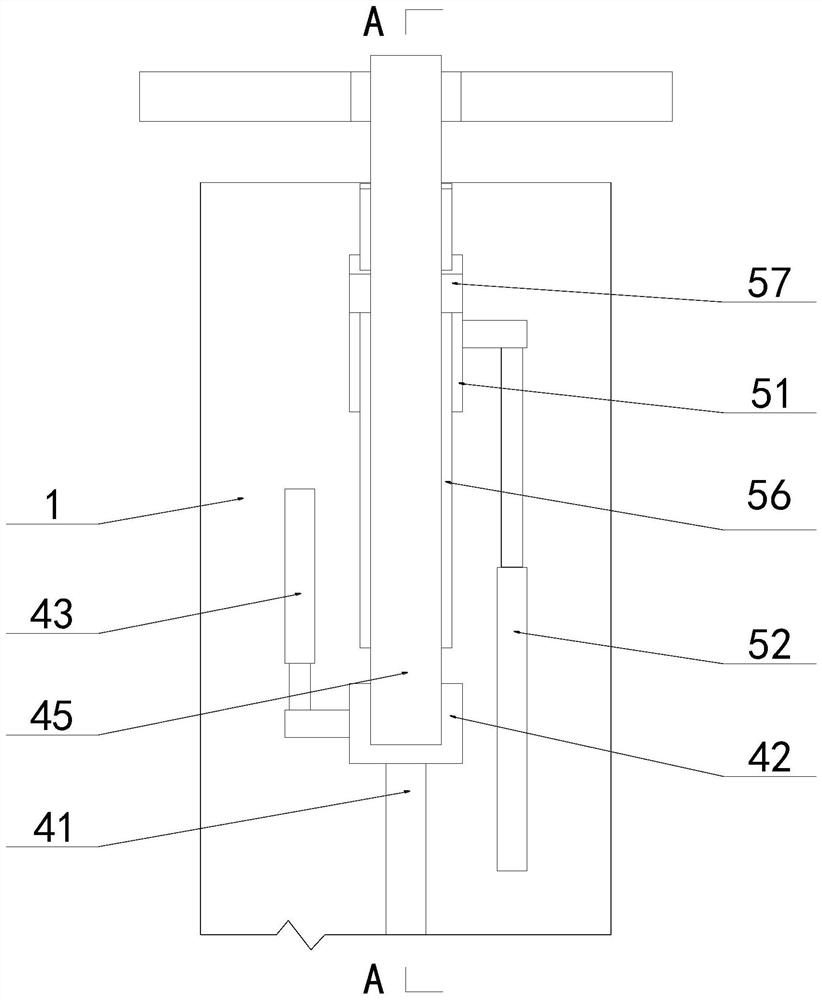

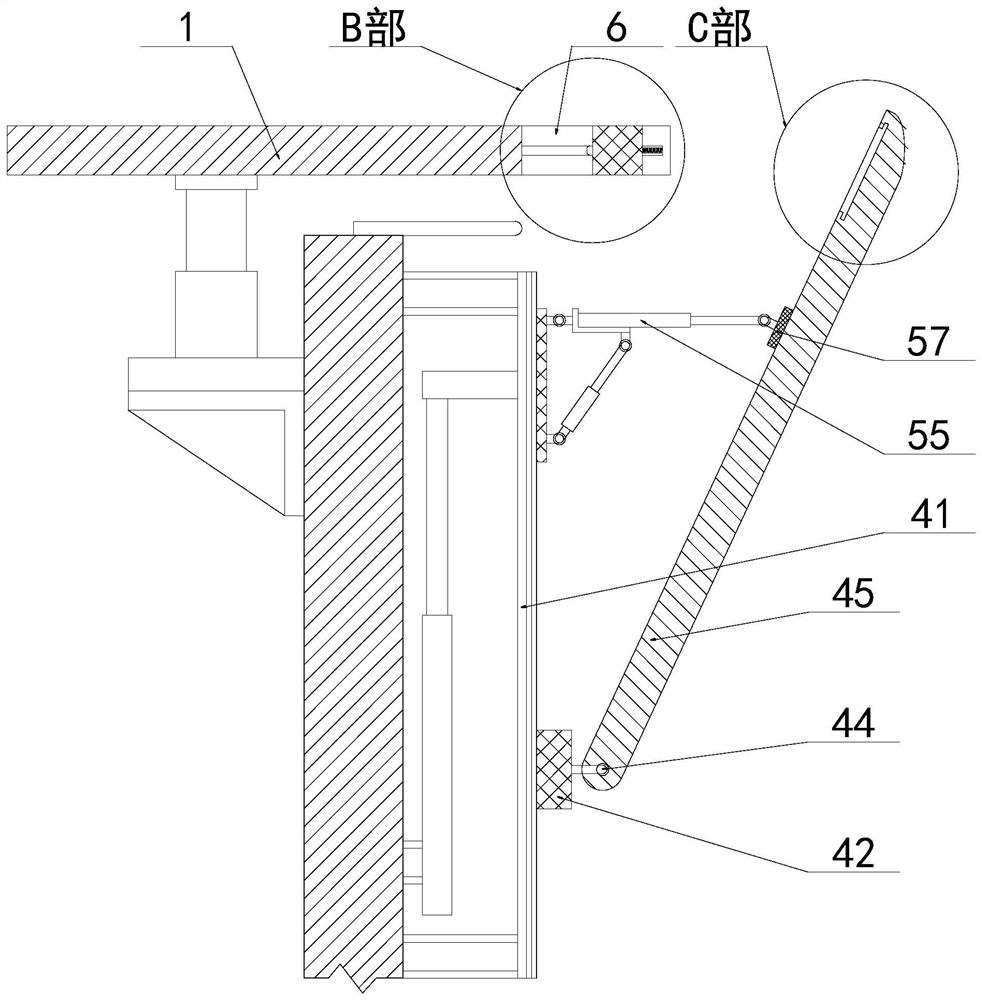

[0042] Please refer to Figure 1-Figure 5 ,in, figure 1 is the structural schematic diagram of the present invention; figure 2 Yes figure 1 the right view; image 3 Yes figure 2 A-A sectional view in ; Figure 4 Yes image 3 Enlarged view of part B in ; Figure 5 Yes image 3 Enlarged view of section C in .

[0043] The embodiment of the present application provides an anti-shake device when goods are docked, including a frame 1, a support platform 2 and a hydraulic lifting device 3, wherein the hydraulic lifting device 3 is fixedly arranged on the frame 1, and the bearing platform 2 is fixedly arranged on the hydraulic lifting device 3. On the output end of the lifting device 3, the anti-shake device further includes:

[0044] Drive assembly 5, the drive assembly 5 is arranged on the frame 1, and the output end of the drive assembly 5 is interconnected with the support assembly 4;

[0045] Support assembly 4, the support assembly 4 is arranged on the frame 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com