Full-automatic substrate cleaning machine

A cleaning machine, fully automatic technology, applied in the direction of steam flow control, electrostatic effect separation, solid separation, etc., can solve the problem of removing dust and debris on the surface of the substrate, unable to accurately reflect the production status of the product, and increase the number of artificial collision products. and other problems to achieve the effect of thorough cleaning and dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

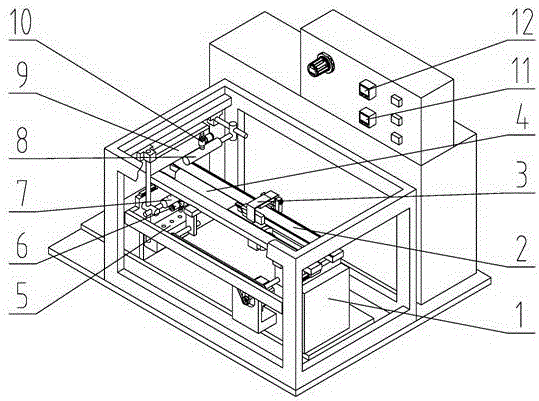

[0019] Attached below figure 1 The present invention is described in further detail with the specific embodiment:

[0020] Depend on figure 1 It can be seen that the present invention includes: base 1, front and rear guide rails 2, pneumatic gripper 3, base plate 4, lower electrostatic wind bar 5, lower blowing nozzle pressure regulating valve 6, lower blowing nozzle 7, upper blowing nozzle 8, upper electrostatic Wind rod 9, upper air blowing nozzle pressure regulating valve 10, air blowing low pressure stop pressure switch 11, air blowing recovery pressure switch 12.

[0021] Working process of the present invention is as follows:

[0022] 1. The pneumatic gripper 3 moves left along the front and rear guide rails 2 and closes, grabs the substrate 4 and moves right to the set position, the lower electrostatic air bar 5, the lower air blowing nozzle 7, the upper air blowing nozzle 8, and the upper electrostatic air bar 9 Open at the same time, blowing air to clean and remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com