Easy-to-control coater

A coating machine and coating technology, which is applied to the device for coating liquid on the surface, coating, pretreatment surface, etc., can solve the problems of difficult control of stability, low production efficiency, unreasonable structural design, etc. The power is stable and easy to control, the cleaning and dust removal are uniform, and the structure design is reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

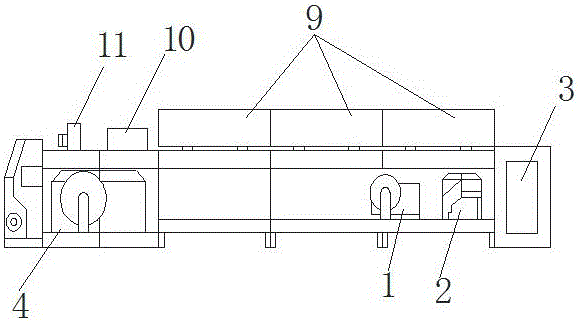

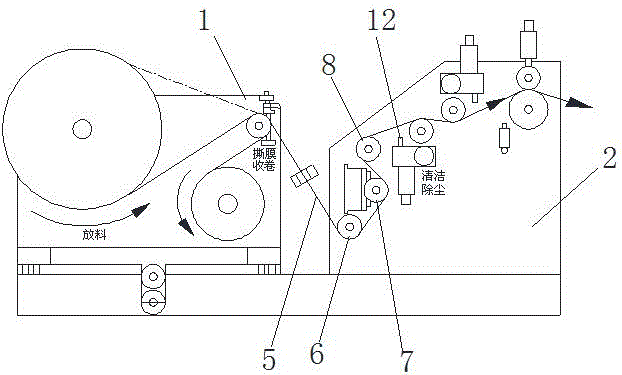

[0016] As attached to the manual figure 1 and 2 As shown, an easy-to-control coating machine includes a discharge mechanism 1, a cleaning and dust removal mechanism 2, a coating mechanism 3, a baking mechanism and a receiving mechanism 4; 5 three guide rollers 6, 7, 8 arranged in sequence, wherein, the first guide roller 6 is located above the substrate transmission line 5, the second guide roller 7 is located on the left side of the substrate transmission line 5, and the third guide roller 8 is located The right side of the base material transmission line 5; the discharge mechanism 1 is connected to the interior of the cleaning and dust removal mechanism 2 through the base material transmission line 5; inside the cleaning and dust removal mechanism 2, the base material transmission line 5 is first connected to three guide rollers 6 arranged in sequence, 7,8, and then transported to the starting point 12 for cleaning and dust removal; its baking mechanism includes three ovens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com