Automatic dust collector for air filter of engine

A filter and deceleration motor technology, applied in the direction of fuel air filter, etc., can solve the problems of incomplete and incomplete cleaning of filters, waste of financial resources, and substandard exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

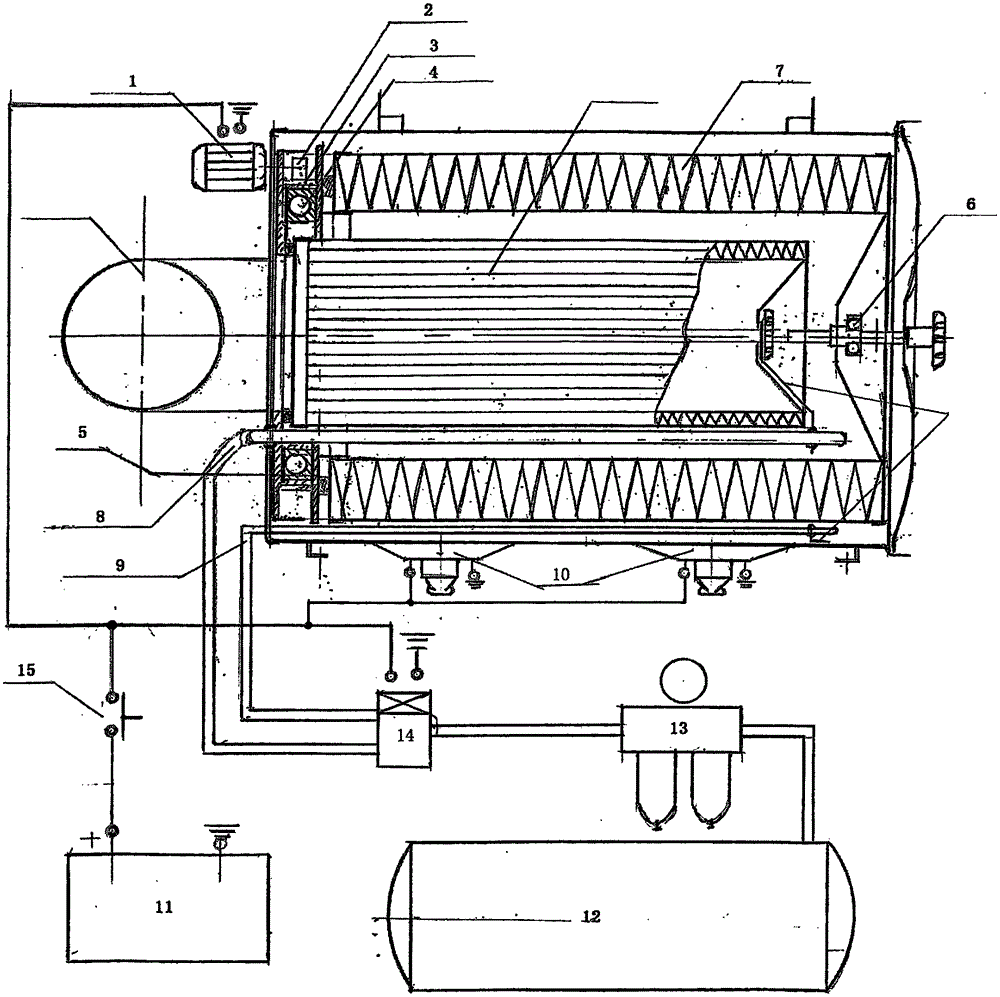

[0007] 1. When the engine is at rest (stop working), press the dust collector switch 15, and the motor will turn

[0008] Moving 1 drives the pinion 2, the ring gear 3, the main bearing 4, the pressure plate assembly 5, the rotating bearing bracket 6, and drives the main filter 7 to rotate.

[0009] 2. The high-pressure gas in the gas storage tank 12 flows through the water removal cup 13 to remove water, passes through the electromagnetic valve to divert the flow 14, and enters the dust removal pipe 8 and the dust discharge pipe 9 for dust removal operation.

[0010] 3. The axial-flow induced draft fan uses high-speed induced air to remove dust, and the dust is discharged out of the filter assembly housing, and the dust removal is completed once.

[0011] 4. It takes 5-8 seconds for the main filter to rotate for one revolution, and the high-pressure gas in the gas storage tank is sufficient for secondary dust removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com