Patents

Literature

45results about How to "Easy to clean dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

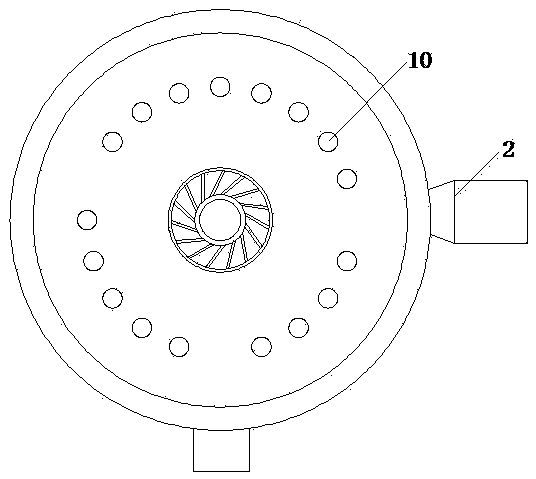

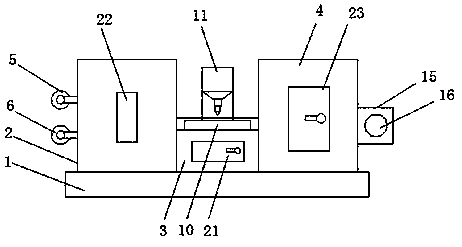

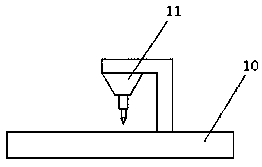

Industrial waste crushing device capable of purifying dust

InactiveCN108421615AEasy to clean dustEasy dischargeUsing liquid separation agentGrain treatmentsHydraulic cylinderGear wheel

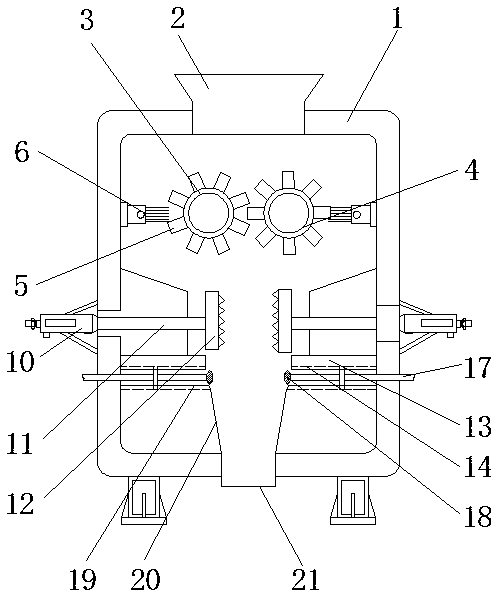

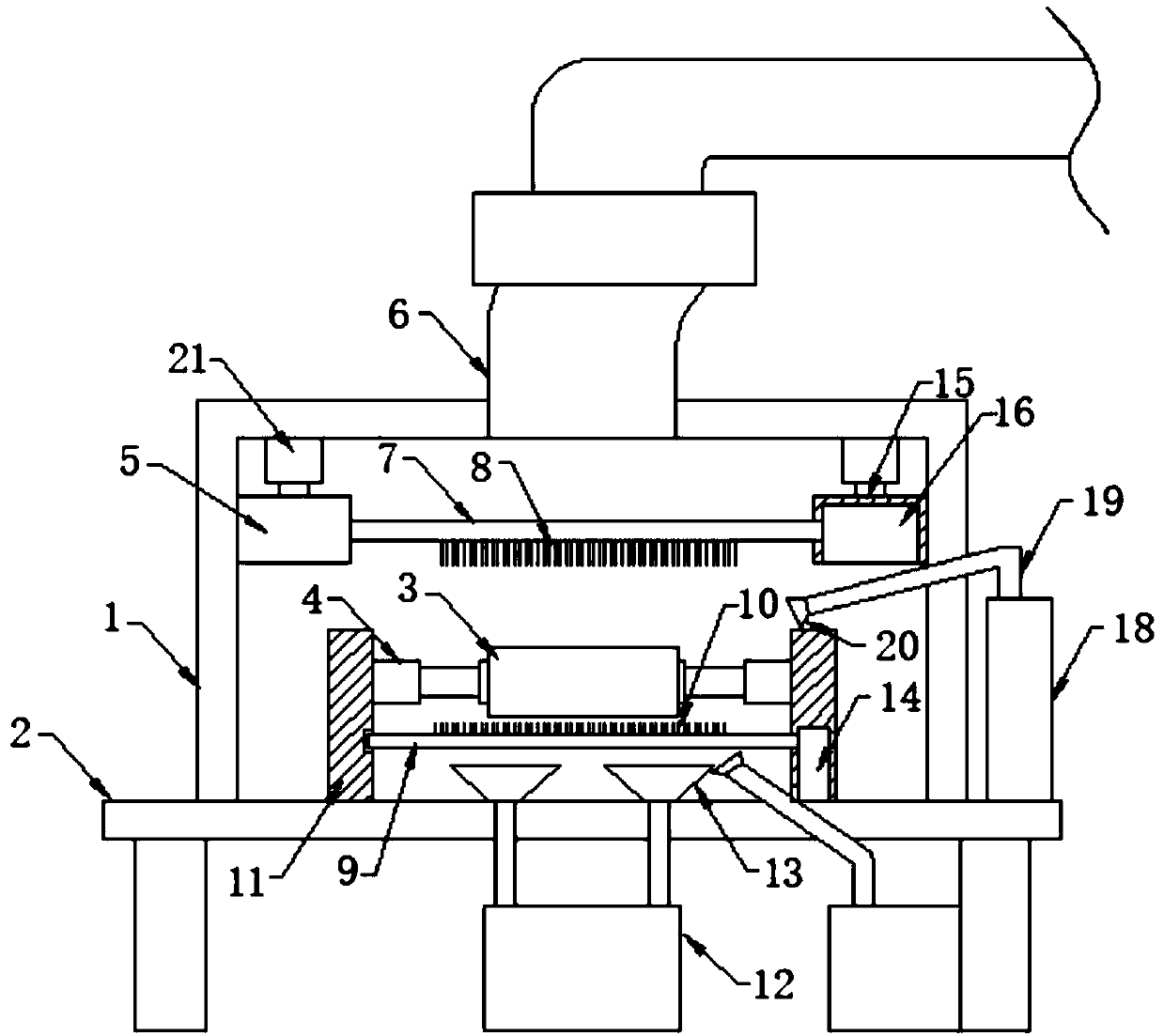

The invention discloses an industrial waste crushing device capable of purifying dust. The industrial waste crushing device comprises a box body, a connecting rod and a guide plate, wherein a feedinghole is fixed on the top of the box body; a first rotating shaft is arranged inside the box body; a second rotating shaft is arranged on the right side of the first rotating shaft; crushing blades arefixed on outer walls of the second rotating shaft and the first rotating shaft; hairbrushes are arranged on the left side of the first rotating shaft and the right side of the second rotating shaft;a driving gear is fixedly arranged on the right side of the first rotating shaft; the connecting rod penetrates through the box body and is connected with a hydraulic cylinder; a pressing plate is arranged on the right side of the connecting rod; a mounting plate is arranged below a lantern ring; the left side of the guide plate is connected with the mounting plate; a discharging hole is formed inthe bottom of the guide plate. The industrial waste crushing device capable of purifying dust is provided with a water pipe, and the water pipe is positioned below the pressing plate, so that the crushed wastes can be conveniently subjected to dust purification, and a phenomenon that the dust and wastes are discharged together is reduced.

Owner:ZHANGZHOU LONGWEN WEIKE INFORMATION TECH CO LTD

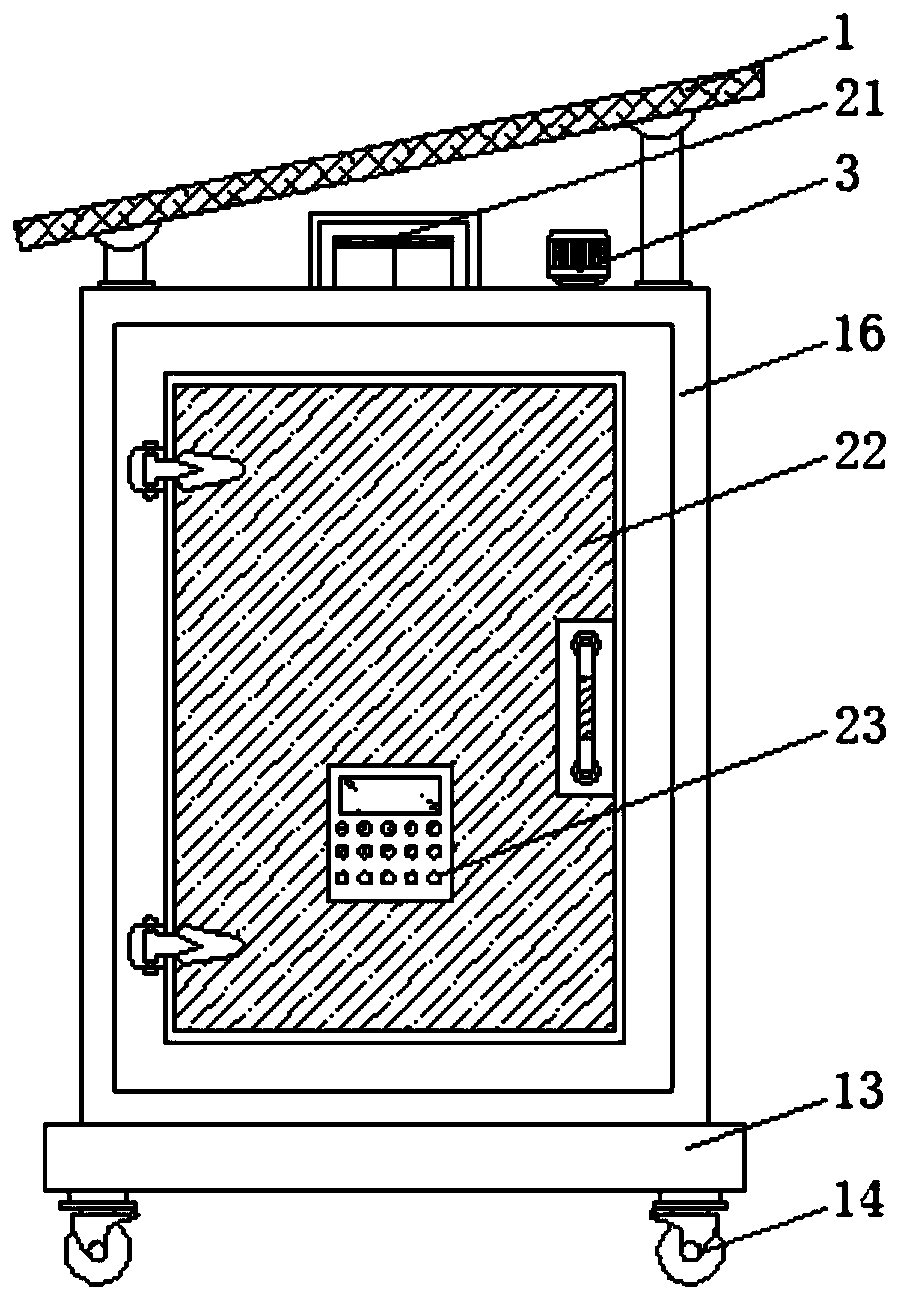

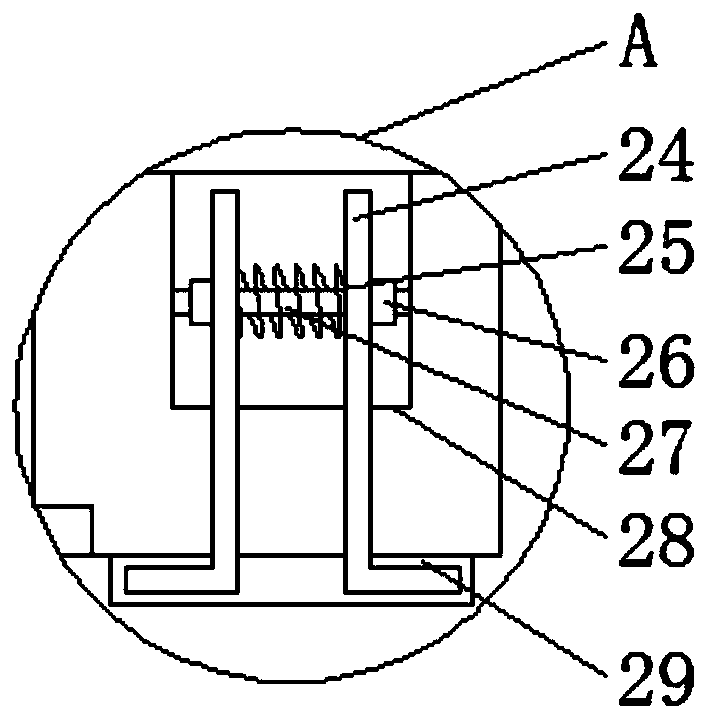

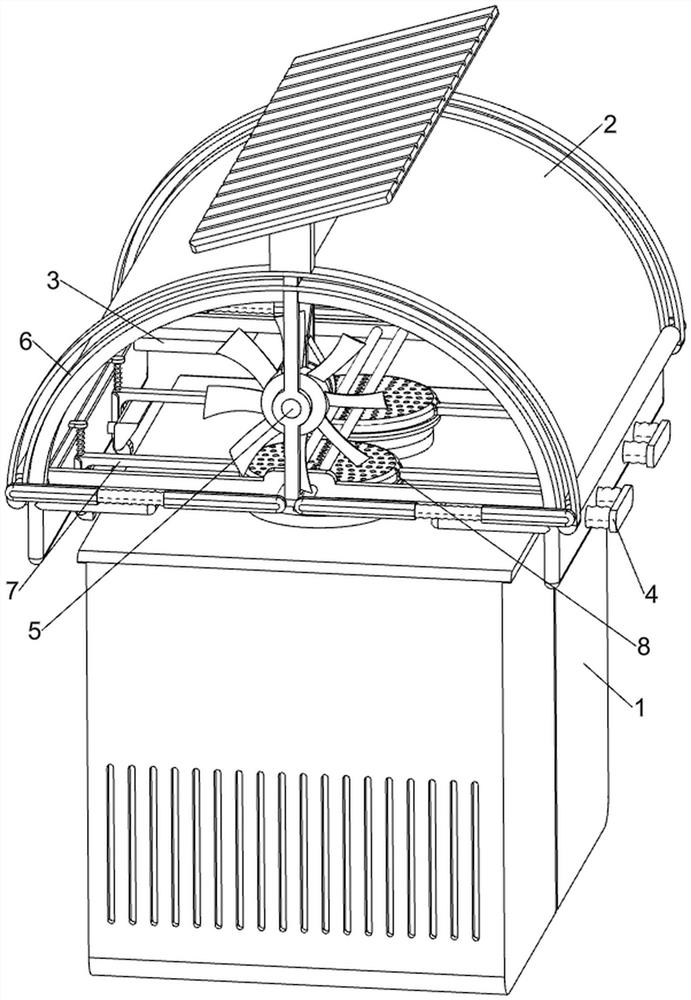

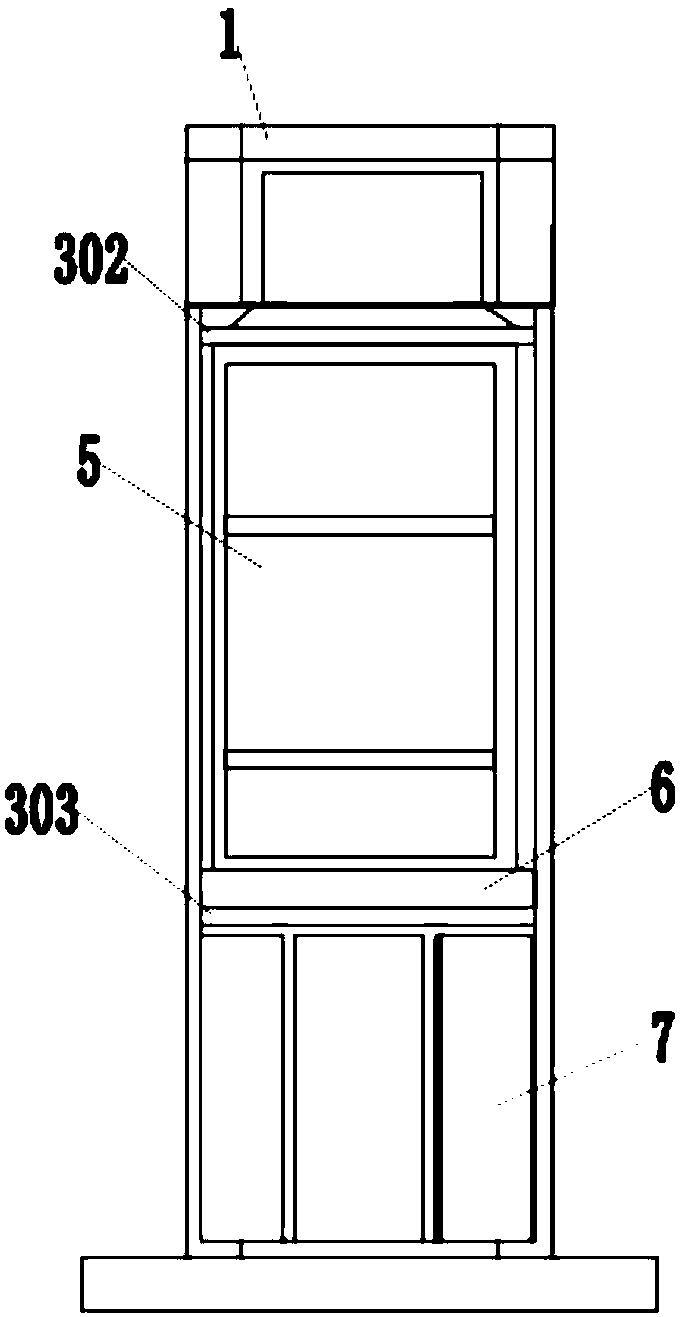

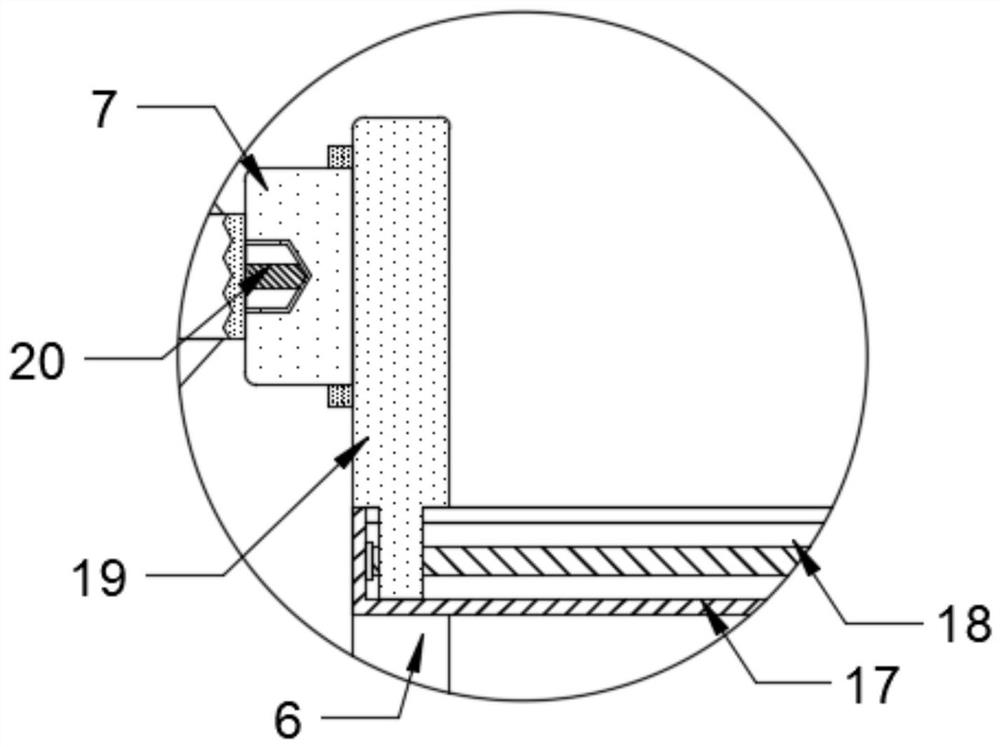

Switch cabinet with dust removal device

PendingCN111541177AEasy to clean dustEasy to remove dustBatteries circuit arrangementsSubstation/switching arrangement cooling/ventilationDust controlStructural engineering

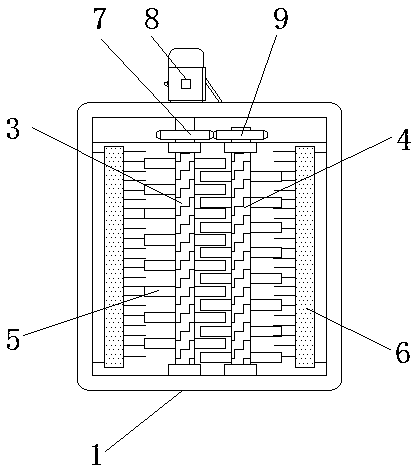

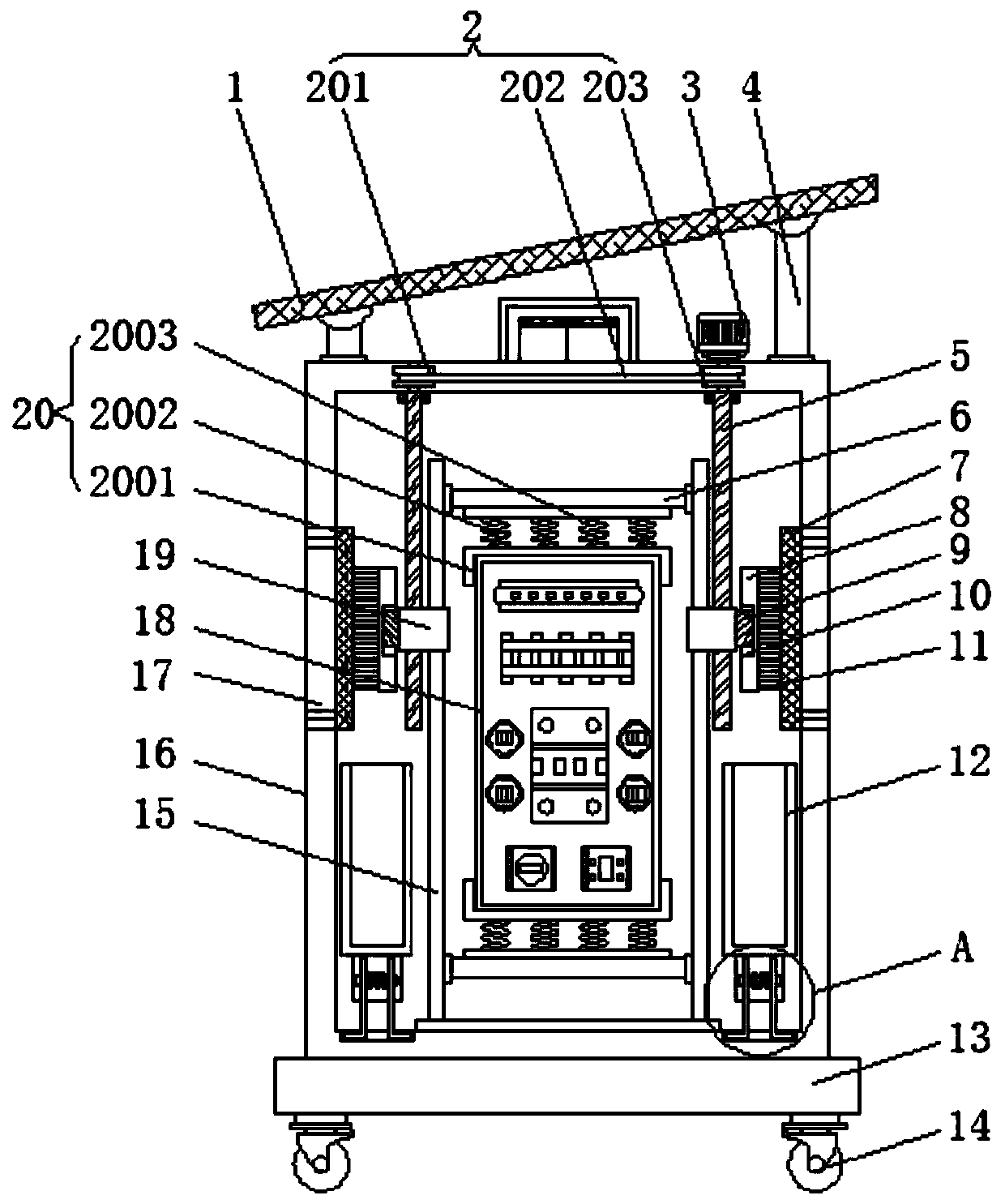

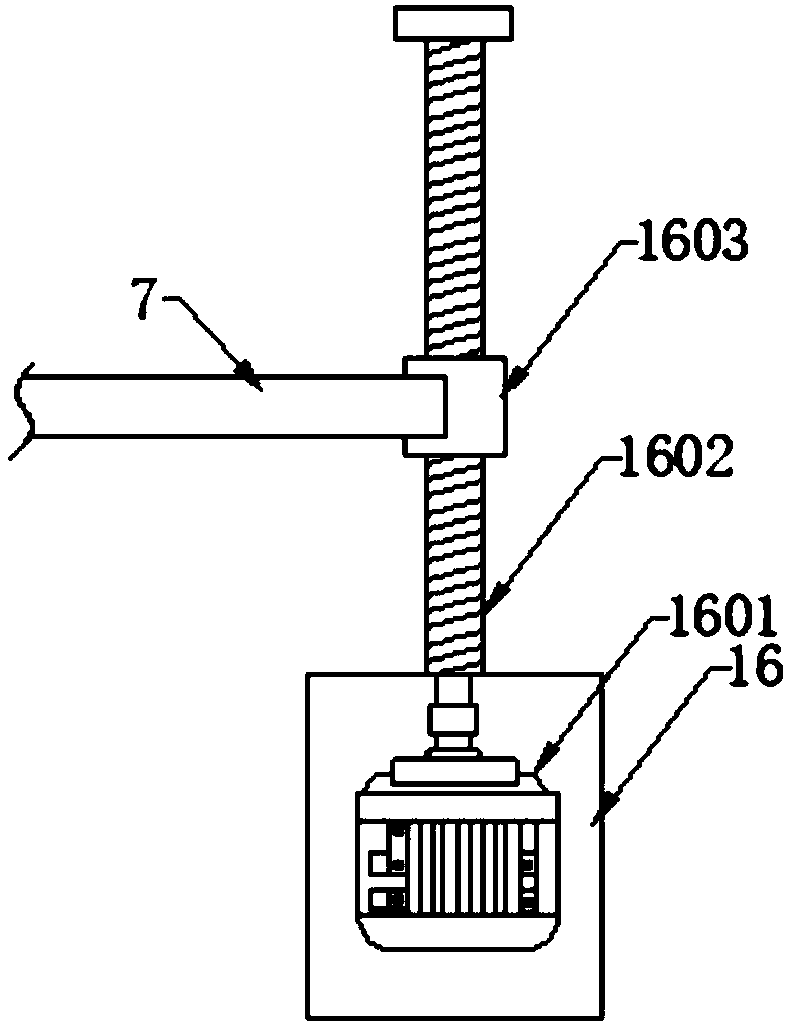

The invention discloses a switch cabinet with a dust removal device. The switch cabinet includes a base, rollers are mounted at four corners of the bottom of the base; a cabinet body is fixed to the top of the base, a door body is installed on the front face of the cabinet body through a hinge shaft, a control panel is mounted below the front surface of the door body; supporting columns are vertically welded to the left end and the right end of the top of the cabinet body, a solar cell panel is transversely mounted at the tops of the supporting columns; and a storage battery is mounted at thetop of the cabinet body below the solar cell panel. According to the invention, dust falls on a filter plate through a heat dissipation port; the control panel controls a servo motor to rotate; the servo motor drives a screw rod to rotate through a driving mechanism; the screw rod rotates to drive a driving block to slide, and the driving block slides to drive a cleaning plate to move, so that a brush is conveniently used for cleaning and dedusting the filter plate, the cleaned dust falls into the inner cavity of a dust collection frame to be uniformly collected, the switch cabinet is conveniently dedusted, and the phenomenon of short circuit of internal electrical components caused by dust accumulation is avoided.

Owner:江苏烨明光电有限公司

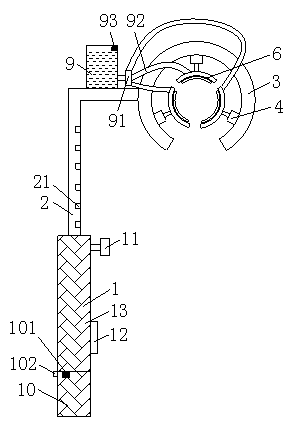

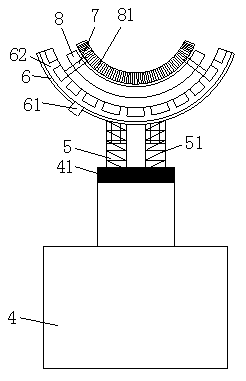

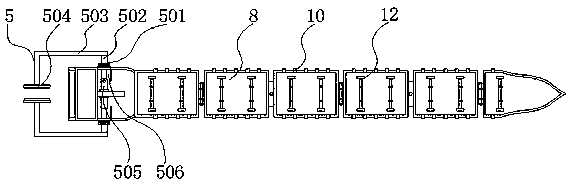

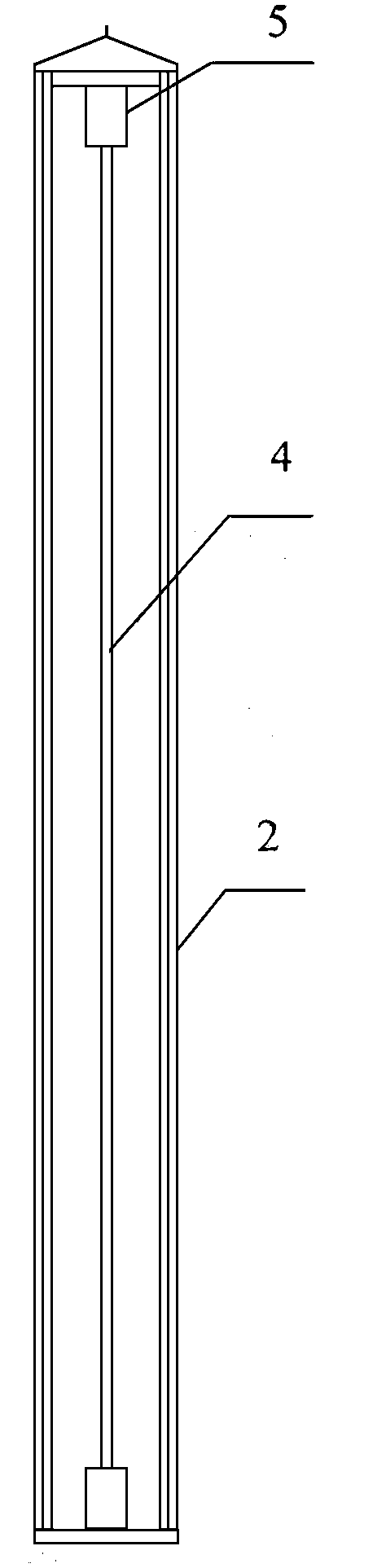

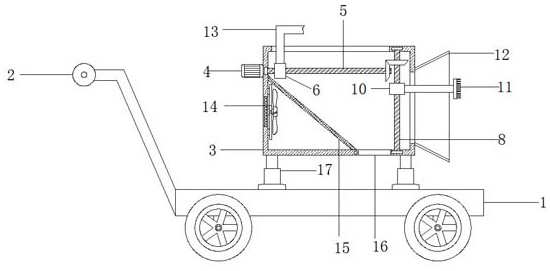

Electrically adjustable electric cleaner

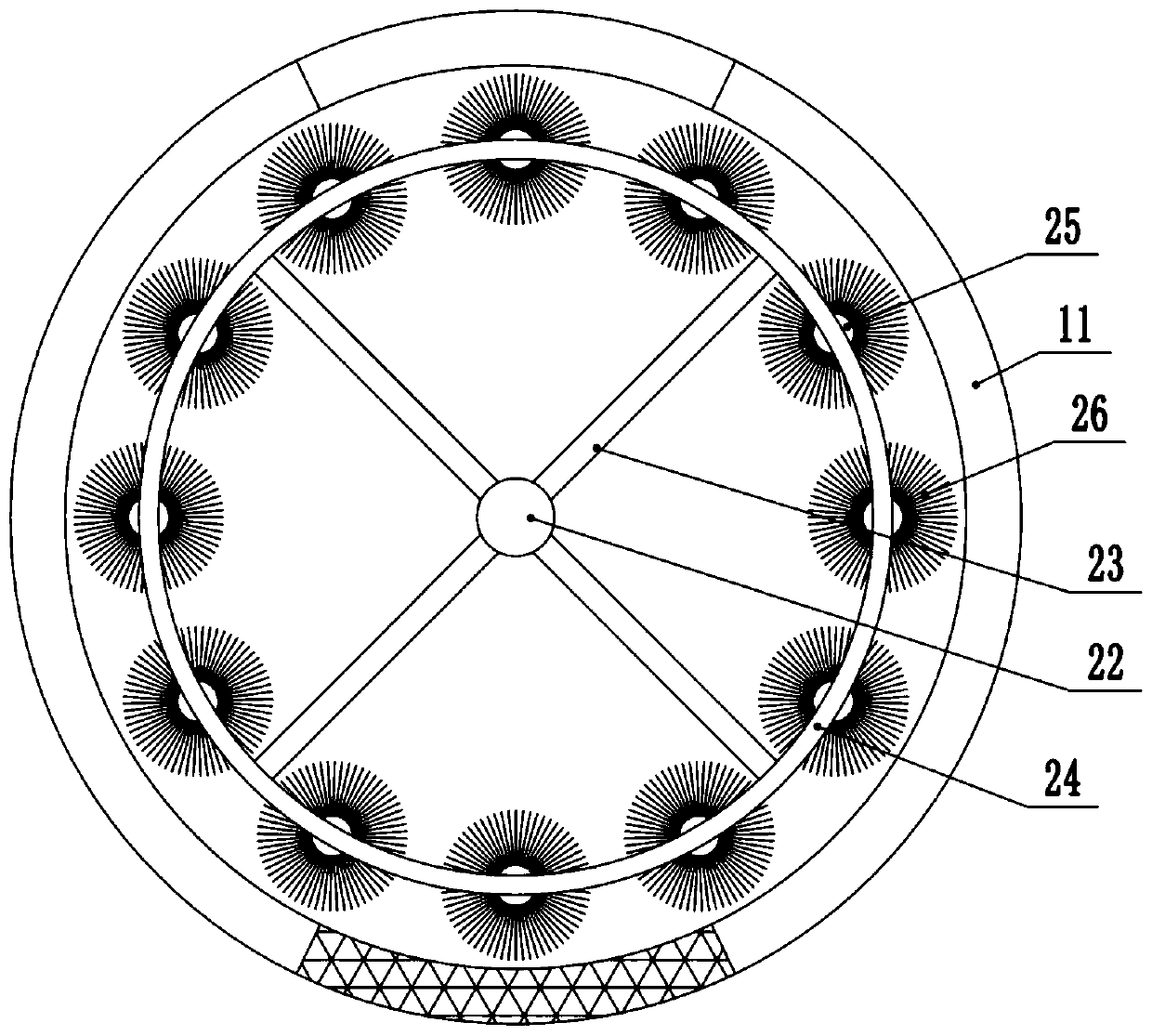

ActiveCN105514876AEasy to clean dustImprove cleaning effectApparatus for overhead lines/cablesEngineeringSurface plate

The invention discloses an electrically adjustable electric cleaner, comprising a fixing rod and an L-shaped adjusting rod slidably connected inside the fixing rod. A fixing ring is welded to the front end of the adjusting rod, electric telescopic rods are mounted on the inner surface of the fixing ring at equal intervals, a mounting plate is connected to an end of each electric telescopic rod, a cleaning device is connected to the inner surface of each mounting plate through a connector, a storage battery is mounted on the lower portion of the fixing rod and electrically connected with an operating panel disposed on the surface of the fixing rod, and the operating panel is electrically connected with the telescopic rods. The electrically adjustable electric cleaner has adjustable openness, is suitable for cables different in size, enables convenience for dust cleaning, allows sundries cleaning, allows water to be injected into cleaning brushes so that cleaning effect is improved, and has diverse functions, thus improving cleaning efficiency of electrical equipment, lowering labor intensity of workers and reducing potential safety hazards.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

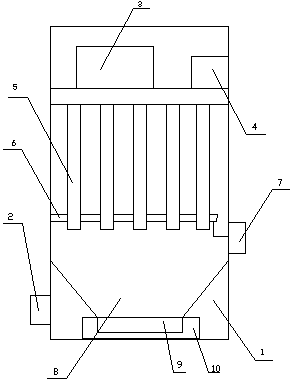

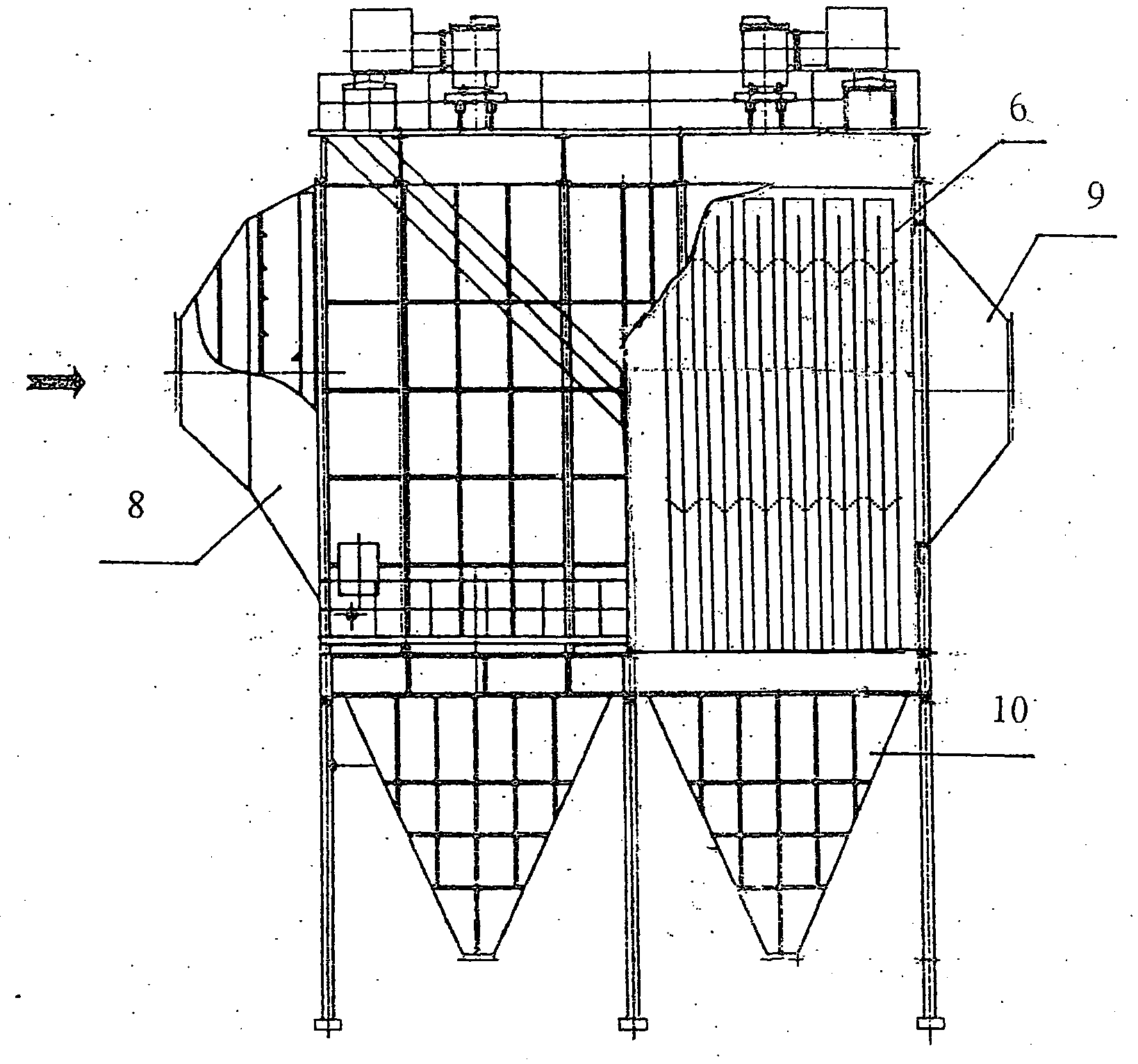

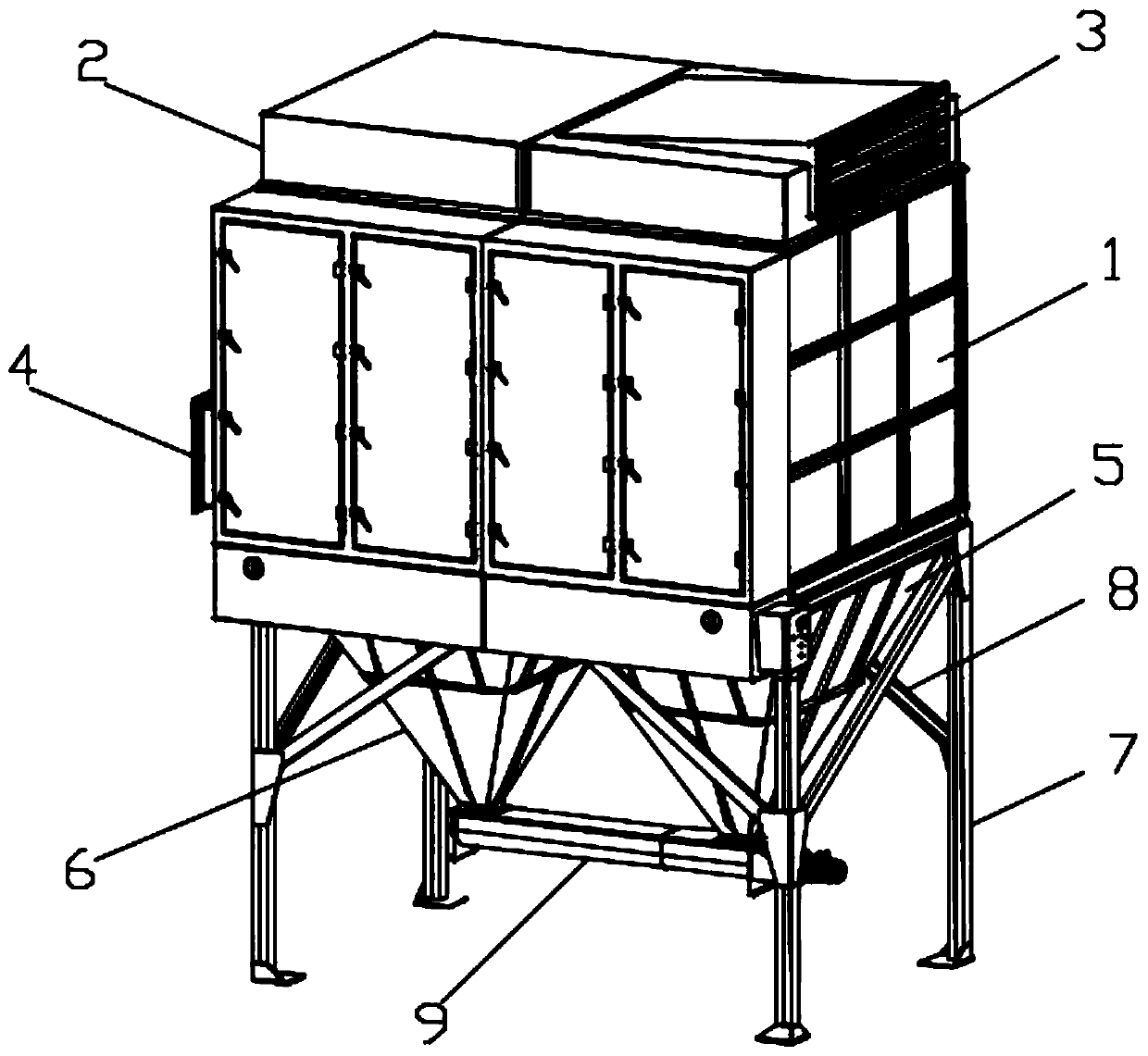

Novel dust remover

The invention relates to a novel dust remover, which comprises a steel plate case of a vertical framework. A dust outlet door and an air inlet are provided on the case, the case is divided into an upper part and a lower part, a motor and a blower fan are provided on the upper part of the case, several filter bags are fixedly arranged in the lower part of the case, a support is provided on the lower end of the filter bag, one end of the support is connected to a vibration motor, a dust bucket is provided at the lower part of the filter bag, a dust accumulation case is provided at the lower part of the dust bucket, the dust accumulation case is in a drawer type structure, the dust accumulation case is filled with clear water, and the dust accumulation case is arranged outside the dust accumulation case.

Owner:JIANGSU ZHONGLI PETROCHEM EQUIP

Biomass fuel waste heat recycling cooking range

ActiveCN103900111AImprove absorption rateIncrease profitLighting and heating apparatusStove/ranges for heating waterHearthAir blower

The invention discloses a biomass fuel waste heat recycling cooking range which comprises a hearth defined by high temperature resistant materials and an air blower. A grate bridge is arranged at the bottom of the hearth, an opening for containing a heated body is formed in the top of the hearth, an ash accumulating cavity is formed below the grate bridge, a feeding opening is formed in the hearth and extends out of the wall of the hearth through a pipe or a hopper, and an air outlet of the air blower is communicated with the ash accumulating cavity through a pipe. The biomass fuel waste heat recycling cooking range further comprises a waste heat recycling cavity, hot air pipes and an induced draft fan. The heated body is connected with the top of the hearth in a sealed mode to form a heating area, the waste heat recycling cavity is arranged to surround the hearth and separated from the heating area at the top of the hearth, the hot air pipes are arranged in the waste heat recycling cavity, one ends of the hot air pipes extend out of the waste heat recycling cavity to be communicated with the heating area at the top of the hearth, and the other ends of the hot air pipes extend out of the waste heat recycling cavity to be communicated with the induced draft fan. The biomass fuel waste heat recycling cooking range is convenient to use, and heat generated by burning biomass particle fuel can be sufficiently used.

Owner:贺曼

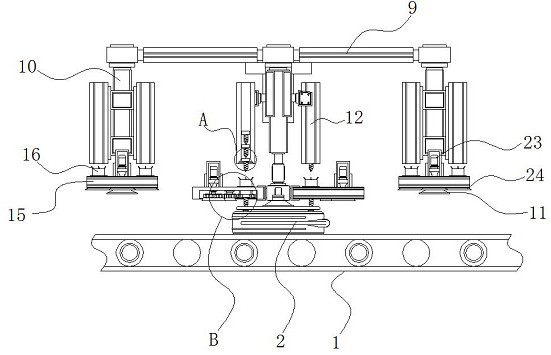

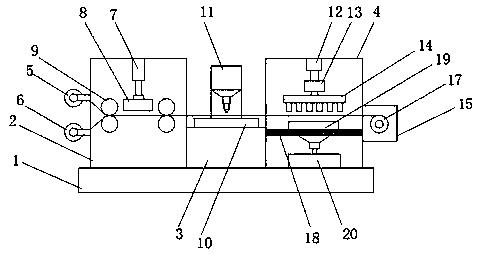

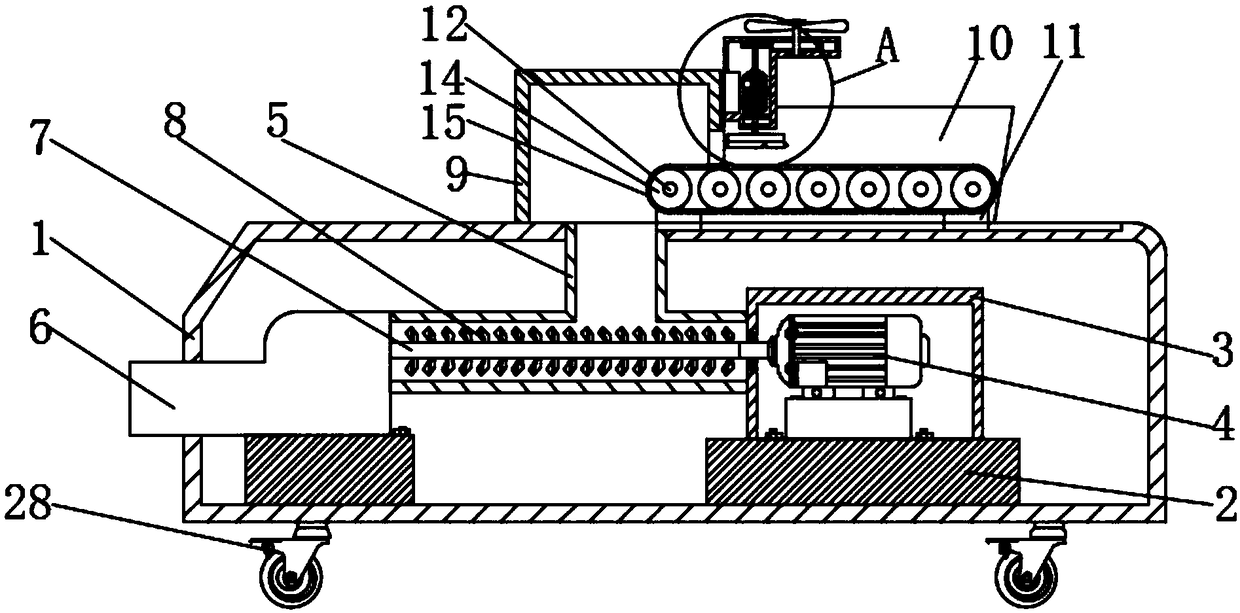

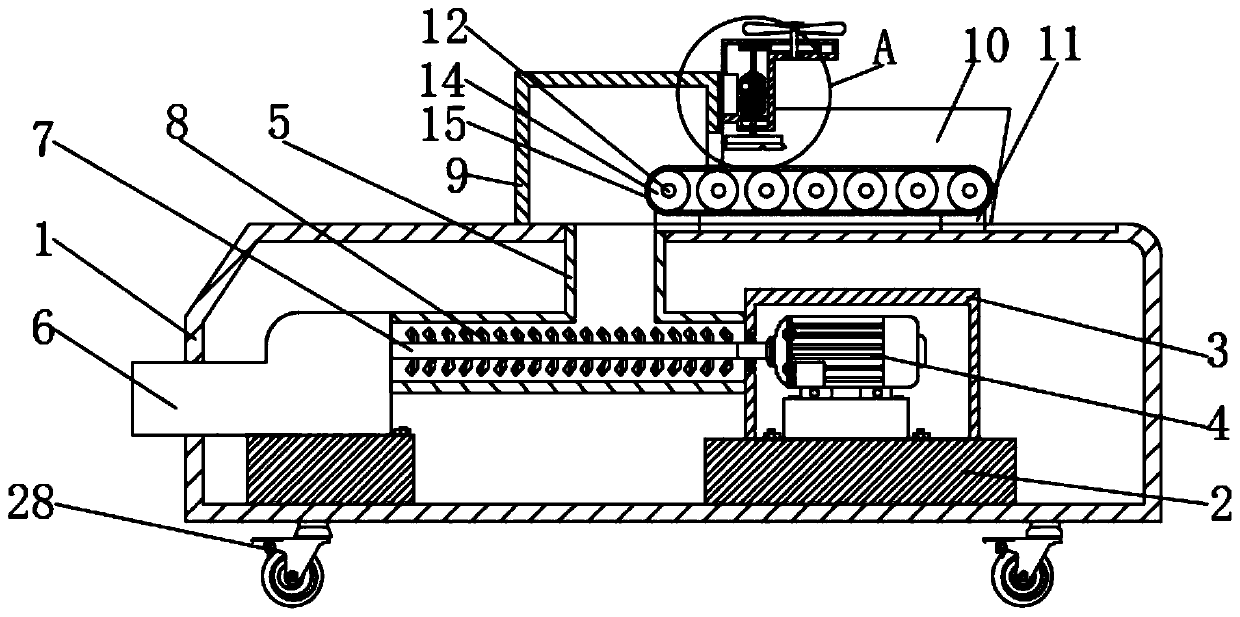

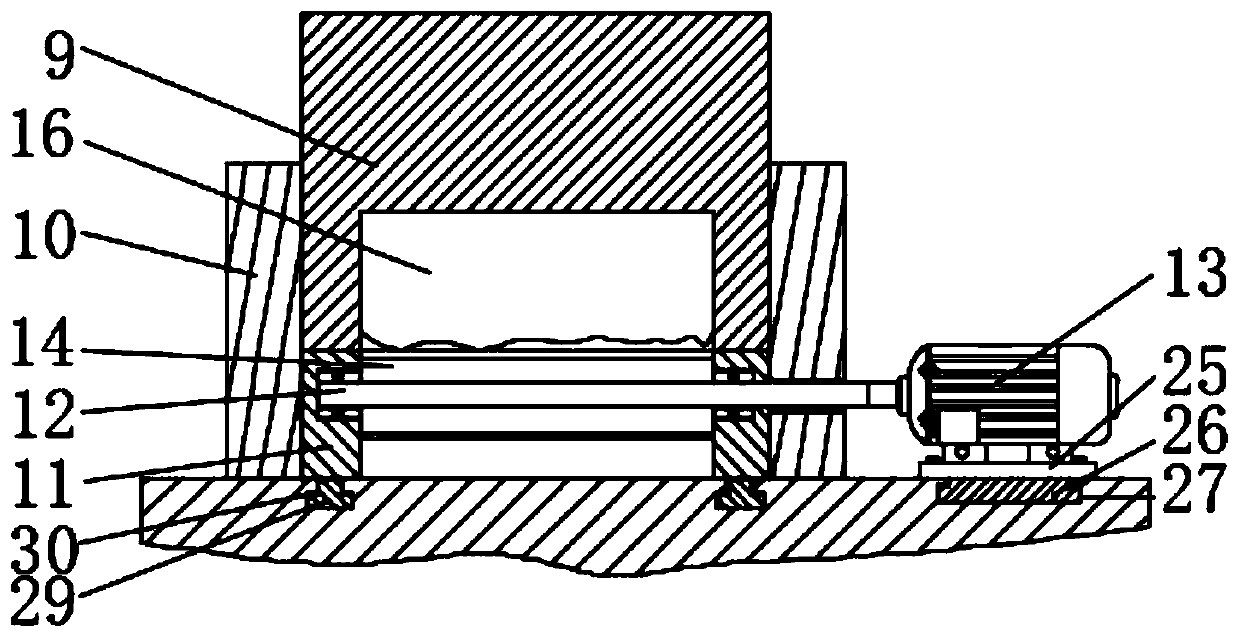

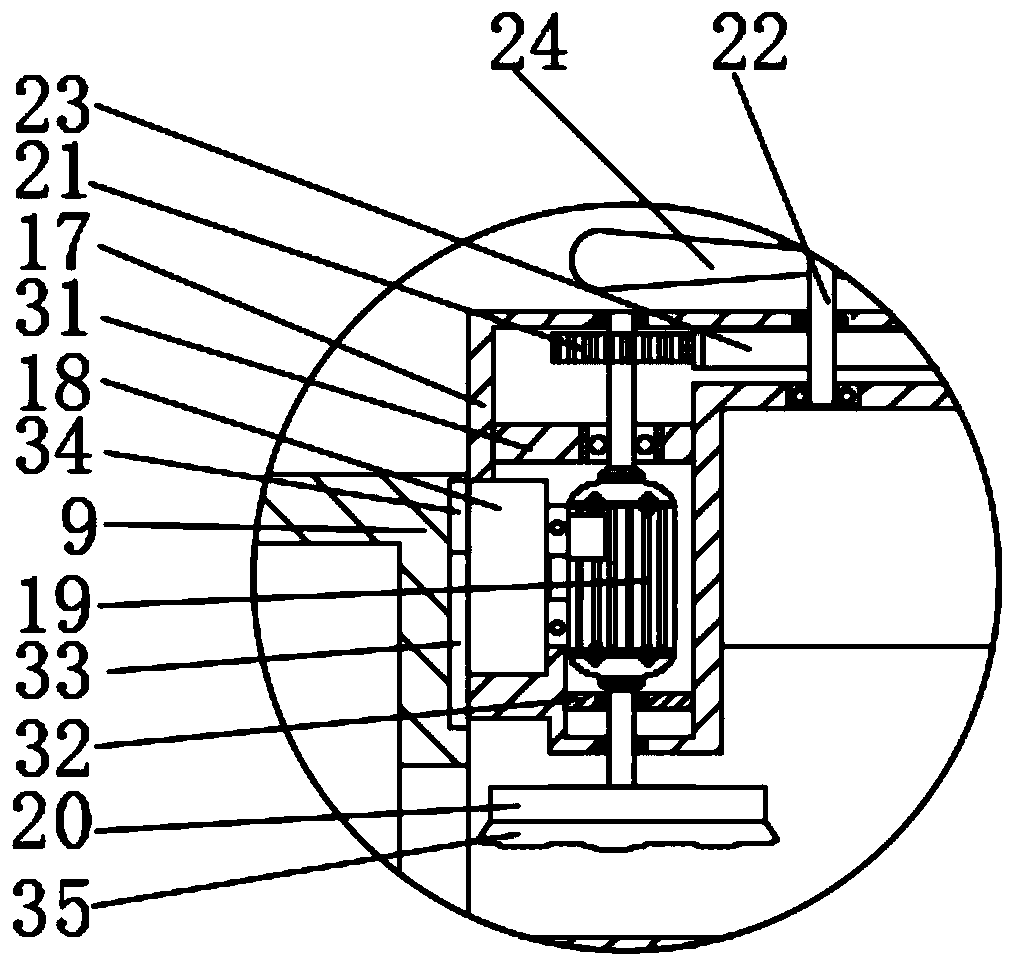

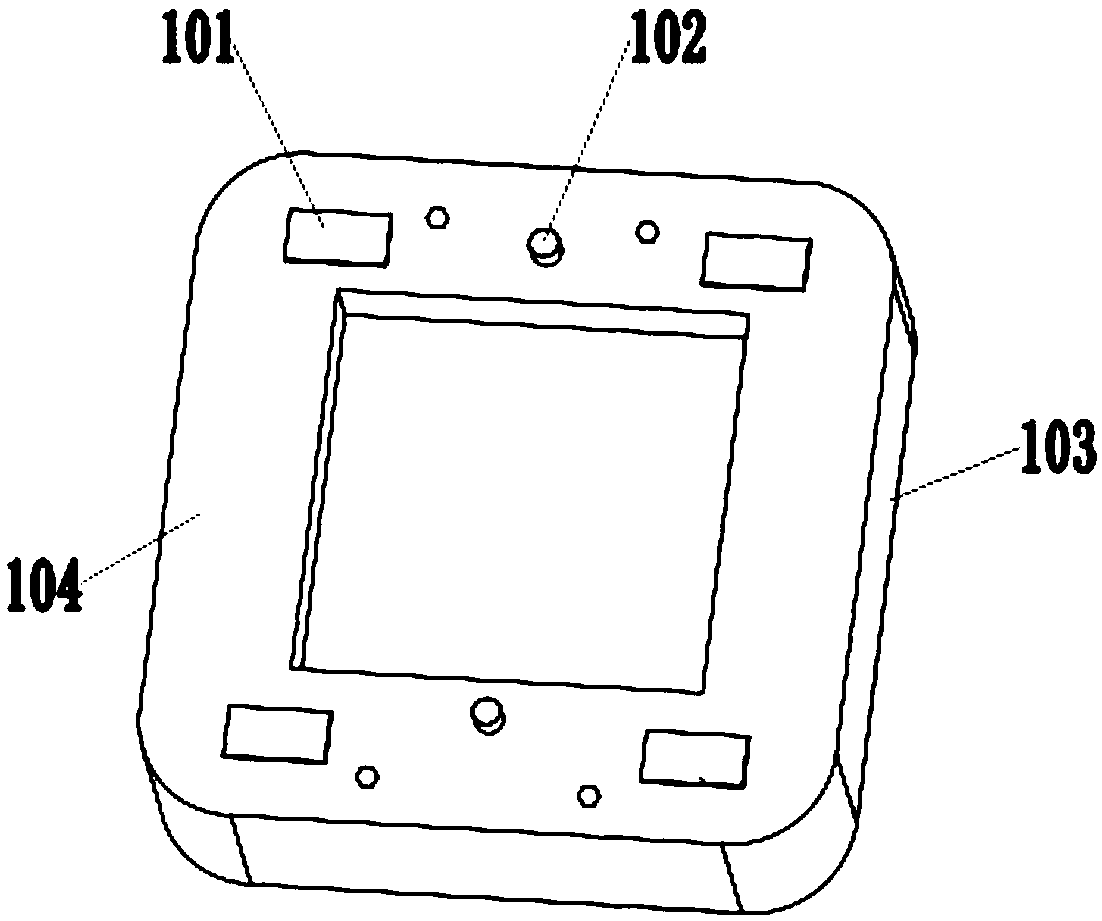

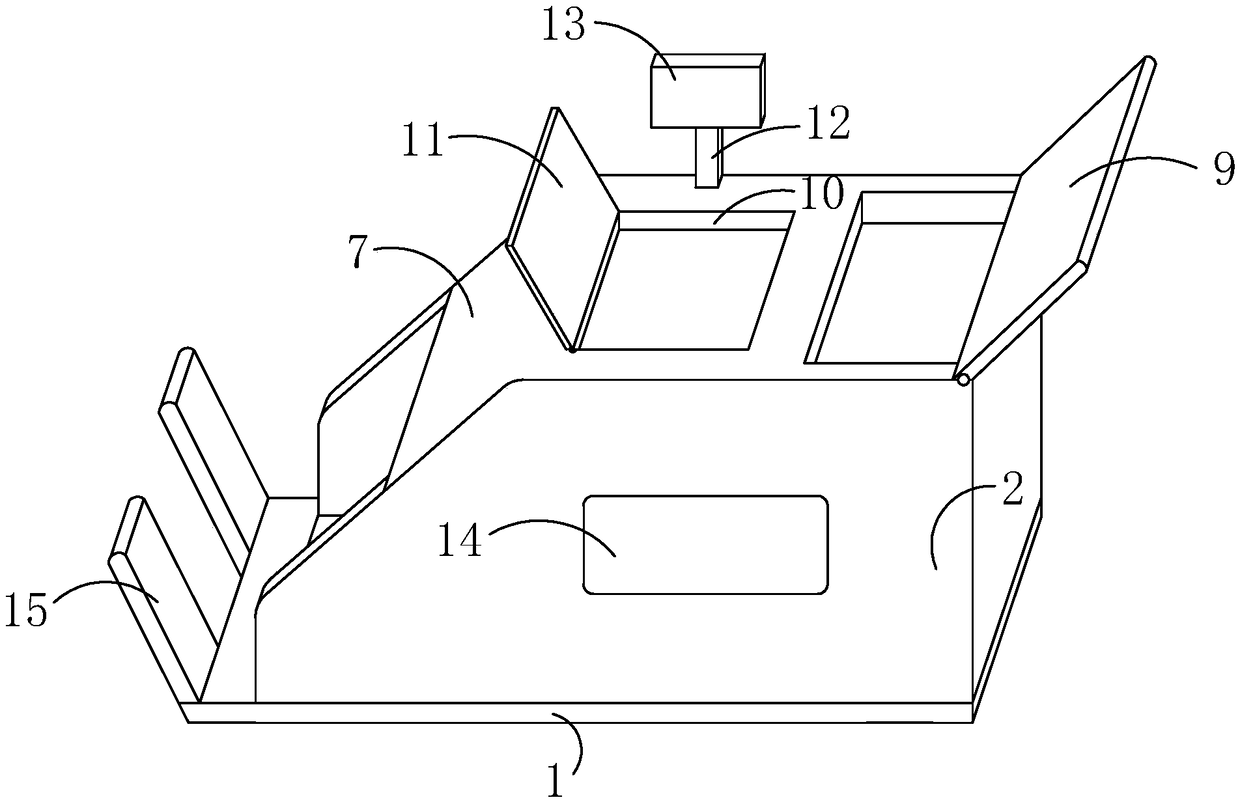

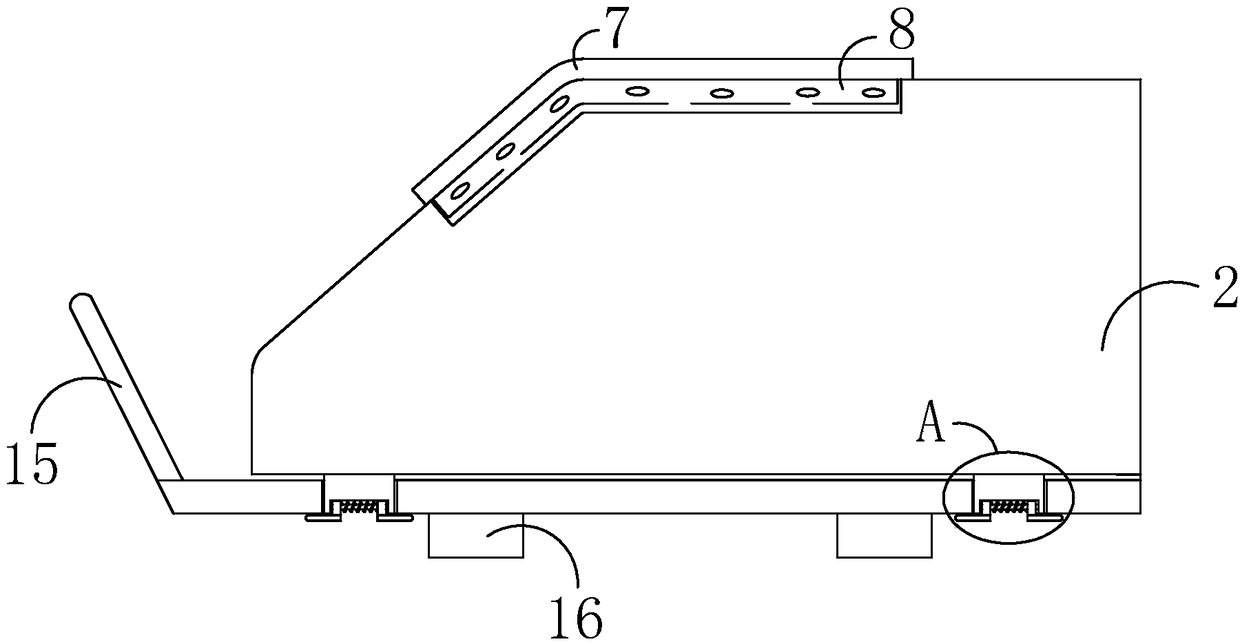

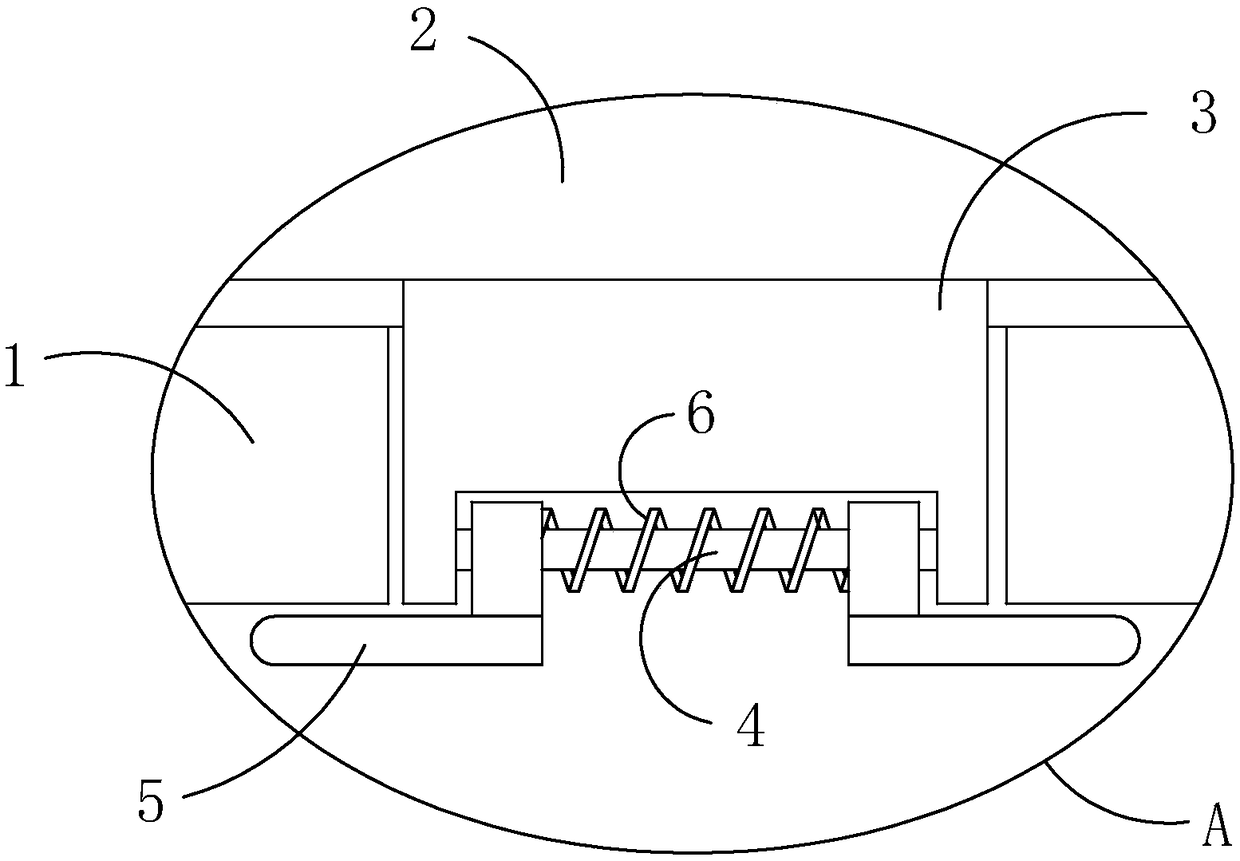

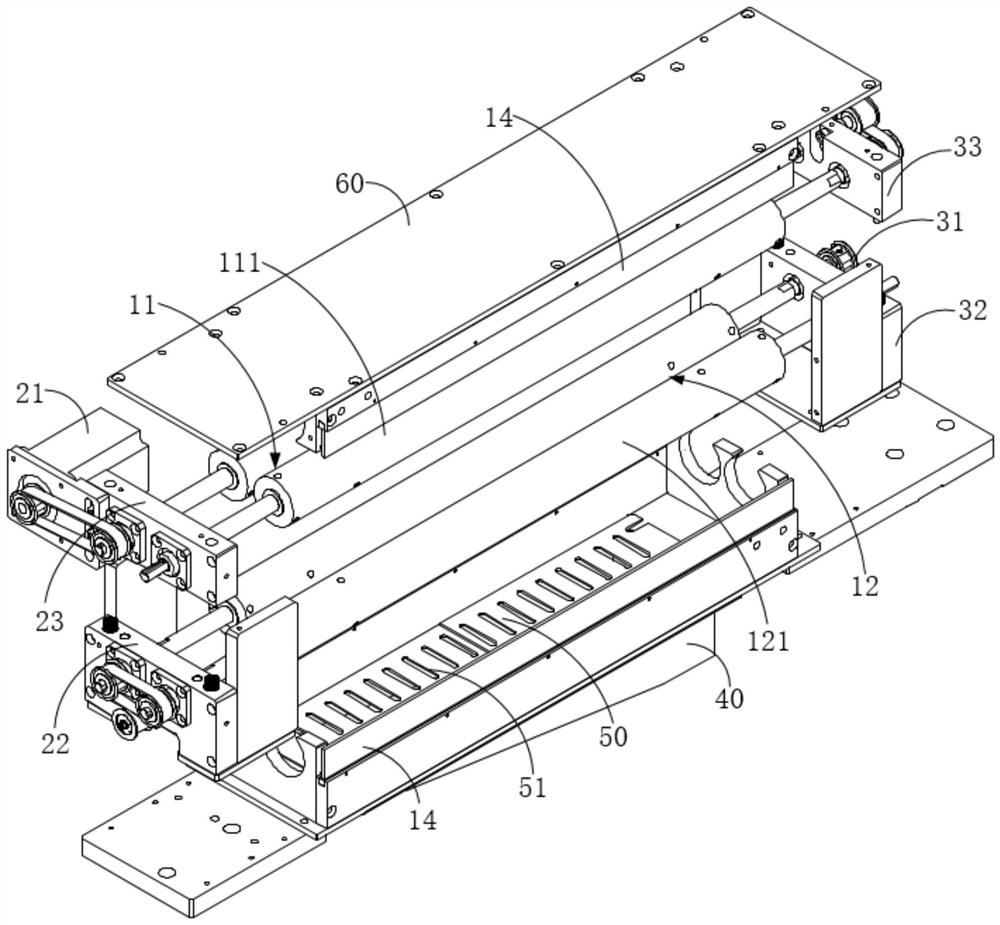

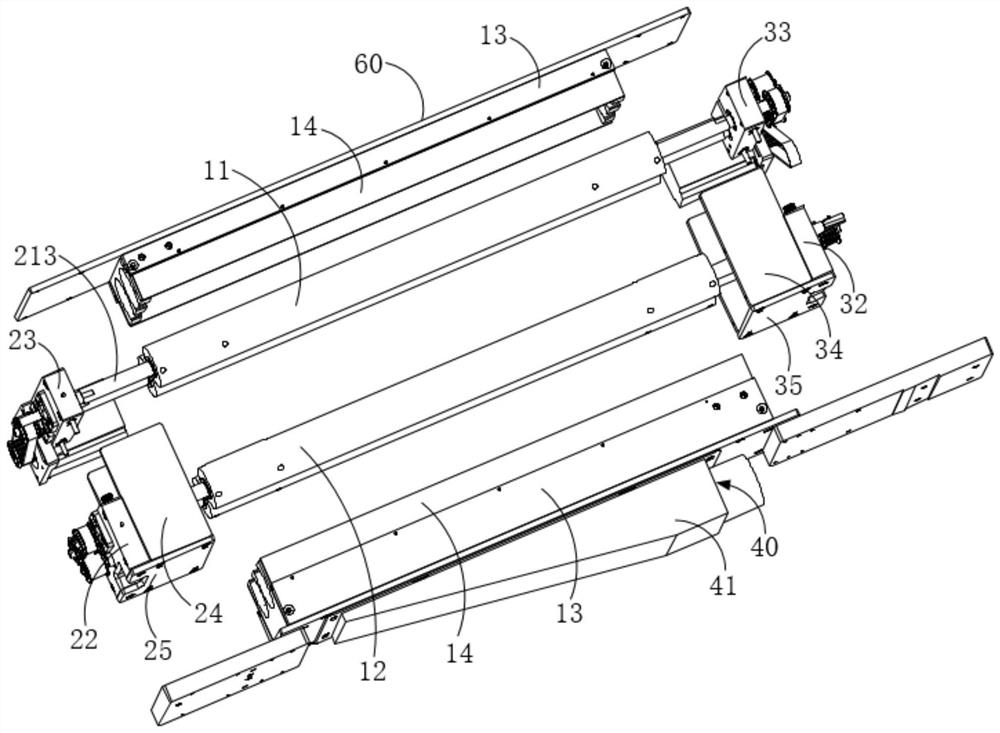

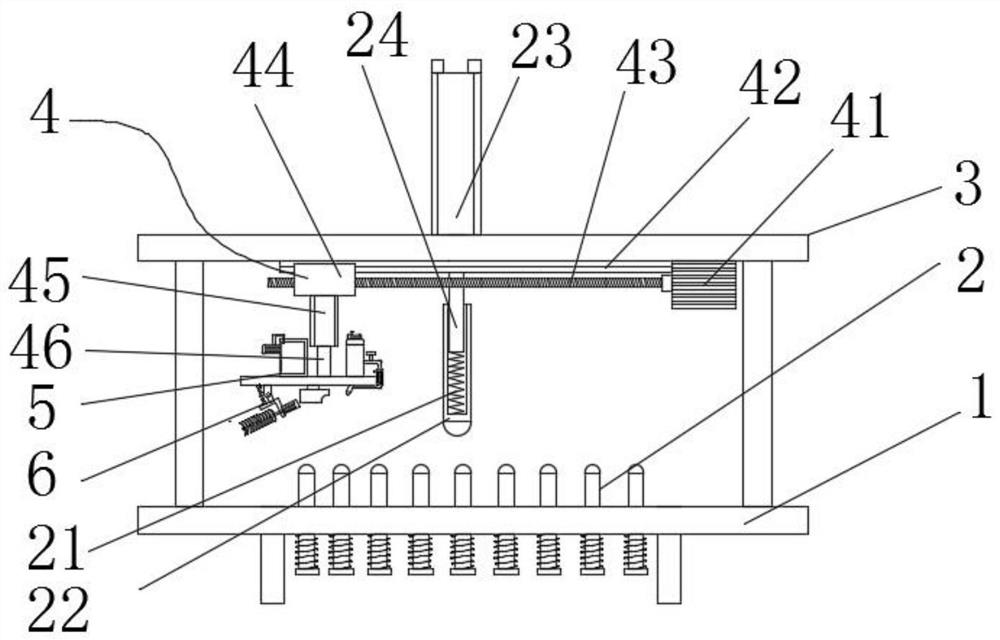

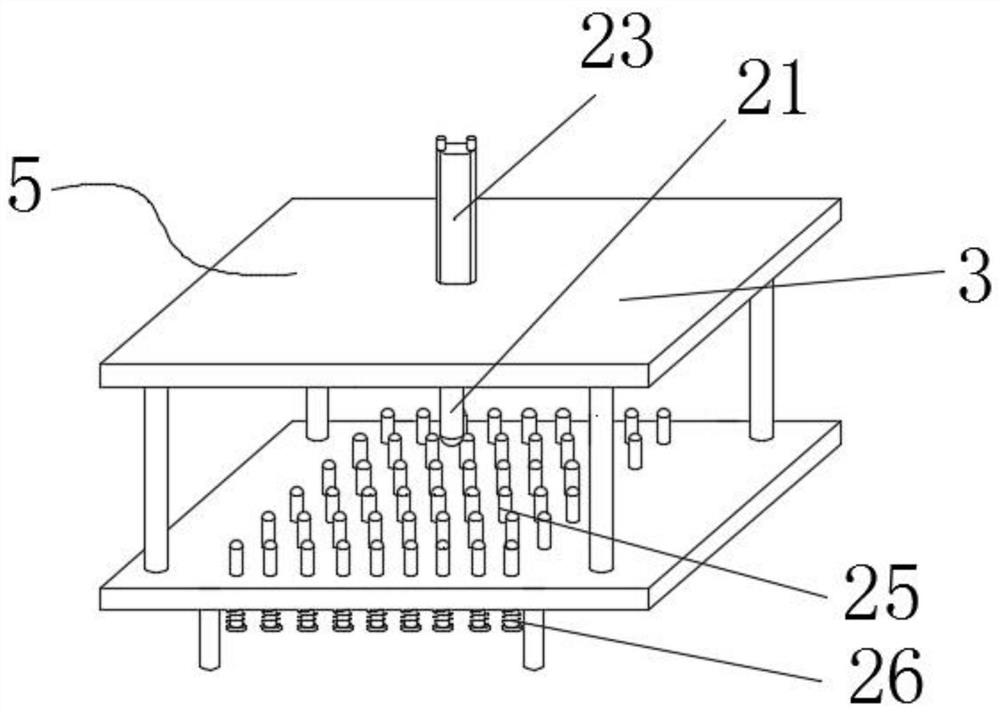

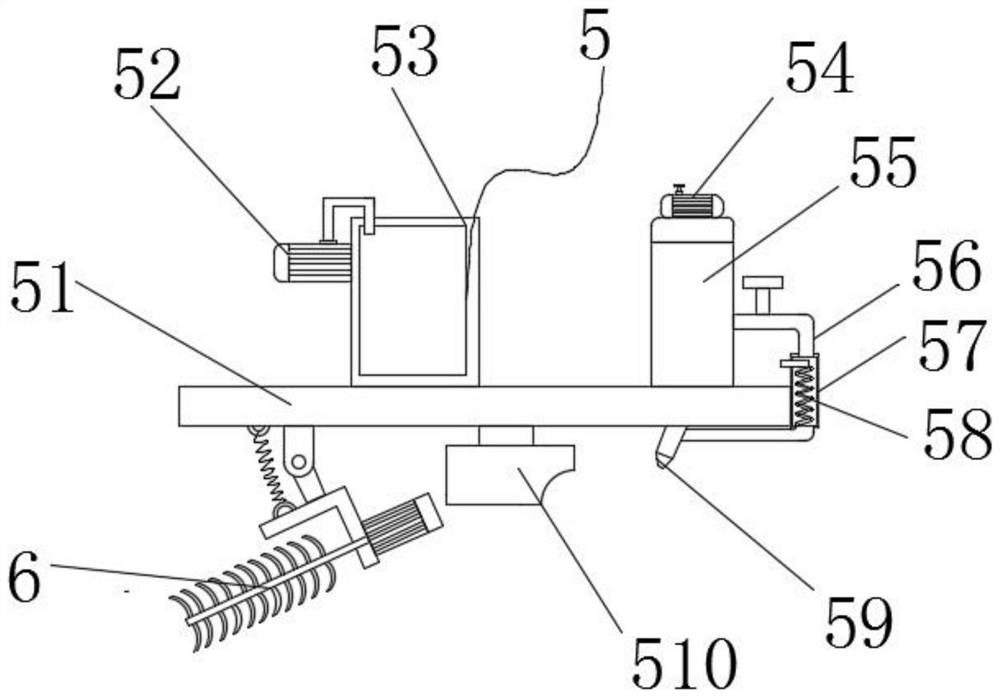

Automatic assembling device with cleaning and dust removing structure for automobile key cover plate

InactiveCN112192176AImprove assembly qualityEasy accessWork holdersCleaning using toolsDust controlStructural engineering

The invention discloses an automatic assembling device with a cleaning and dust removing structure for an automobile key cover plate, and relates to the technical field of automobile key assembling. The automatic assembling device specifically comprises a first conveyor belt and an assembling mechanism, a key main body is arranged in the middle of the surface of the first conveyor belt, and micropush rods are arranged on the two sides of the key main body; and a traceless rubber roller shaft is arranged in the middle section of the surface of the first conveyor belt, a second conveyor belt isdistributed on one side of the first conveyor belt in parallel, and the assembling mechanism is arranged between the first conveyor belt and the second conveyor belt. According to the automatic assembling device with the cleaning and dust removing structure for the automobile key cover plate, assembly line automatic assembling can be realized, assembling between the cover plate and the key main body can be completed at one time by screwing a plurality of screws at the same time, and the assembling efficiency can be improved; and meanwhile, the cover plate and the key main body can be cleanedand subjected to dust removal before and during assembling, so that dust is prevented from being left in an assembled automobile key, and the assembling quality can be improved.

Owner:深圳市顺尔通工业设计有限公司

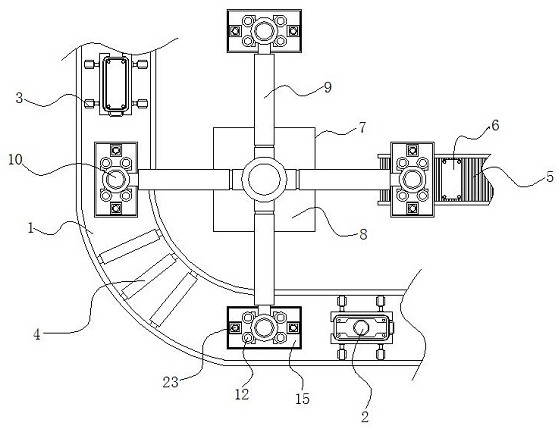

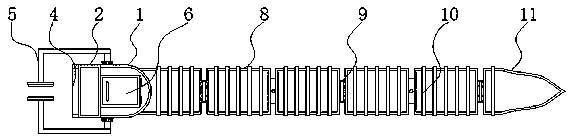

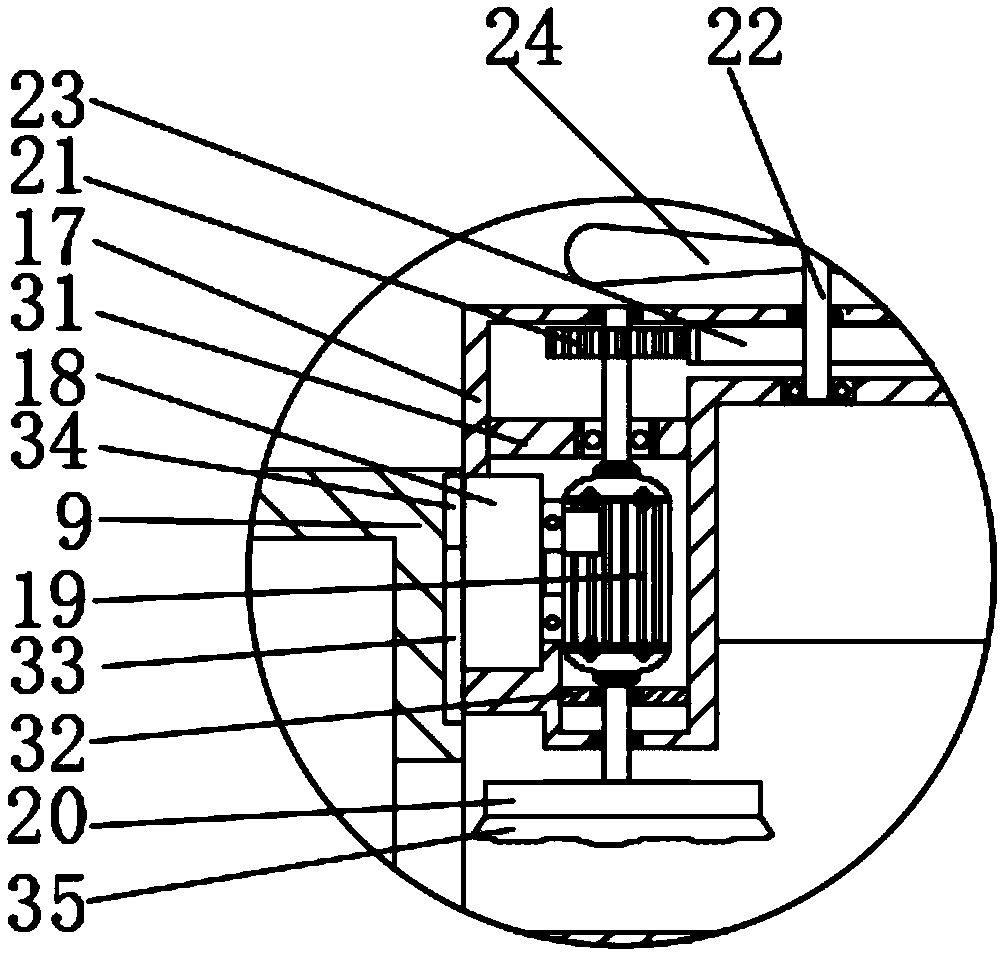

Household machine snake with clamping function in gap

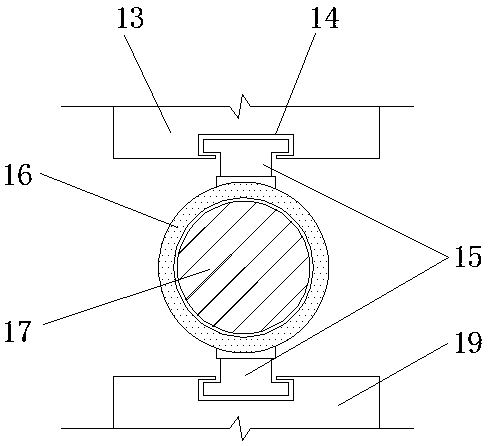

InactiveCN110744533ASmooth rotationEasy to clean dustProgramme-controlled manipulatorJointsElectrical and Electronics engineeringDust control

The invention discloses a household machine snake with a clamping function in a gap, relates to the technical field of machine snakes. The household machine snake with the clamping function in the gapcomprises a machine snake head part, clamping mechanisms and a trunk part; a fixed front shell is integrally fixed at the front part of the machine snake head part; a camera shooting mechanism is arranged at the front part of the middle part of the fixed front shell; a protection convex edge is fixed on the outer ring of the front part of the fixed front shell; and the protection convex edge andthe fixed front shell are integrally welded; the clamping mechanisms are arranged on two sides of the machine snake head part; a battery box is arranged at the upper part of the inner side of the machine snake head part; and a built-in battery pack is arranged inside the battery box. The household machine snake with the clamping function in the gap has the beneficial effects that through the arrangement of a camera in the camera shooting mechanism, an advancing path of the machine snake can be conveniently monitored in real time, a dust removing brush can be conveniently rotated through a rotating shaft, so that the front surfaces of the camera and an illuminating lamp can be conveniently cleaned and dedusted, and the influence of dust on the surface of the camera in the moving process ofthe machine snake is avoided.

Owner:DONGGUAN UNIV OF TECH

Screen type electrical deduster

InactiveCN104107760AIncrease Coulomb adsorption attractionEfficient captureElectrode carrying meansExternal electric electrostatic seperatorPhysicsCorona discharge

A screen type electrical deduster is an electrical deduster which is provided with a screen type anode plate and used to efficiently capture aerosol industrial flue-dust particles with PM less than 2.5 mu m. According to the screen type electrical deduster, a metal screen sheet with distributed meshes is fixedly installed on a plane frame, so that a screen type anode frame is prepared; also n corona discharge electrode wires fixedly arranged on a plane frame in a parallel way at equal intervals, so that a cathode frame is prepared; two same anode frames are fixedly parallelized at an equal interval, then an insulating material is used to suspend and install a parallel cathode frame at the middle of the two anode frames, so that a combined type dedusting apparatus is prepared; in the box body of the electrical deduster, 1-n dedusting apparatuses are arranged in a parallel way along the direction perpendicular to an airflow movement direction, so that a dust-absorbing electric-field system with multiple transverse dust-collecting grids is formed; and in the box body of the electrical deduster, 1-n dust-absorbing electric-field systems are installed in an array.

Owner:袁野

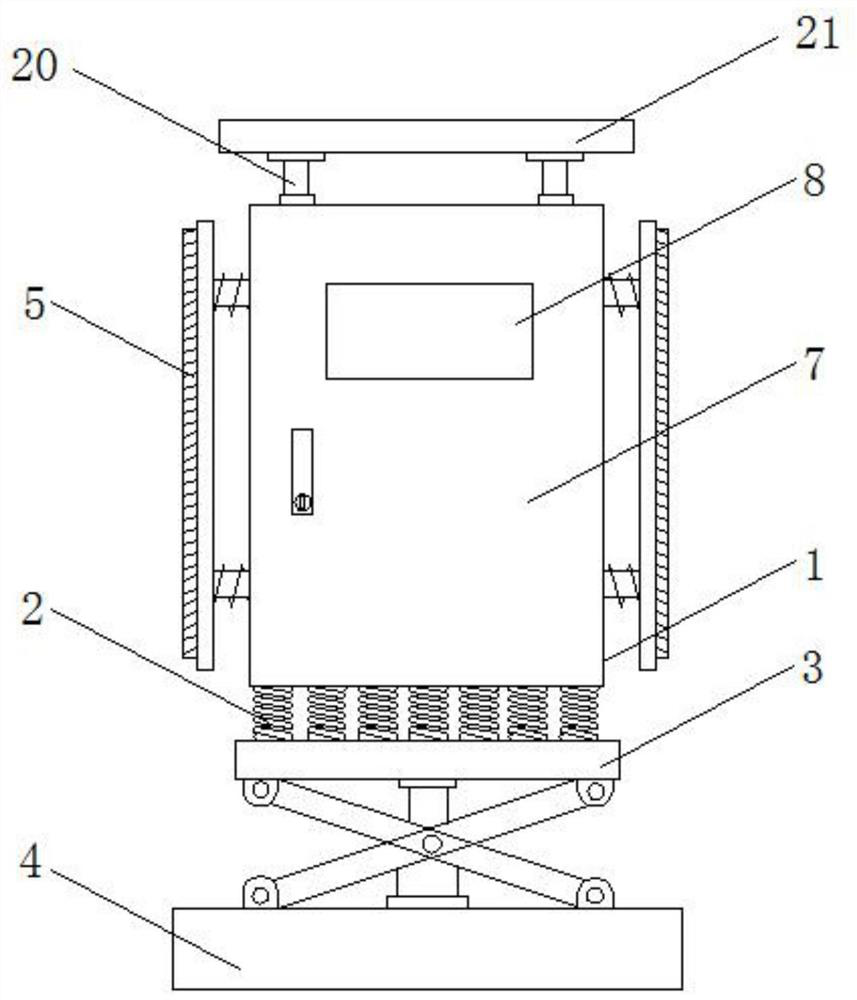

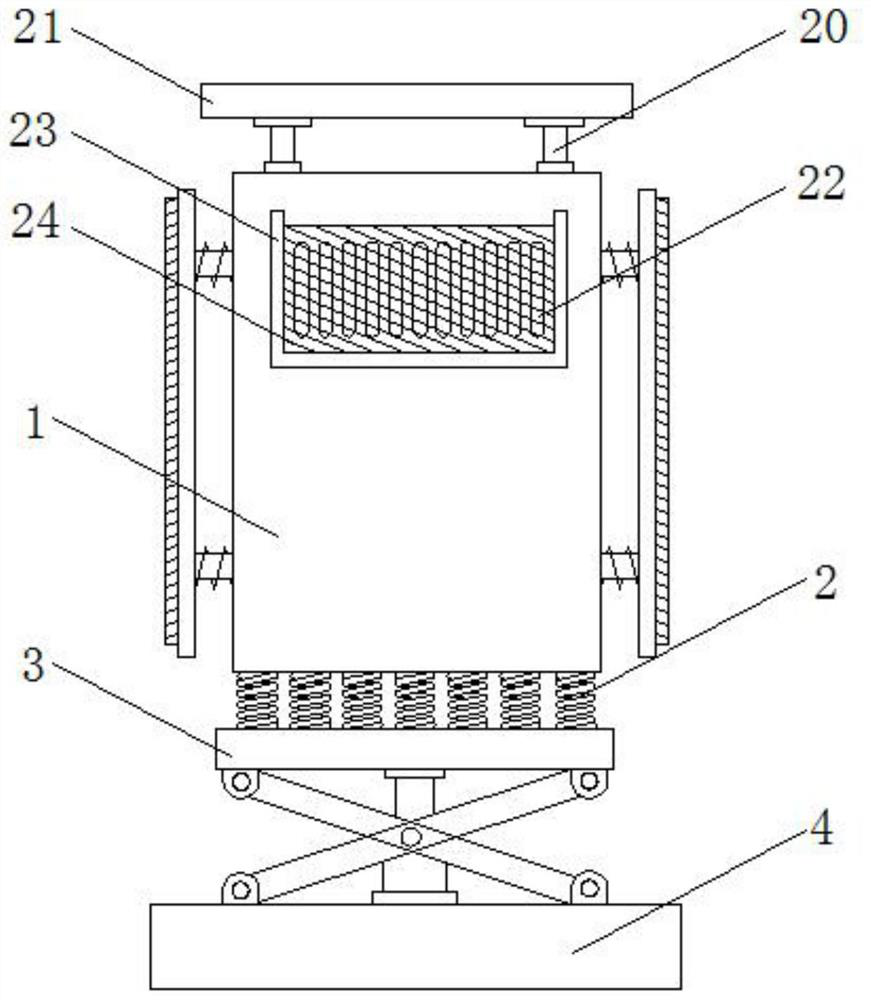

Low-voltage power distribution cabinet convenient to clean internal dust

InactiveCN113328348AEasy to cleanImprove dust removal effectBatteries circuit arrangementsDispersed particle filtrationElectric machineDust control

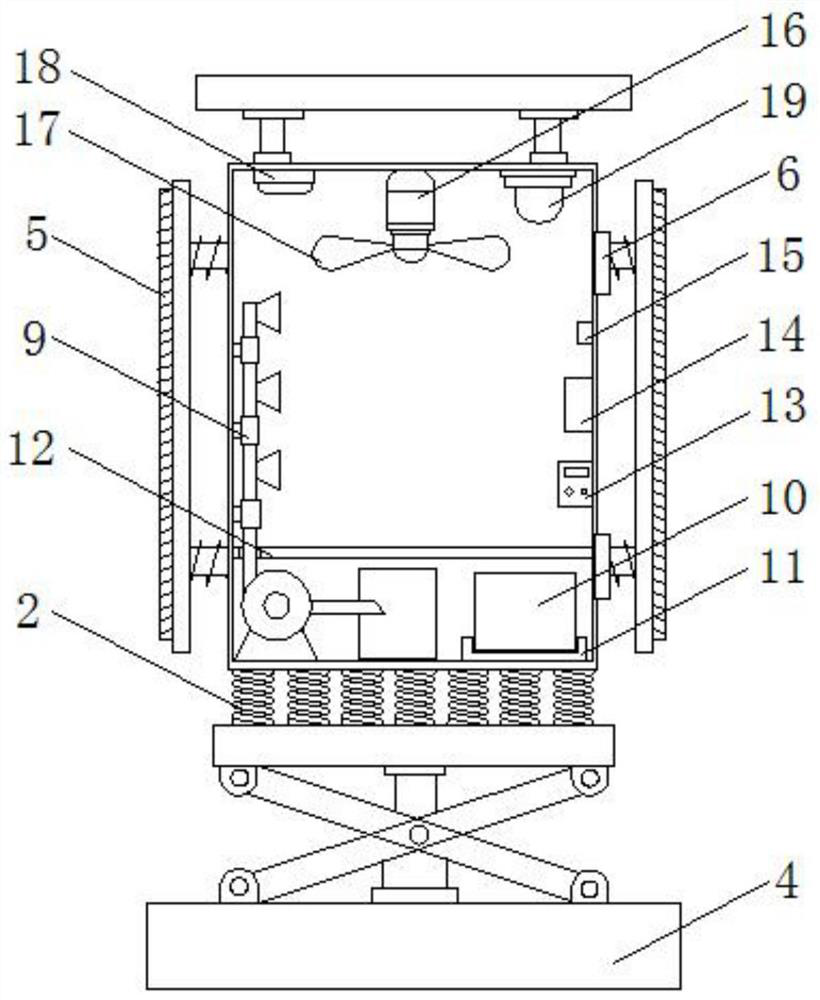

The invention discloses a low-voltage power distribution cabinet convenient to clean internal dust, which comprises a low-voltage power distribution cabinet body, protection mechanisms, a dust removal mechanism, a controller, a motor, an illuminating lamp, a solar photovoltaic panel and heat dissipation holes. Damping springs are arranged at the bottom of the low-voltage power distribution cabinet body, and the protection mechanisms are arranged on two sides of the low-voltage power distribution cabinet body. The dust removal mechanism is arranged in the low-voltage power distribution cabinet body, the partition plate is arranged above the storage battery, the controller is arranged above the electric leakage detector, the motor is arranged below the top end in the low-voltage power distribution cabinet body, and the illuminating lamp is arranged on one side of the cooling fan. The solar photovoltaic panel is arranged above the top end of the low-voltage power distribution cabinet body, and the heat dissipation holes are formed in the rear side of the low-voltage power distribution cabinet body. According to the low-voltage power distribution cabinet convenient to clean internal dust, the lifting mechanism and the dust removal mechanism are arranged, the height of the low-voltage power distribution cabinet can be conveniently adjusted through telescoping of the lifting mechanism, and dust in the low-voltage power distribution cabinet can be conveniently cleaned through work of the dust removal mechanism.

Owner:徐州华通电气科技有限公司

Sand table model and manufacturing process thereof

InactiveCN108777109AOvercome the defect of poor water resistanceImprove breathabilityEducational modelsEngineering plasticEngineering

The invention relates to the technical field of a building model, in particular to a manufacturing method of a sand table model. The method comprises the following steps of making a model map, a sandtable bottom table, a building entity, a sand table landscape, and a sand table shaping and mark. The process of making the sand table bottom table comprises the steps of making a base, a bottom plateand a side frame; coating a waterproof layer; spraying a decoration layer outside the waterproof layer; drilling a lower ventilation passage in the base; drilling an upper ventilation passage in thebottom plate. The process of making the building entity comprises the steps of performing plotting on an engineering plastic plate; spraying a decoration layer on a plotting region; performing engraving to obtain a building plate; splicing the building plate to obtain a building single unit; performing polishing and painting decoration on the surface of the building single body; firstly installinga decoration lamp inside the engineering plastic plate before the plotting on the engineering plastic plate. The invention also provides the sand table model manufactured by the process. The problemsof cleaning difficulty, poor waterproof performance and poor decoration effects in the prior art can be solved; the advantages of reasonable design, model decoration performance improvement, waterproof performance, easy-to-clean performance and long service life are realized.

Owner:国通(北京)电信工程有限公司

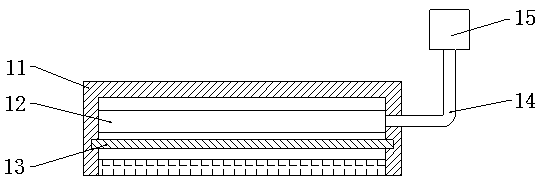

Vibration dust removal radiator for laptop

PendingCN108446002ATo achieve the purpose of coolingAchieve dust removal effectDigital data processing detailsEngineeringHigh frequency vibration

The invention discloses a vibration dust removal radiator for a laptop, belongs to the field of computer accessory equipment, and aims to solve the problem that a heat dissipation effect is likely tobe affected since laptop fan dust can not be easily cleaned in the prior art. The vibration dust removal radiator comprises a radiator body, wherein the radiator body is provided with a suction opening communicated with a laptop heat dissipation hole; the radiator body is provided with a vibration dust removal device; the vibration dust removal device comprises a connecting rod which is arranged in the suction hole and can carry out high-frequency vibration on a vertical surface; and one end of the connecting rod is provided with a vibration sheet in contact with a fan heat dissipation fan. The vibration dust removal radiator is used for the laptop.

Owner:郑州天点科技有限公司

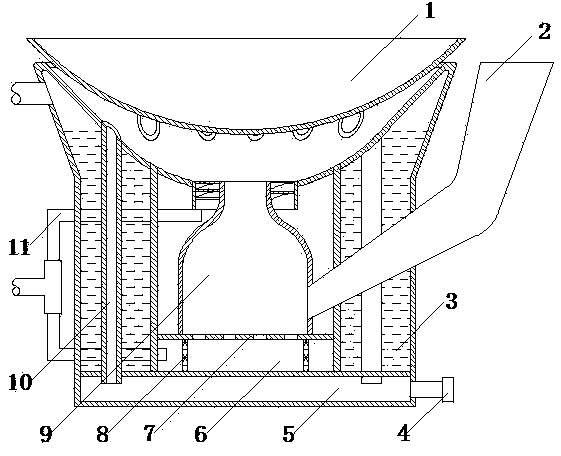

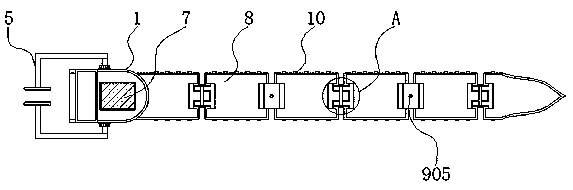

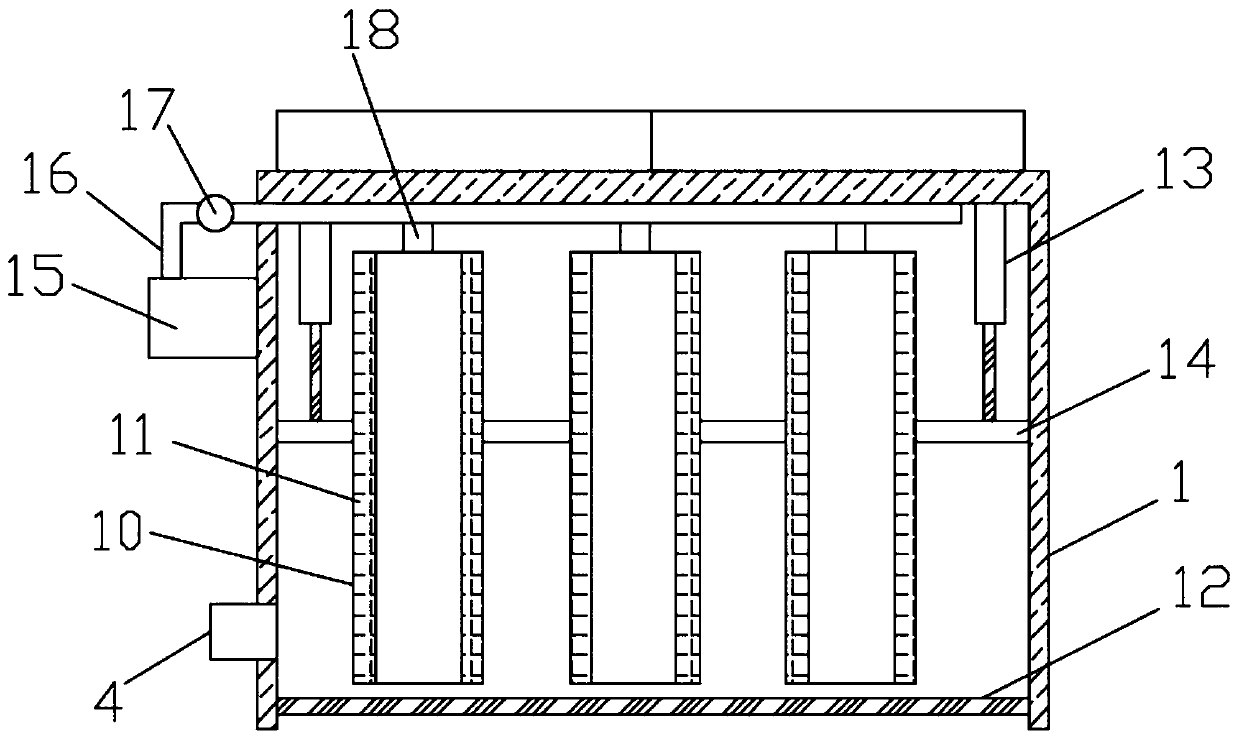

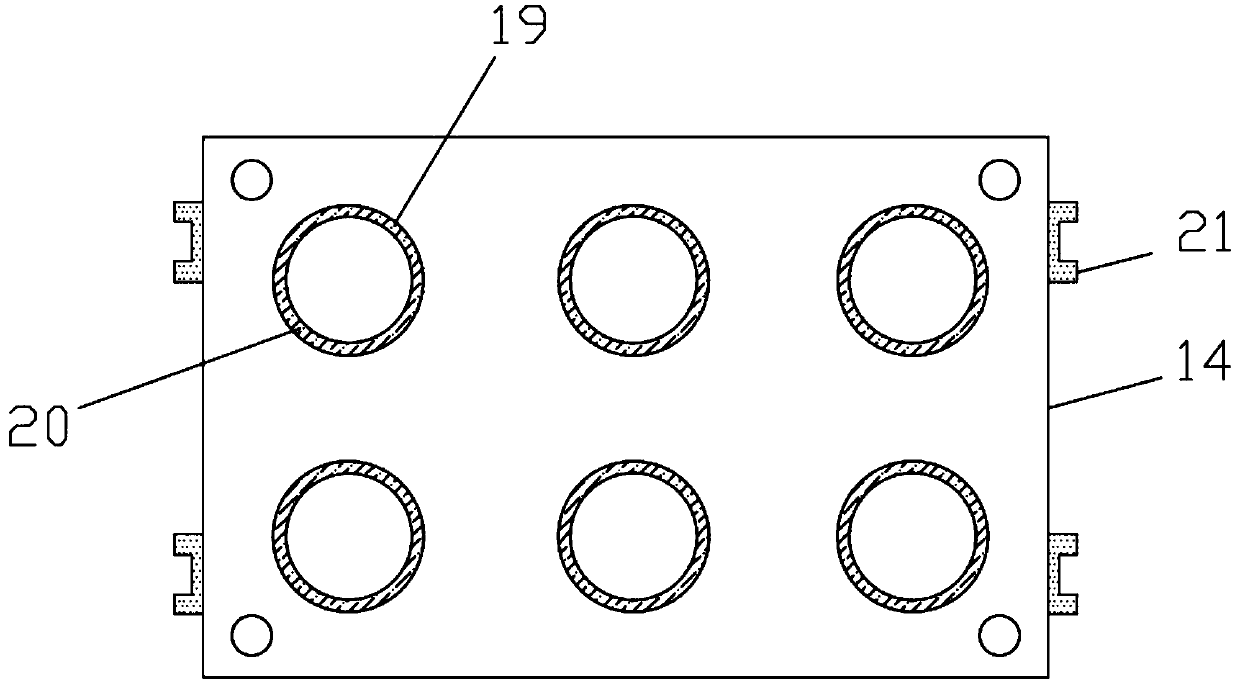

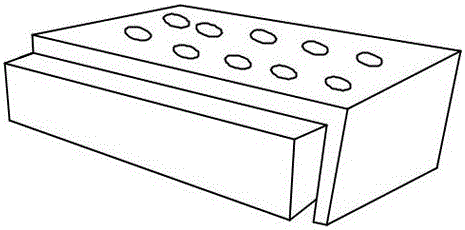

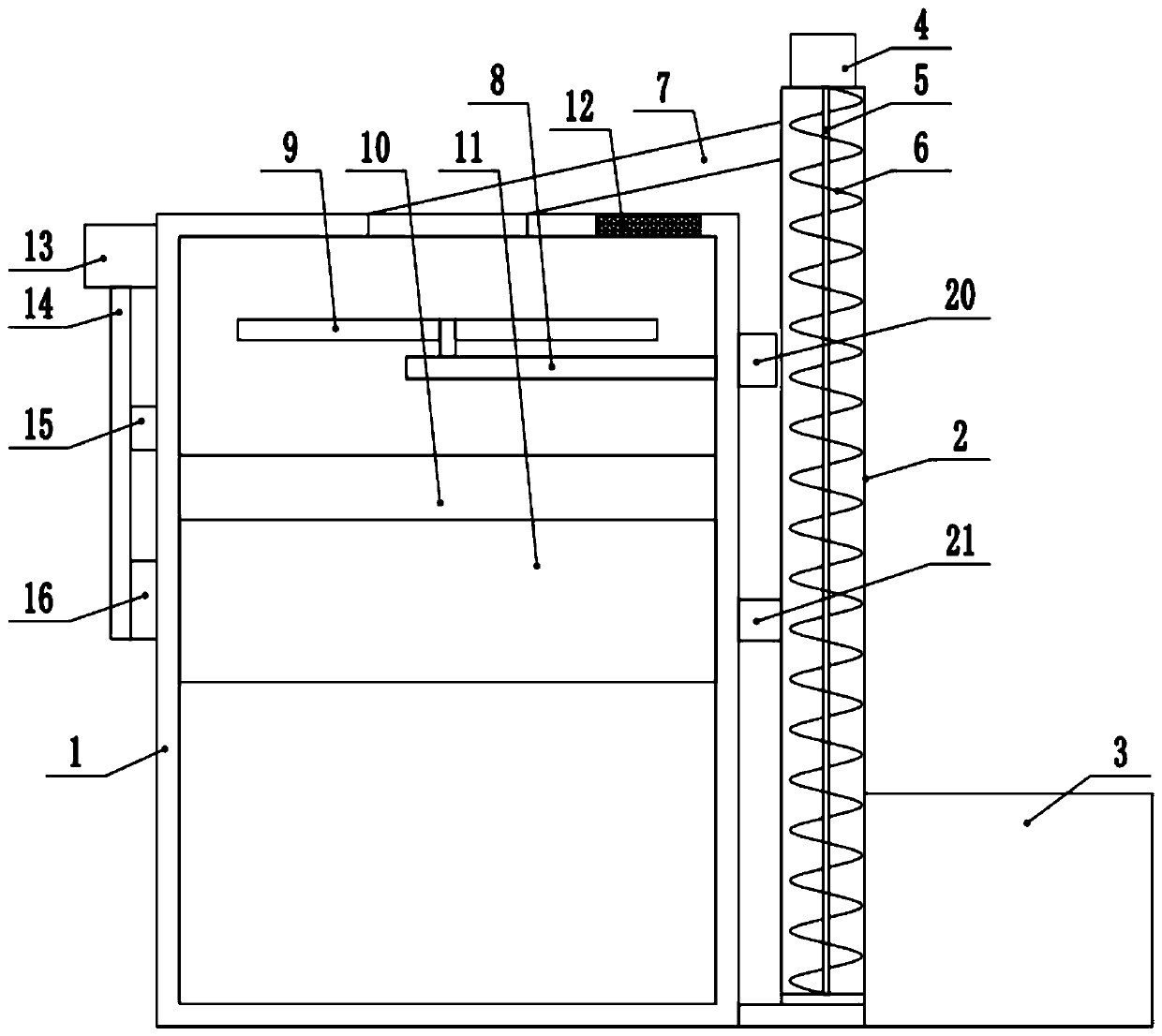

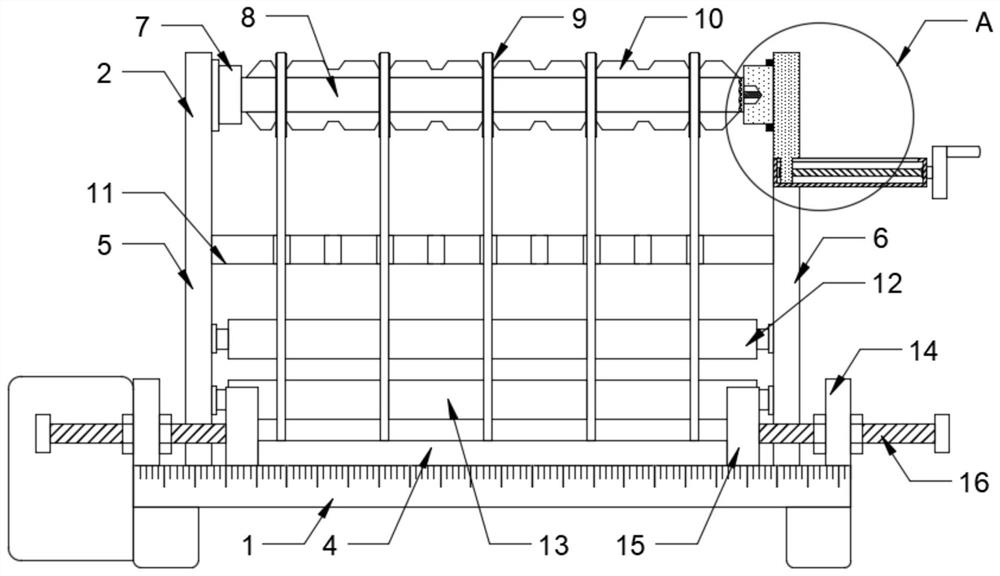

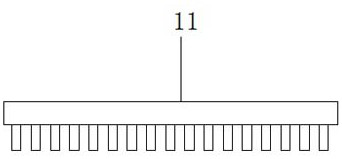

Convenient-to-clean flat bag-type dust collector for glutinous rice processing

InactiveCN110694374AGood removal effectEasy to cleanGas treatmentDispersed particle filtrationBaghouseAgricultural engineering

The invention discloses a convenient-to-clean flat bag-type dust collector for glutinous rice processing. The flat bag-type dust collector comprises a purification chamber; the upper end of the purification chamber is provided with an air cavity plate; a first ash bucket and a second ash bucket are arranged at the bottom end of the purification chamber in parallel; support frames are respectivelyarranged at edge corners of the bottom end of the purification chamber; a cross stabilizing rod is arranged between each two adjacent groups of the support frames; ash discharging cabinet are respectively arranged at the bottom ends of the first ash bucket and the second ash bucket; three groups of bags are arranged inside the purification chamber in parallel; a fine net is surround on the inner wall of each bags; and an ash discharging plate is arranged near the bottom end of the purification chamber. According to the flat bag-type dust collector provided by the invention, dust attached to the bags in the purification chamber can be easily cleaned out, and local vibration of the first ash bucket and the second ash bucket can be promoted, so that dust is prevented from being accumulated oninner walls of the first ash bucket and the second ash bucket after long-term use, cleaning and dust discharge are facilitated, ash can be well discharged through an ash discharge port, thus automatic ash discharge is realized, and high practicability is achieved.

Owner:凤台县晶谷粮油股份有限公司

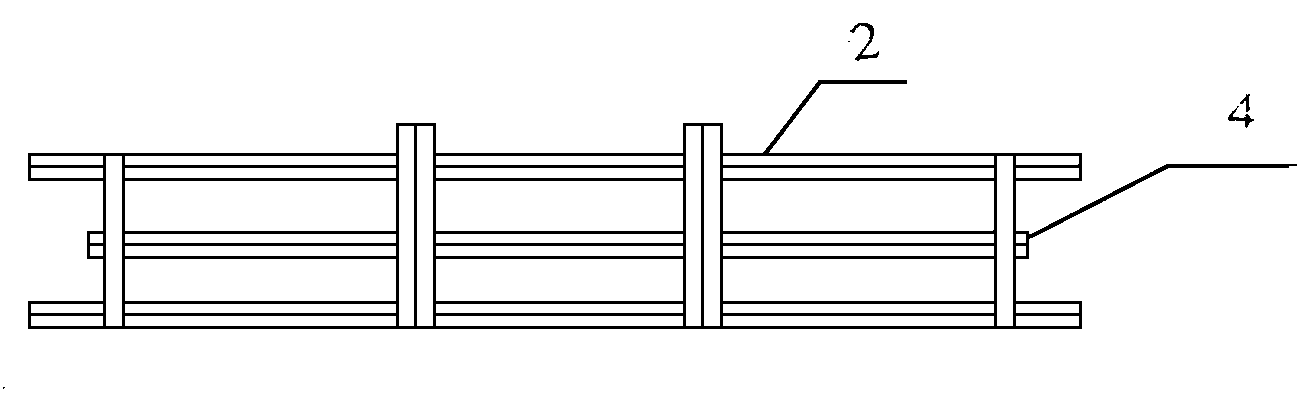

Continuous automation sewing device

The invention relates to a continuous automation sewing device. The device comprises a base, wherein a drape removal box, a storage box and a dust collection box are arranged at the top of the base from the left part to the right part in sequence; the drape removal box, the storage box and the dust collection box are fixedly connected; a first cloth laying rack and a second cloth laying rack are fixedly arranged on one side of the drape removal box; the first cloth laying rack is positioned above the second cloth laying rack. The device has the advantages that the compactness between two layers of cloth can be improved through the arrangement of four groups of cloth pressing rollers, sewing is convenient, the cloth required to be sewn is convenient to lay through the arrangement of the first cloth laying rack and the second cloth laying rack, the height of an ironing head can be adjusted through the arrangement of a first electric expansion link, the cloth is convenient to iron, occurrence of drapes on the surface of the cloth is prevented, the sewing quality is not affected, the height of a cleaning brush is convenient to adjust through the arrangement of a second electric expansion link, a first driving motor can drive the cleaning brush to rotate, and cleaning and dust collection are conveniently performed on the surface of sewn cloth.

Owner:SUZHOU KAICHENG SEWING EQUIP

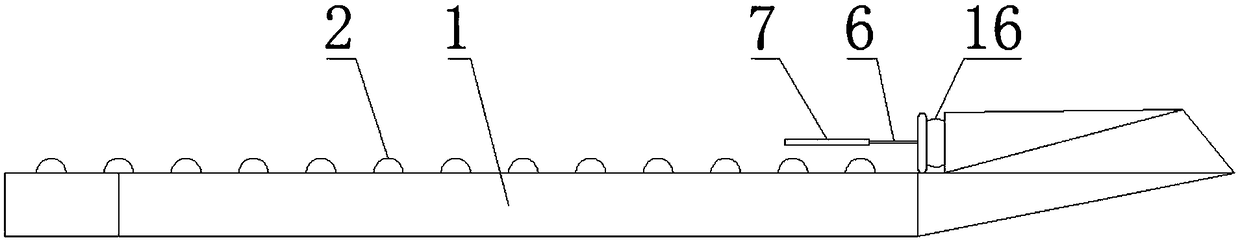

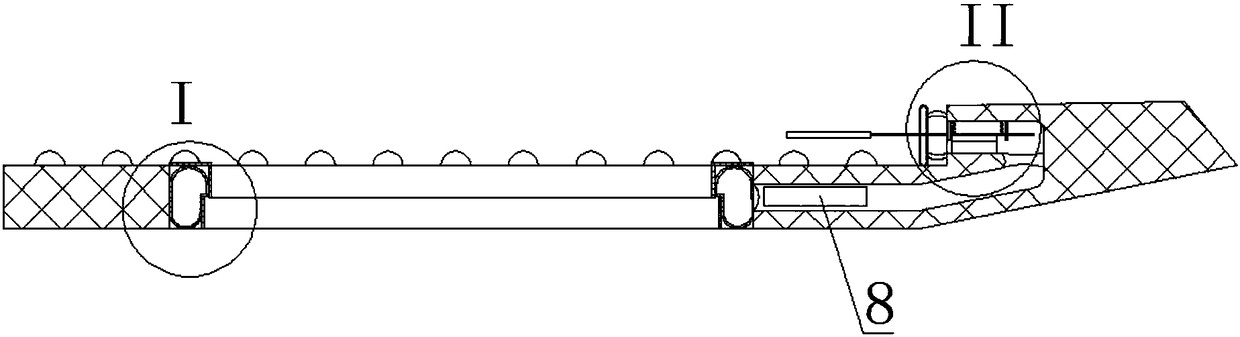

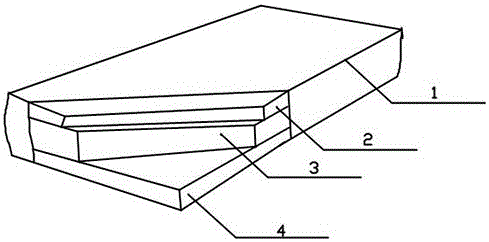

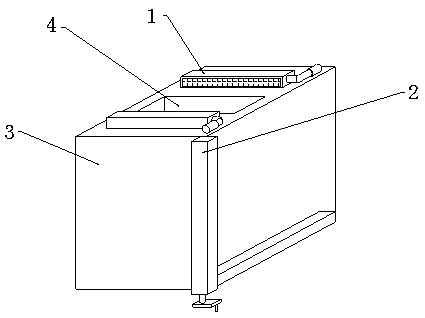

Multifunctional coir mat used for college dormitories

InactiveCN106037344AKeep dryImprove moisture resistanceStuffed mattressesSpring mattressesFiberWater vapor

The invention discloses a multifunctional brown mat for college dormitories, which comprises a cloth cover (1) and a brown mat body, the cloth cover (1) is covered on the brown mat body, and the brown mat body is a moisture-proof layer (2 ), palm cushion layer (3), dust accumulation layer (4), cloth cover (1) is a fiber cotton cover with zipper, and the moisture-proof effect is achieved by using the color-changing silica gel desiccant in the moisture-proof layer to absorb the water vapor in the palm cushion, The effect of dust removal is achieved through the drawable wooden box of the dust layer, which is suitable for damp student dormitories.

Owner:成都开悦家居用品有限公司

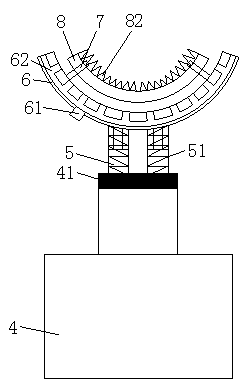

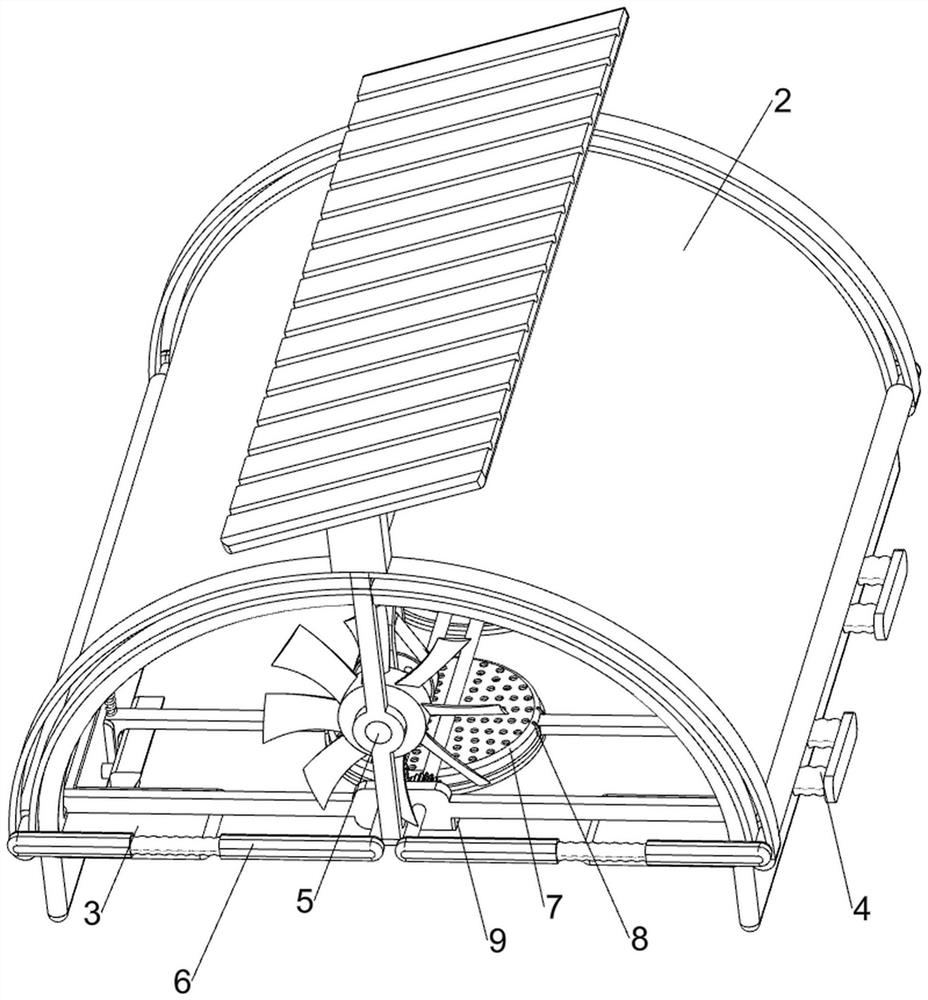

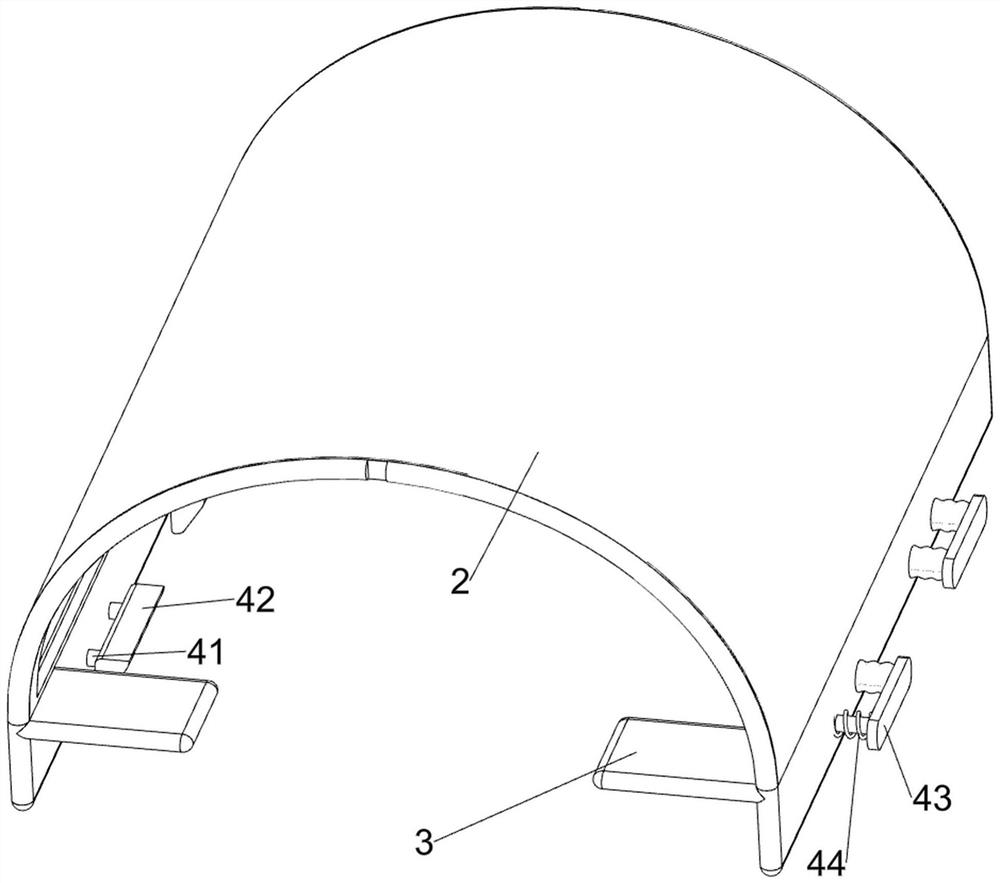

Dustproof device for ventilation of closed cooling tower

ActiveCN113532184AEasy to clean dustEasy to cleanCorrosion preventionHeat exchange apparatusStructural engineeringMechanical engineering

The invention relates to a dustproof device, in particular to a dustproof device for ventilation of a closed cooling tower. The dustproof device for ventilation of the closed cooling tower aims to achieve the technical effects that continuous ventilation can be kept, and dust can be conveniently cleared. According to the technical scheme, the dustproof device for ventilation of the closed cooling tower comprises the closed cooling tower, an arc-shaped plate, clamping plates, a clamping mechanism and a ventilation mechanism, wherein the arc-shaped plate is arranged at the upper part of the closed cooling tower, the two clamping plates are symmetrically arranged on the left side and the right side of the inner side of the arc-shaped plate, the clamping mechanism is arranged on the outer side of the arc-shaped plate, and the ventilation mechanism is arranged on the arc-shaped plate. The dustproof device achieves the effects that continuous ventilation can be kept, and dust is convenient to clear.

Owner:江西方舟流体科技有限公司

Food processing machine with good dustproof effect

ActiveCN109158178AImprove dustproof effectEasy to useFouling preventionCleaningElectric machineryFan blade

The invention discloses a food processing machine with a good dustproof effect. The food processing machine comprises a food processing machine main body, wherein a first fixing base is fixedly connected with the right side of the bottom of the food processing machine main body. Due to adoption of the food processing machine main body, the first fixing base, a transmission tank, a first motor, a crushing tank, a discharge hole, a first rotating shaft, a crushing blade, a feeding tank, a baffle plate, a support rack, a second rotating shaft, a second motor, a barrel, caterpillar bands, a firstbrush, a cleaning tank, a second fixing base, a double-axis motor, a rotating disc, a first gear, a third rotating shaft, a second gear, fan blades, a third fixing base, a first sliding block and a first chute, the problems that dust can be easily introduced when materials are fed, a poor sanitary environment can be resulted, and dust can be easily dropped into a feeding hole after the machine isstopped since materials are fed into a conventional food processing machine from an opened feeding hopper, can be solved, and the food processing machine with the good dustproof effect has the advantages of being good in dustproof effect and is convenient for users to use.

Owner:天长市康盈米业有限公司

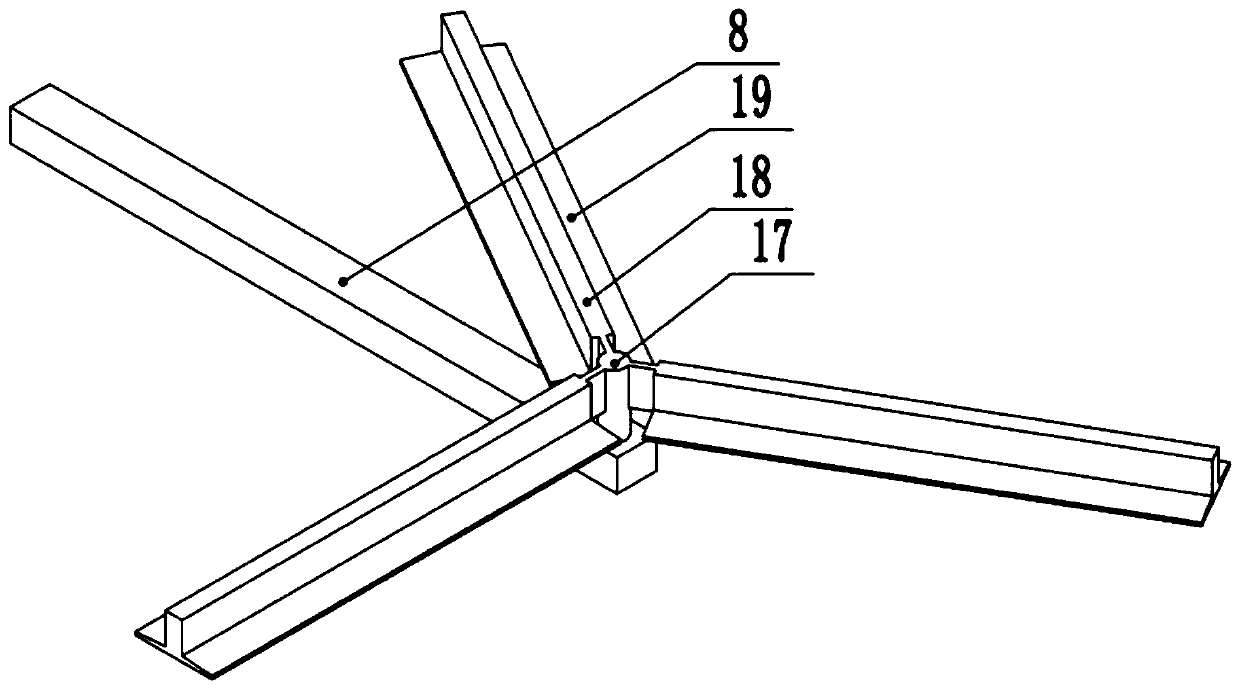

Multi-stage unhulled rice dust removing device for processing rice

InactiveCN110813839AImprove dust removal effectEasy to remove dust by windGas current separationCleaning using toolsAgricultural scienceAgricultural engineering

The invention discloses a multi-stage unhulled rice dust removing device for processing rice, and relates to the technical field of rice processing. The multi-stage unhulled rice dust removing devicecomprises a dust removing box, wherein a feed lifting mechanism is fixed on one side of the dust removing box, a first fixed rod is arranged at the upper part in the dust removing box and fixedly connected with the dust removing box, a dispersing device is arranged at the end part of the first fixed rod, a brushing dust removing device is arranged below the dispersing device and comprises an outerfixed barrel, the outer fixed barrel is coaxially and rotationally connected with a second rotating rod, and fixing rings are arranged at two ends in the outer fixed barrel. Unhulled rice can be mechanically and automatically fed by the feed lifting mechanism, and the unhulled rice which is being discharged can be dispersed by the dispersing device, so that wind dust removal is facilitated; and the brushing dust removing device is arranged, surfaces of unhulled rice grains can be brushed, dust adhering to the unhulled rice surfaces is removed by brushing, therefore, dust removing cleaning isconvenient, and the dust removing effect of the unhulled rice is good.

Owner:湖南尚源生物科技有限公司

Dustproof cleaning device for charging contact of charging pile

InactiveCN109677285AEasy to useEasy to clean dustCharging stationsDirt cleaningSupport planeEngineering

The invention discloses a dustproof cleaning device for a charging contact of a charging pile. The dustproof cleaning device comprises a support frame and a worktable, wherein the worktable is arranged at the bottom of the support frame; two bracket side plates are symmetrically arranged on the top of the worktable; the inner side of each of the bracket side plates is fixedly connected with an electric push rod arranged transversely; one end of an extension rod of the electric push rod is adhered to a rubber pad; a charging contact is arranged at one end of the electric push rod; a second cleaning brush is arranged at the bottom of the charging contact and is an insulated banister brush; the second cleaning brush is fixedly arranged on a second horizontal pipe; the second horizontal pipe is arranged between the two bracket side plates; one of the two bracket side plates is of a hollow structure, and a second motor case is arranged inside the bracket side plate; and two second suction inlets are symmetrically formed in the bottom of the second horizontal pipe. According to the arrangement of the first cleaning brush and the second cleaning brush, the upper and lower sides of the charging contact are conveniently subjected to cleaning dust collection, the manual cleaning labor intensity is reduced, and normal use of the charging contact is ensured.

Owner:安徽银点电子科技有限公司

A food processing machine with good dust-proof effect

ActiveCN109158178BImprove dustproof effectEasy to useFouling preventionCleaningGear wheelElectric machinery

The invention discloses a food processing machine with a good dustproof effect. The food processing machine comprises a food processing machine main body, wherein a first fixing base is fixedly connected with the right side of the bottom of the food processing machine main body. Due to adoption of the food processing machine main body, the first fixing base, a transmission tank, a first motor, a crushing tank, a discharge hole, a first rotating shaft, a crushing blade, a feeding tank, a baffle plate, a support rack, a second rotating shaft, a second motor, a barrel, caterpillar bands, a firstbrush, a cleaning tank, a second fixing base, a double-axis motor, a rotating disc, a first gear, a third rotating shaft, a second gear, fan blades, a third fixing base, a first sliding block and a first chute, the problems that dust can be easily introduced when materials are fed, a poor sanitary environment can be resulted, and dust can be easily dropped into a feeding hole after the machine isstopped since materials are fed into a conventional food processing machine from an opened feeding hopper, can be solved, and the food processing machine with the good dustproof effect has the advantages of being good in dustproof effect and is convenient for users to use.

Owner:天长市康盈米业有限公司

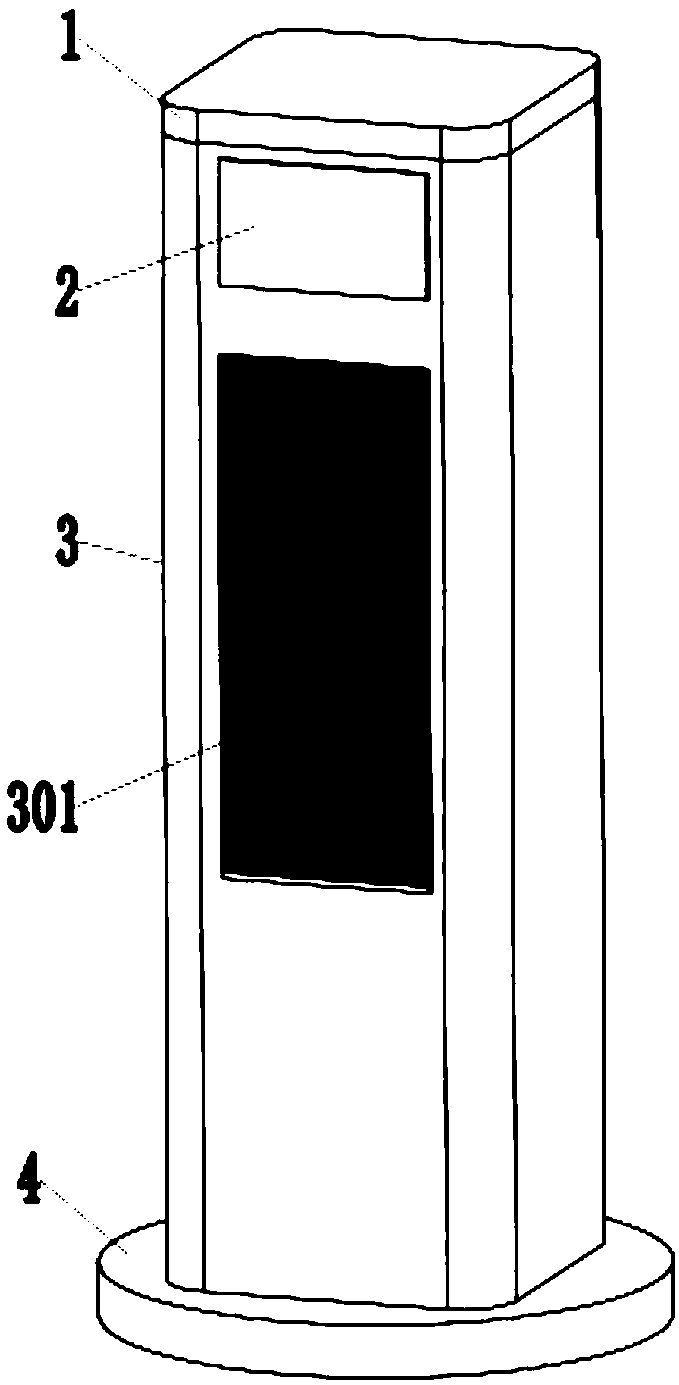

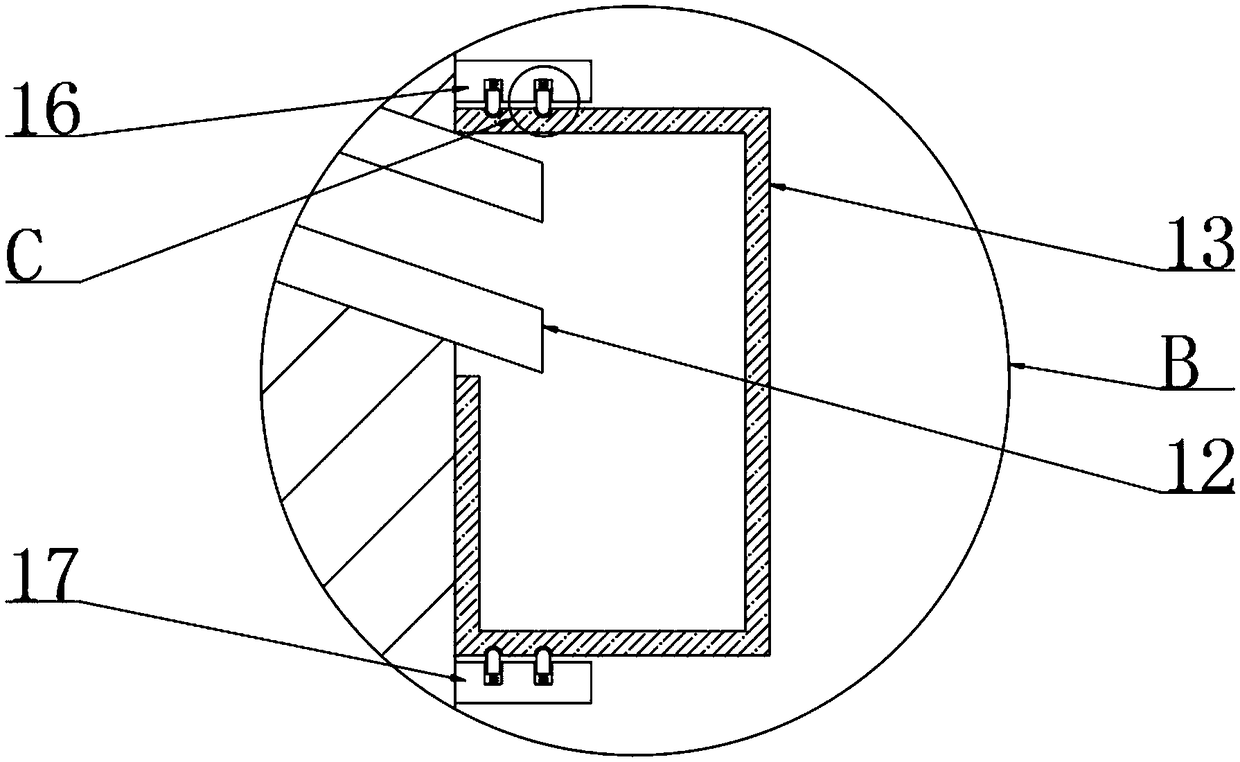

Indoor oxygenation and air purification integrated machine

PendingCN109340949AFixed firmlyEasy to installMechanical apparatusLighting and heating apparatusElectricityMagnet

The invention discloses an indoor oxygenation and air purification integrated machine. The indoor oxygenation and air purification integrated machine comprises a machine case and a base. An oxygen production module is arranged in the machine case and arranged at the lowest end in the machine case. A high-voltage power module is arranged above the oxygen production module. The upper portion of thehigh-voltage power module is connected with an emitting electrode and a dust collecting electrode. The emitting electrode is parallel to the dust collecting electrode. The lower end of the emitting electrode and the lower end of the dust collecting electrode are connected with the high-voltage power module. Magnets and switch inserting holes are formed in the upper end face of the machine case. Microswitches are arranged in the switch inserting holes. An upper cover is arranged at the upper end of the machine case and comprises an upper cover body and a cover plate. The cover plate is connected with the lower end of the upper cover body. Magnet attraction sheets and microswitch jacking protrusions are arranged on the lower end face of the cover plate. The magnet attraction sheets are attracted to the magnets, and the microswitch jacking protrusions are matched with the switch inserting holes. A control module is arranged at the upper end of the side wall of the machine case and electrically connected with the high-voltage power module and the oxygen production module.

Owner:临清市华东机械制造有限公司

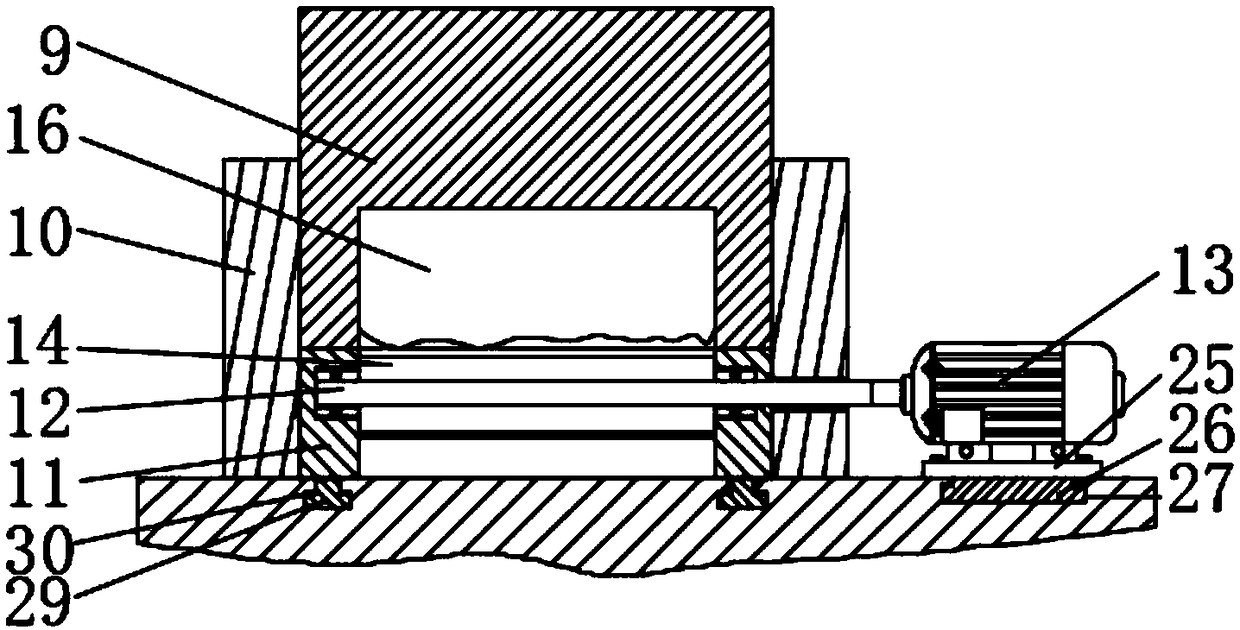

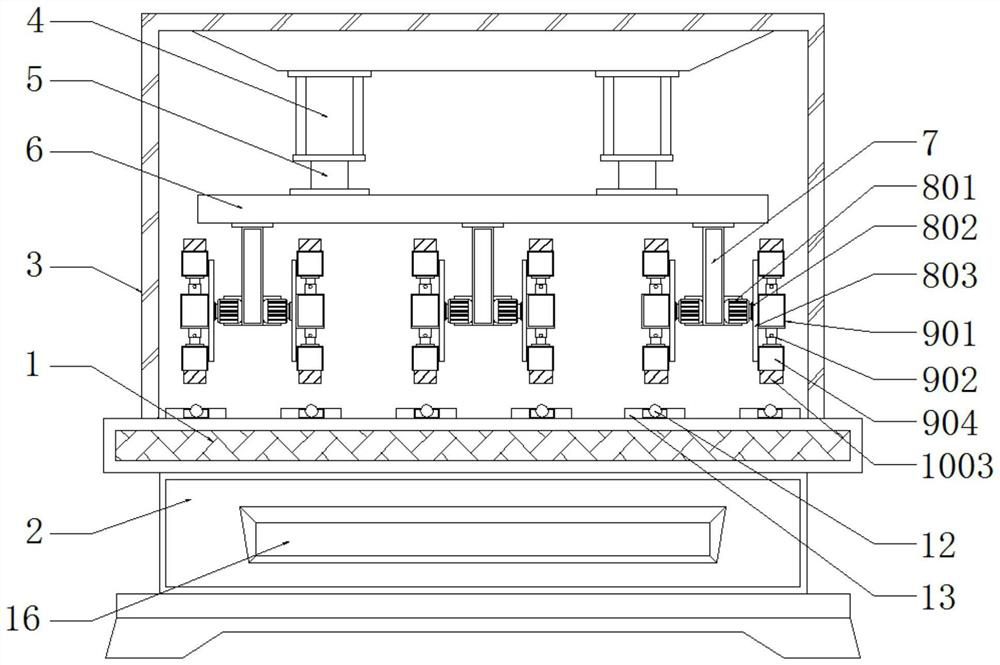

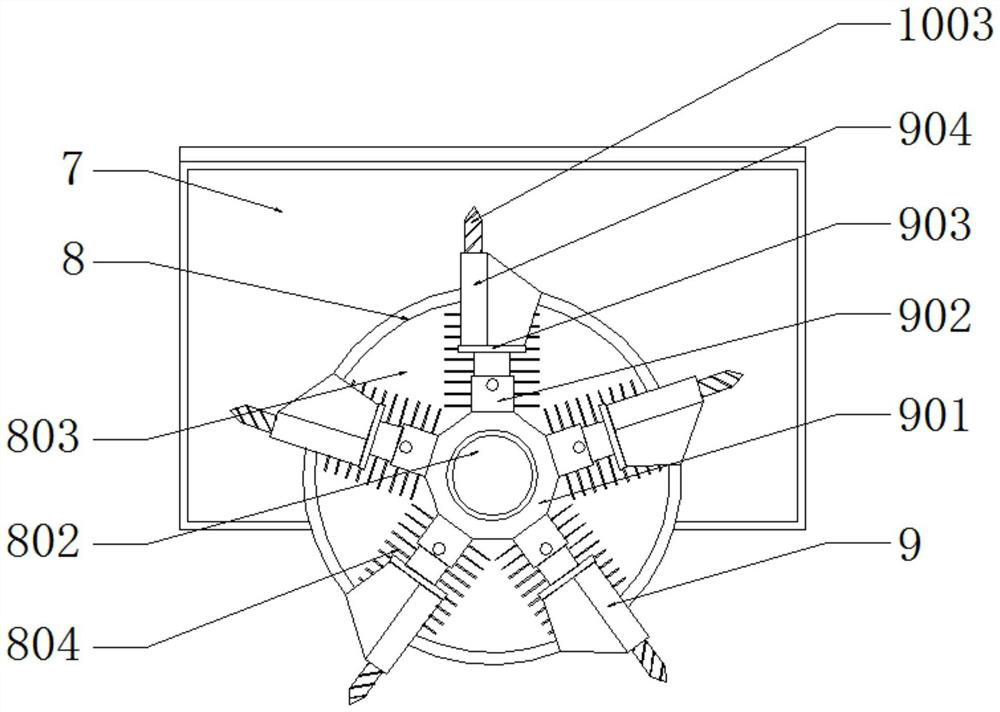

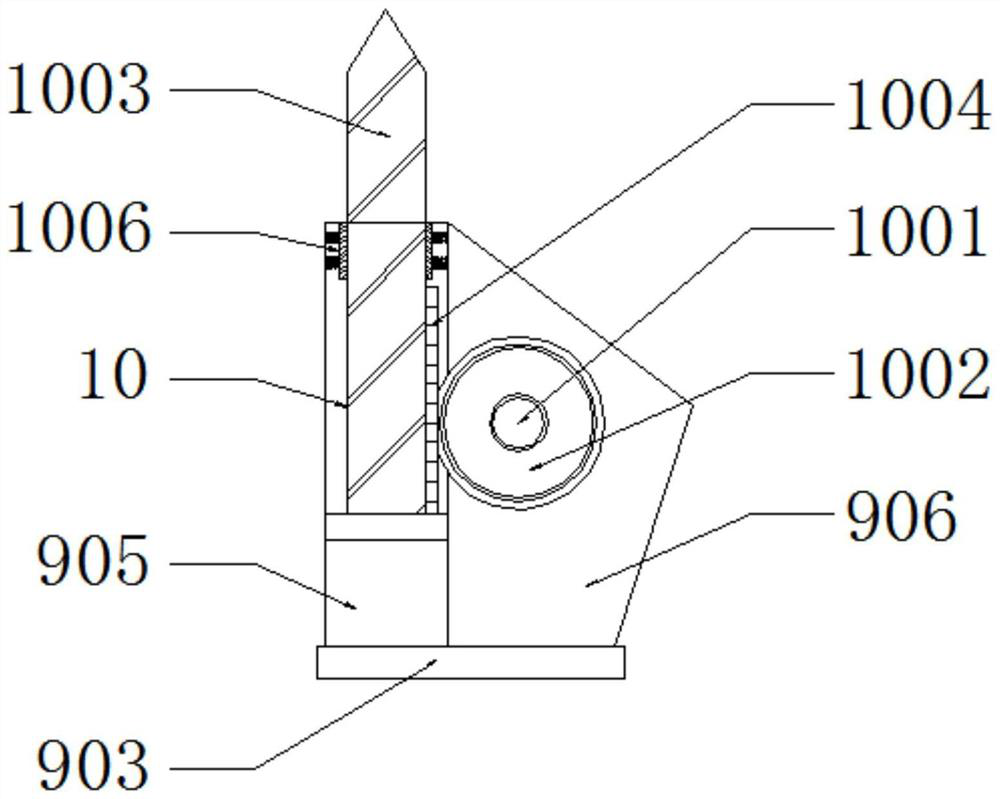

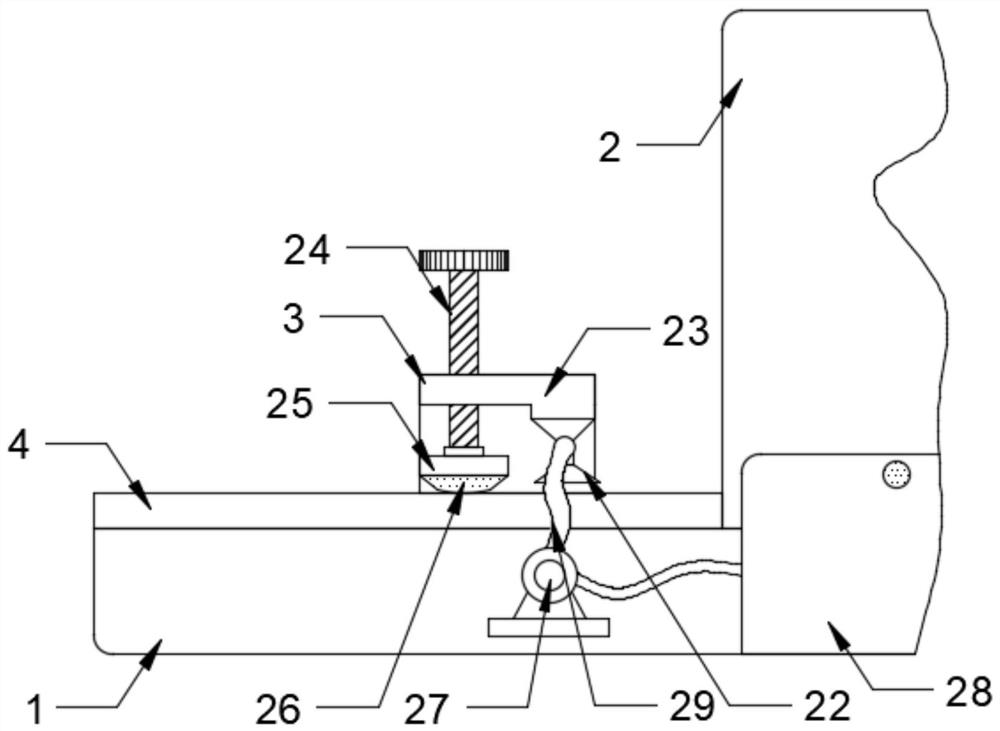

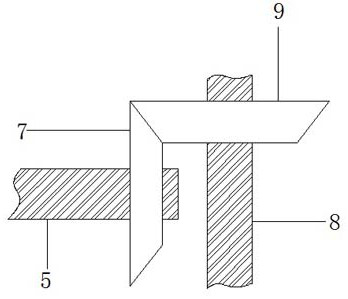

Fixed-distance adjusting granulator for PBT (polybutylene terephthalate) production

PendingCN114274200ARealize the function of fixed distance adjustmentSimple and fast operationMetal working apparatusEngineeringPolybutylene terephthalate

The invention discloses a fixed-distance adjusting granulator for PBT production, and relates to the technical field of PBT production, the fixed-distance adjusting granulator comprises a workbench, a telescopic distance adjusting assembly and a granulating assembly, a machine frame is fixed below the workbench, an upper frame body is fixed above the workbench, an air cylinder is installed below the inner side of the upper frame body, a piston rod is arranged on the lower side of the air cylinder, and the telescopic distance adjusting assembly is connected with the piston rod. A lifting plate is fixed to the lower portion of the piston rod, and a fixing plate is installed below the lifting plate. According to the fixed-distance adjusting granulator for PBT production, the length of the granulating assembly is adjusted through the electric telescopic rod, the distance between the granulating assembly and a PBT plastic strip can be adjusted, granulating operation is conducted based on different distances and lengths, the granulating effect of different lengths can be achieved in cooperation with constant-speed feeding of the PBT plastic strip, and therefore the fixed-distance adjusting effect can be achieved; and in addition, the pelletizing operation can be carried out in the feeding process of the PBT plastic strips, a plurality of cutters do not need to be transversely arranged, fixed-distance adjustment is achieved by adjusting the distance of the cutters through frequent sliding, and the operation is relatively simple and efficient.

Owner:南通瑞隆新材料有限公司

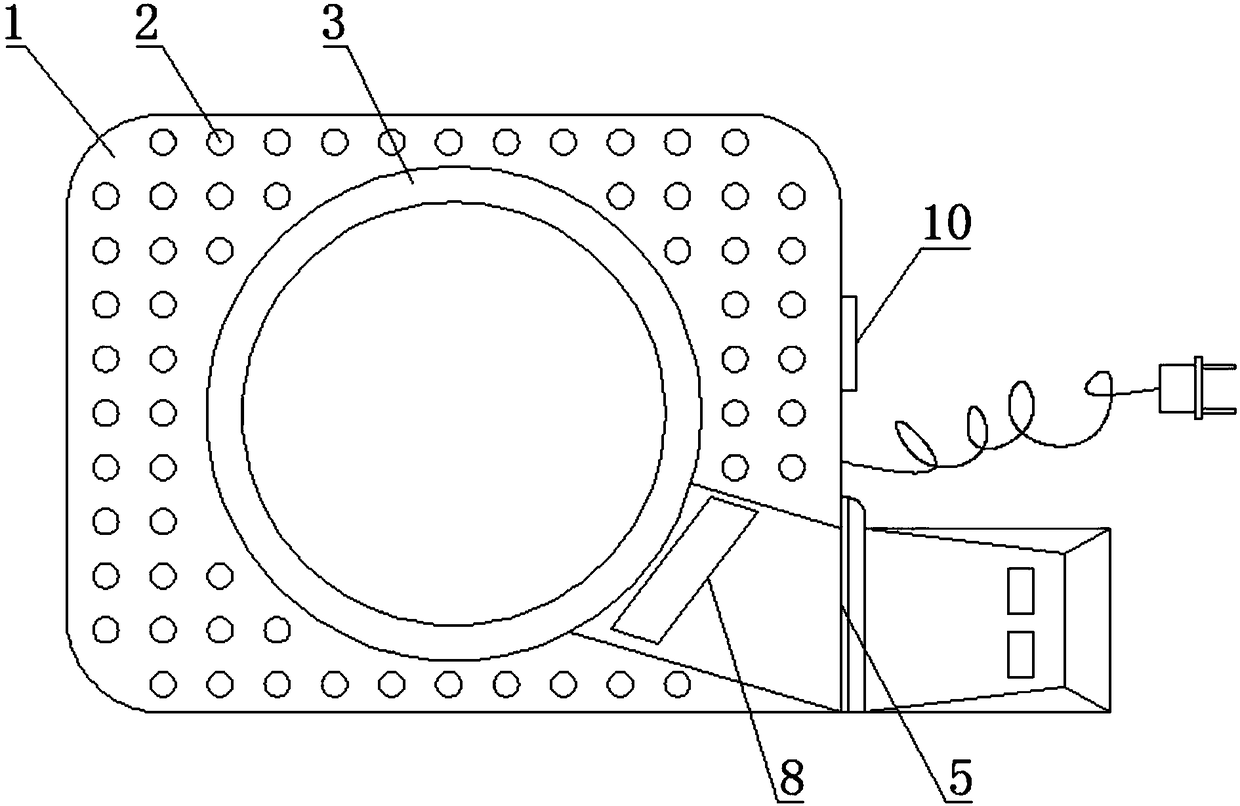

A money counter for easy dust removal

InactiveCN109034348AReasonable structureExtended service lifeCounting objects on conveyorsEngineering

Owner:PINGYANG RANPENG ELECTRONICS MACHINERY

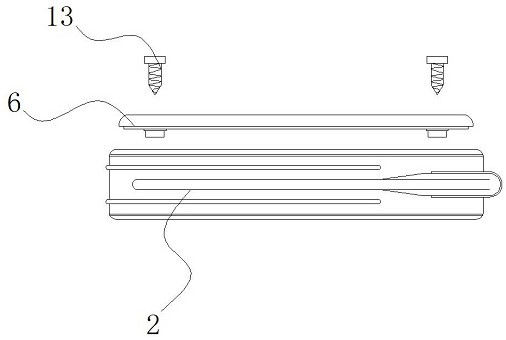

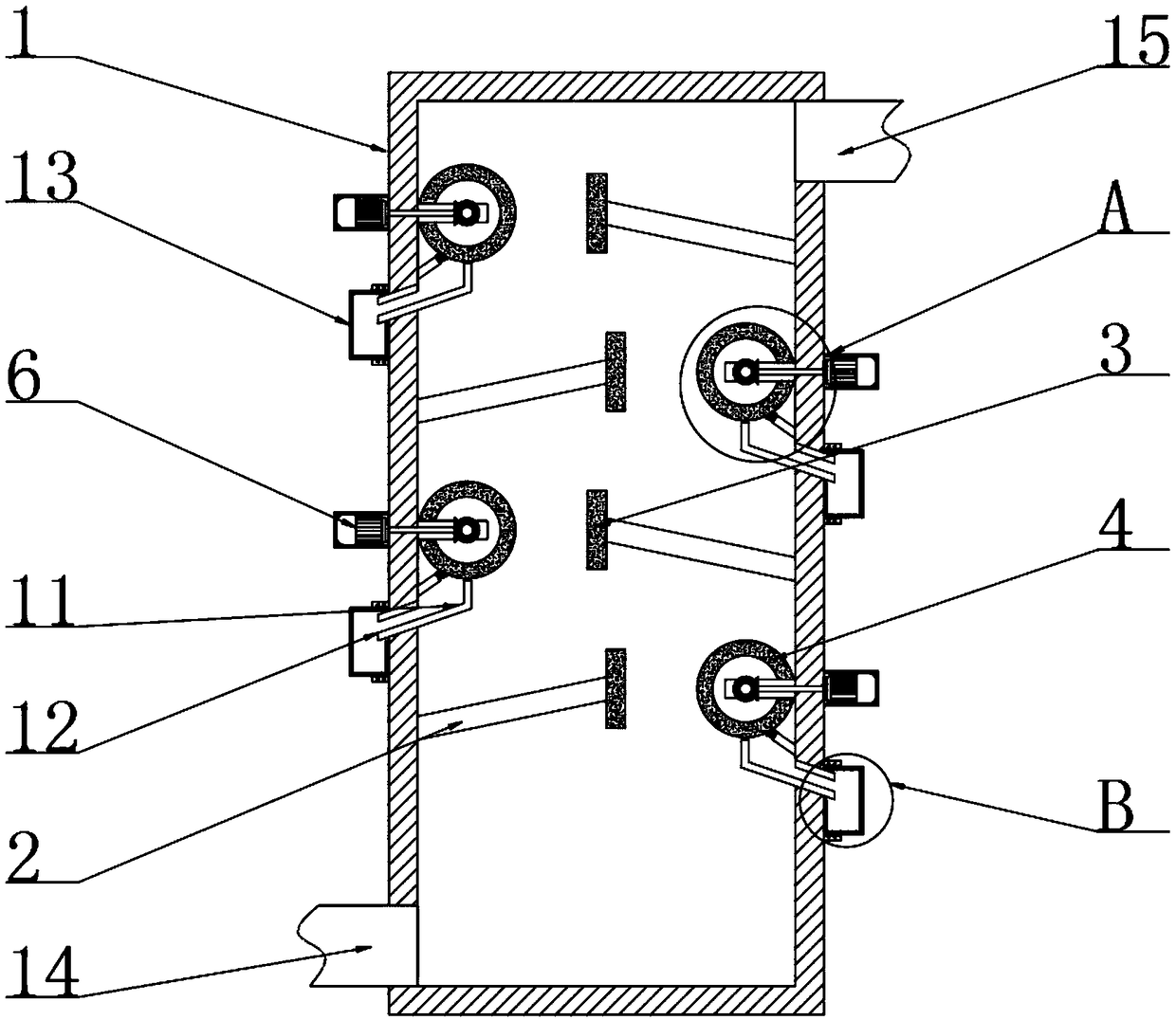

Adhesive tape sticking device applied to SMT steel sheet

ActiveCN111642074AEasy to clean dustGuaranteed accuracyPrinted circuit assemblingComposite materialStructural engineering

The invention discloses an adhesive tape sticking device applied to an SMT steel sheet. The device comprises a base and a steel sheet body, wherein a conveying belt is arranged at the top of the base,and the steel sheet body is arranged on the surface of the conveying belt. The device further comprises an adhesive tape sticking mechanism and a dust collection mechanism, wherein the adhesive tapesticking mechanism and the dust collection mechanism are respectively arranged at two ends of the top of the base; fixing plates are symmetrically fixed to the end, which is located on the adhesive tape sticking mechanism, of the top of the base; communicating holes in the horizontal direction are formed in the two ends of the fixing plates; and a first threaded rod is connected into the communicating hole in a sliding manner. According to the adhesive tape sticking device for the SMT steel sheet, the position of each limiting plate can be adjusted by comparing scale marks on the base according to the width of the steel sheet body, the steel sheet body is limited between the two limiting plates to slide in the transportation process, the accuracy of the adhesive tape sticking position is guaranteed, an adhesive tape roll is convenient to disassemble and assemble through the arrangement of an adjusting plate, a transverse plate, a cross rod, a fixing block and a lead screw, the steel sheet before adhesive tape sticking can be conveniently dedusted and cleaned through the dust collection mechanism, the adhesive tape can be better attached to the steel sheet, and the adhesive tape sticking quality is guaranteed.

Owner:JIAN COLLEGE

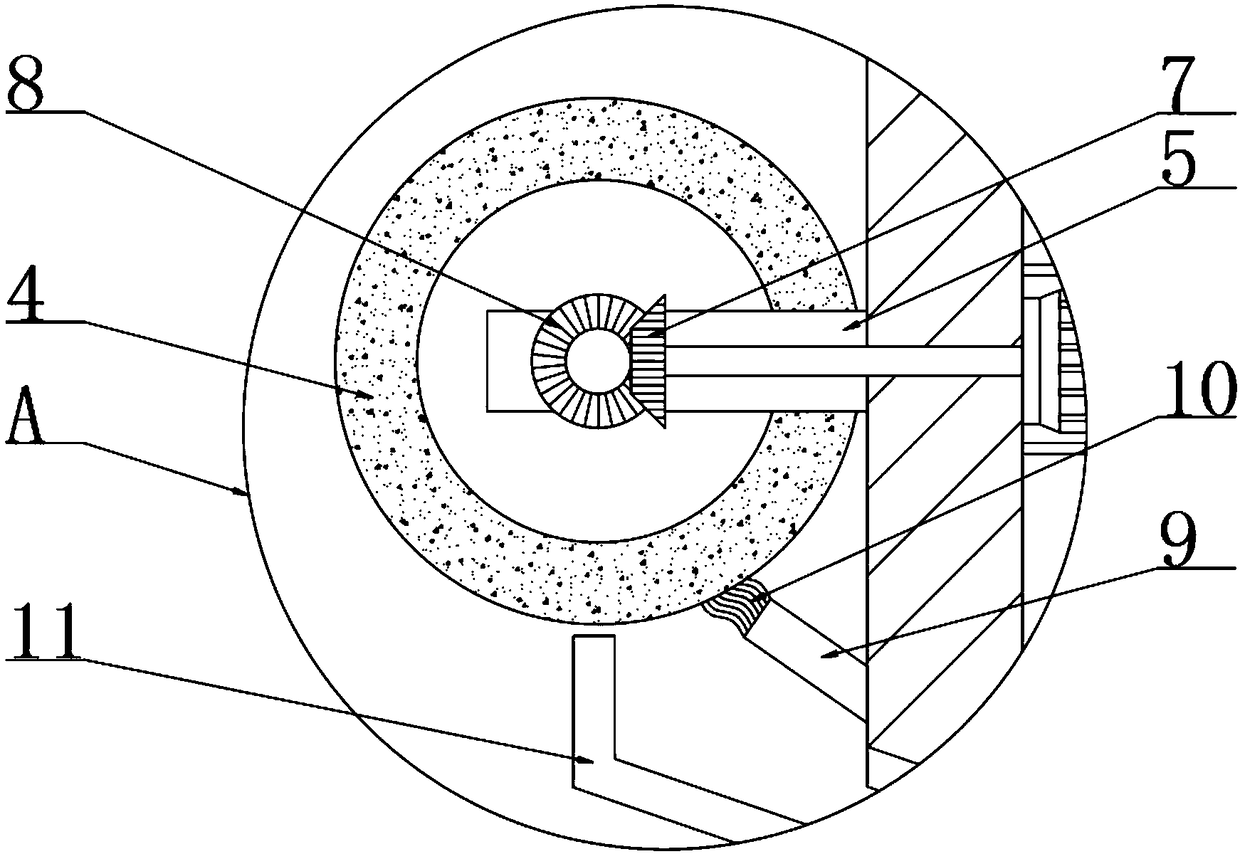

Environment-friendly dust-collection mechanical equipment

InactiveCN108889449AEasy to clean dustExtended stayExternal electric electrostatic seperatorElectrodes cleaningAnodeBevel gear

The invention discloses environment-friendly dust-collection mechanical equipment. The equipment comprises a tank body, wherein a baffle is arranged on one side of the inner wall of the tank body, a cathode discharging board is arranged at one end of the baffle, and an anode discharging roll is arranged on one side of the cathode discharging board; a support frame is arranged on the inner wall ofthe tank body, two ends of a rotating shaft of the anode discharging roll are rotatably connected with the support frame, a motor is arranged on one side of the outer wall of the tank body, a first bevel gear is arranged at one end of a transmission shaft of the motor, and a second bevel gear is arranged at one end of a rotating shaft of the anode discharging roll and is meshed with the first bevel gear; a brushing rod is arranged at the bottom of the support frame, and a cleaning brush is arranged at the top end of the brushing rod and is in contact connection with the surface of the anode discharging roll. According to the technical scheme, the anode discharging board is changed into the anode discharging roll, the anode discharging roll is driven to rotate by the motor, and the cleaningbrush is arranged at the bottom of the anode discharging roll and is used for collecting and collecting the dust on the surface of the anode discharging roll.

Owner:肇庆市天地人科技有限公司

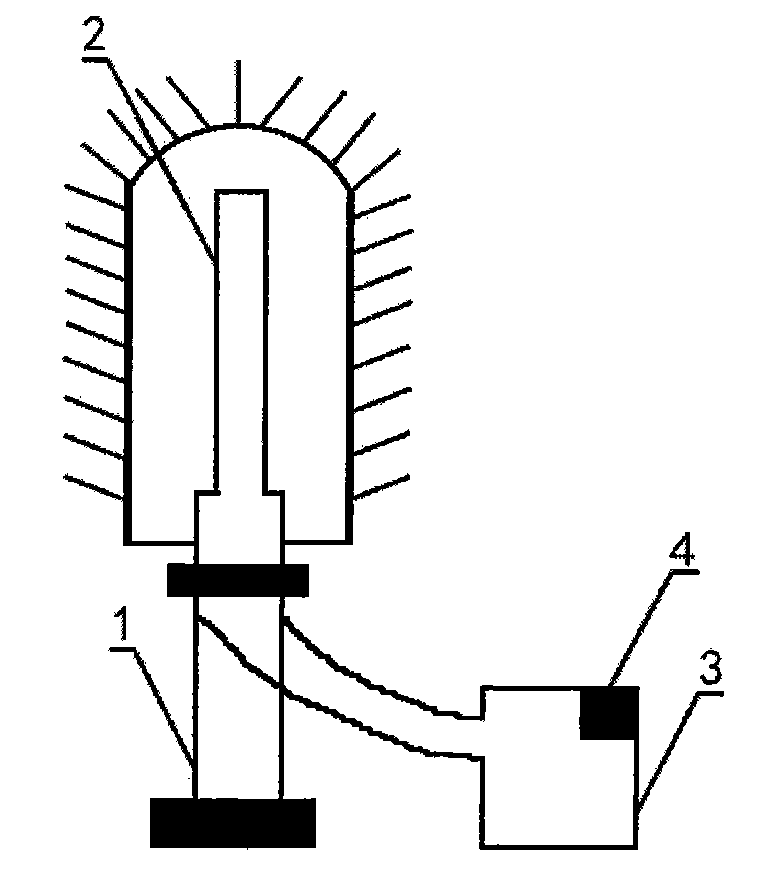

Electric dust collection duster

The invention discloses an electric dust collection duster. A duster body [1] is provided with a dust collection pipeline [2] which is connected with a negative pressure air source. The front end of the dust collection pipeline [2] is flush to the duster body. The dust collection pipeline [2] is provided with dense dust collection holes, and when the duster body moves on an object, the produced dust is adsorbed by the dust collection pipeline. A dust collection basket [3] is arranged at the tail end of a soft pipe of the dust collection pipeline to collect the dust. The dust collection basket [3] is internally provided with an induction device [4] which sends out reminding information when the basket is full of dust, wherein reminding information modes are generally sound or LED light display. The duster body is generally made of feathers and is suitable for cleaning automobiles and high-end materials. The dust can be automatically adsorbed when the duster is used for carrying out cleaning, and convenience is brought to dust collection.

Owner:NINGXIA KANGCHENG ELECTRICAL & MECHANICAL PROD DESIGN CO LTD

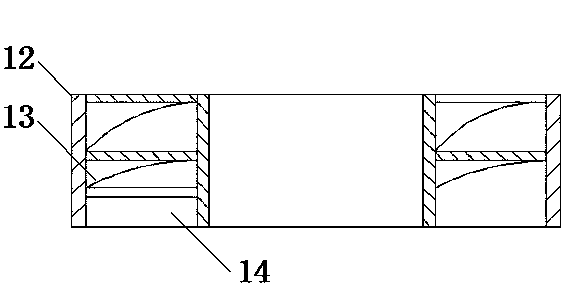

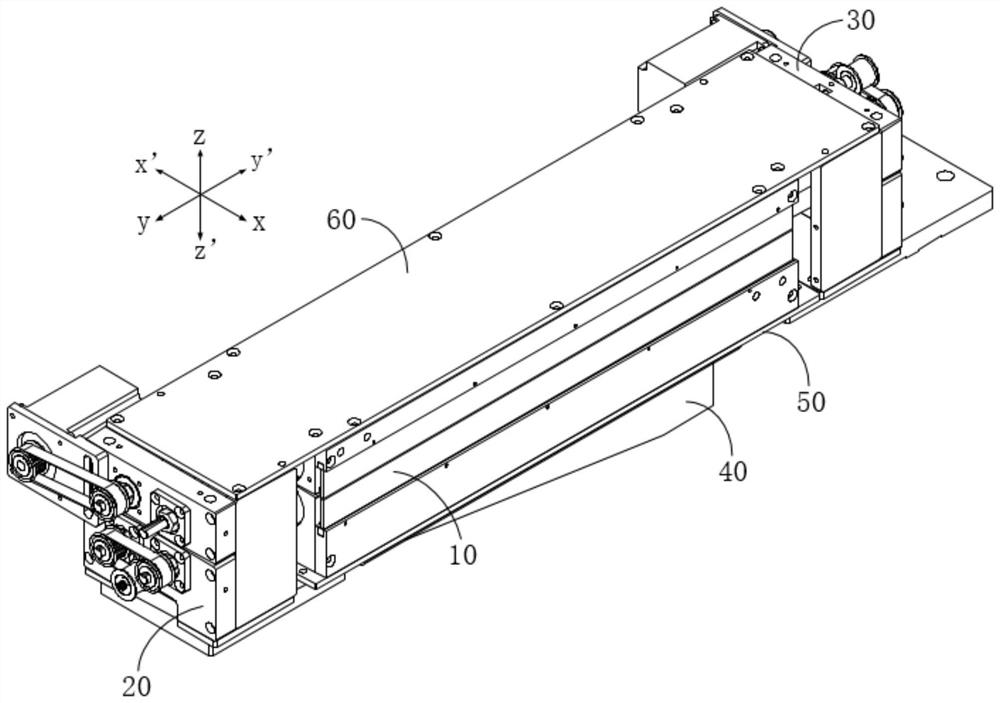

Cleaning structure and laser processing equipment

InactiveCN113289945AAchieve double-sided cleaningEasy to assembleCleaning using toolsLaser beam welding apparatusLaser processingAssembly line

The invention relates to a cleaning structure and laser processing equipment. The cleaning structure comprises a rolling brush mechanism, a front end cover mechanism and a rear end cover mechanism. The rolling brush mechanism comprises a first rolling brush set and a second rolling brush set, the first rolling brush set and the second rolling brush set are oppositely arranged in a spaced manner in the first direction, and a first cleaning gap is formed between the first rolling brush set and the second rolling brush set. The front end cover mechanism is arranged at the first end, in the second direction, of the rolling brush mechanism, and the front end cover mechanism comprises a first driving set used for driving one of the first rolling brush set and the second rolling brush set to rotate. The rear end cover mechanism is arranged at the second end, in the second direction, of the rolling brush mechanism, and the rear end cover mechanism comprises a second driving set used for driving the other one of the first rolling brush set and the second rolling brush set to rotate. The cleaning structure provided by the invention can be directly arranged in a conveying mechanism used for conveying plates in a laser processing assembly line, so that the plates are conveyed to the position between the two rolling brush sets through the conveying mechanism, the assembly is convenient to carry out, and no extra floor space is needed.

Owner:HANS LASER TECH IND GRP CO LTD

Test device for permeability of waterproof material

The invention provides a testing device for permeability of a waterproof material. The device comprises a protective casing I, a jet pipe, an electric heating plate, a gas transmission pipe, an air pump, a protective casing II, a screw, a bearing block, a metal connecting rod, a rotating shaft and a cleaning brush, wherein the jet pipe and the electric heating plate are mounted in the protective casing I, the electric heating plate is arranged on the front side of the jet pipe, an air pipe is assembled at the right end of a casing, the left end of the air pipe penetrates the casing and is connected with the jet pipe, and the air pump is arranged at the rear end of the jet pipe. By means of the design, a material plate is convenient to dry, the screw and the bearing block are arranged in the protective casing II, the bearing block is assembled on the annular side surface of the screw, the metal connecting rod is arranged at the rear end of the protective casing II, the front end of themetal connecting rod penetrates the protective casing II and is connected with the bearing block, the rotating shaft is arranged in the metal connecting rod, and the cleaning brush is assembled on theannular side surface of the rotating shaft. Therefore, a glass window is convenient to clean. The device is convenient to use and operate, and facilitates drying of the material plate, cleaning and dust removal.

Owner:河南蓝翎环科防水材料有限公司

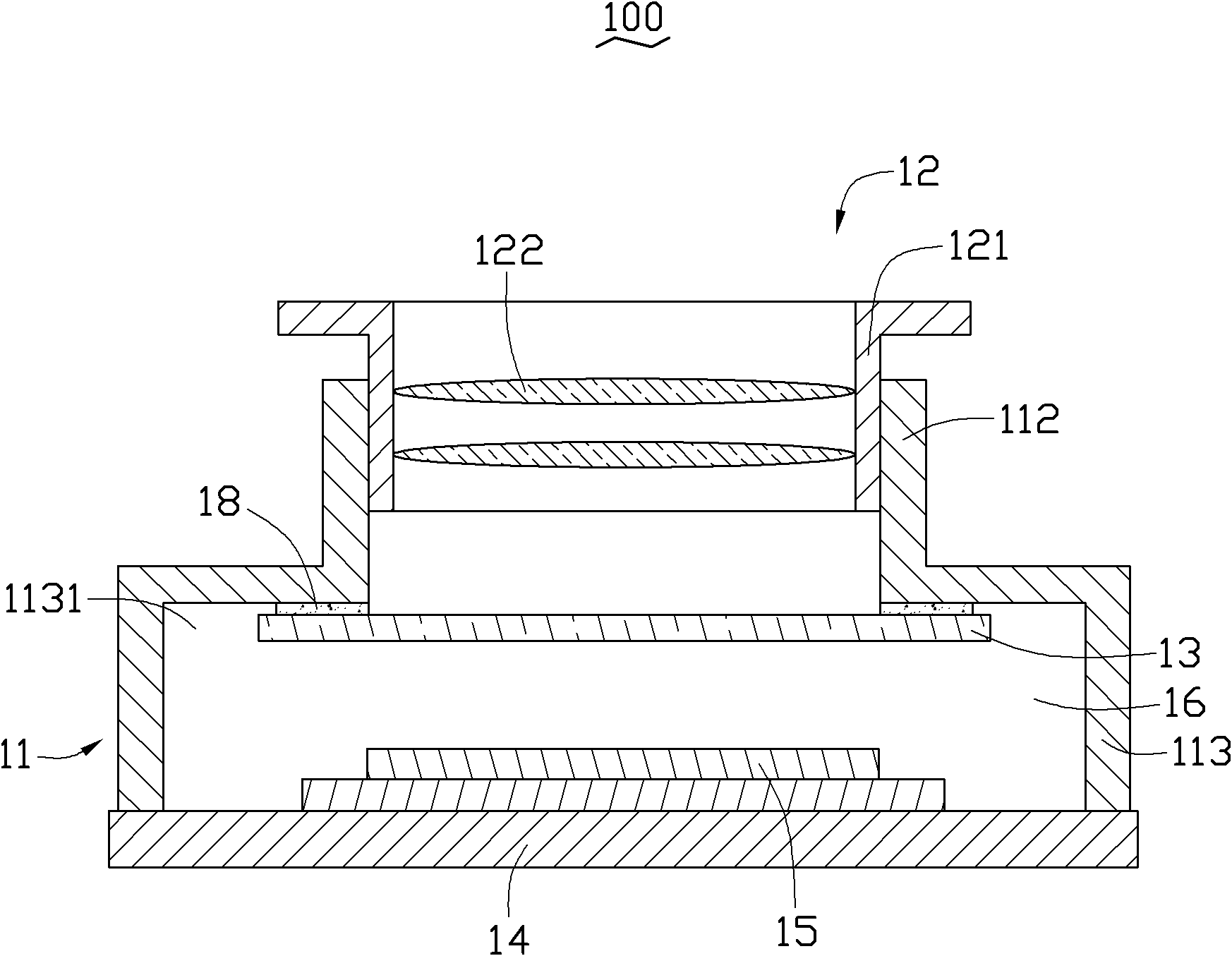

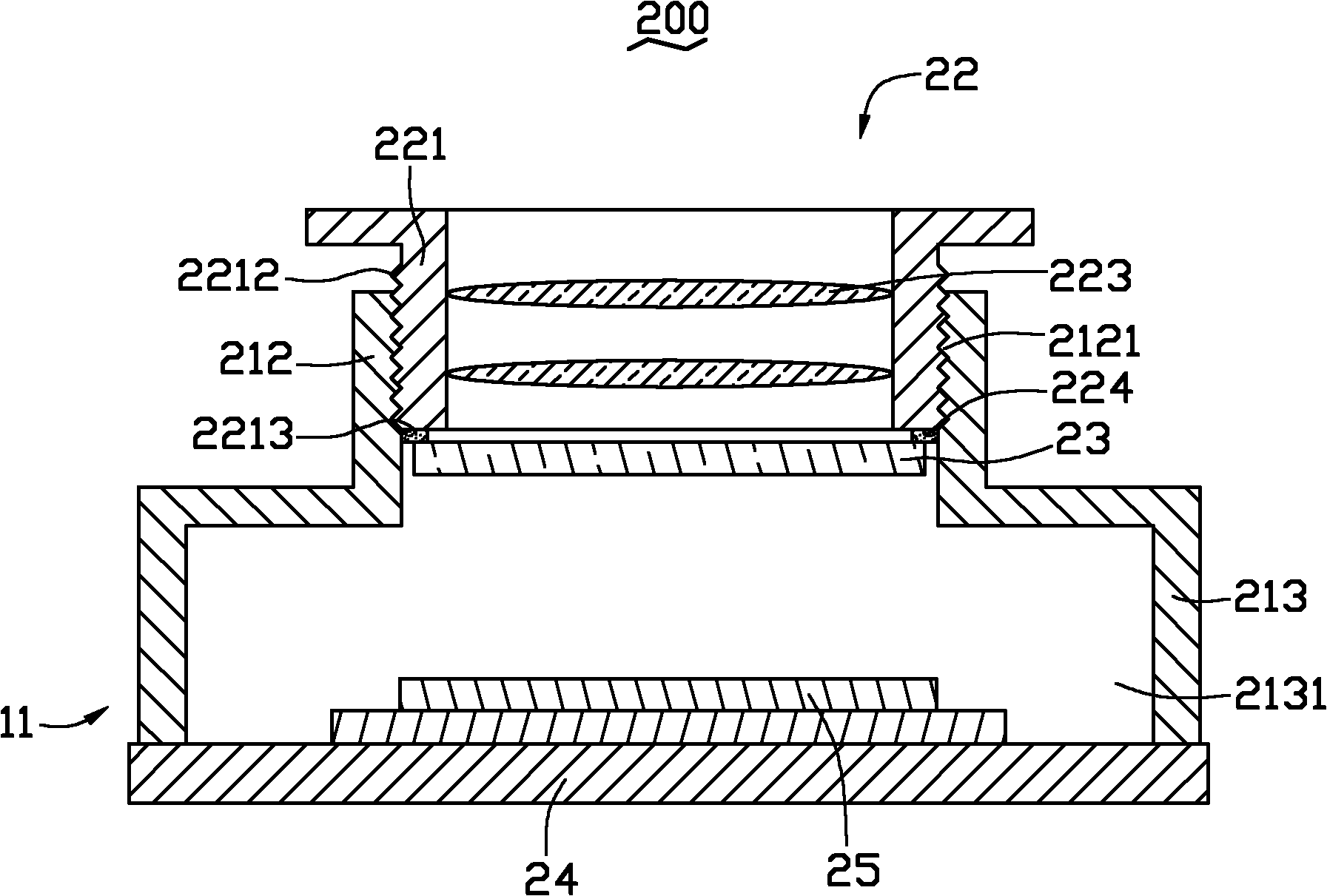

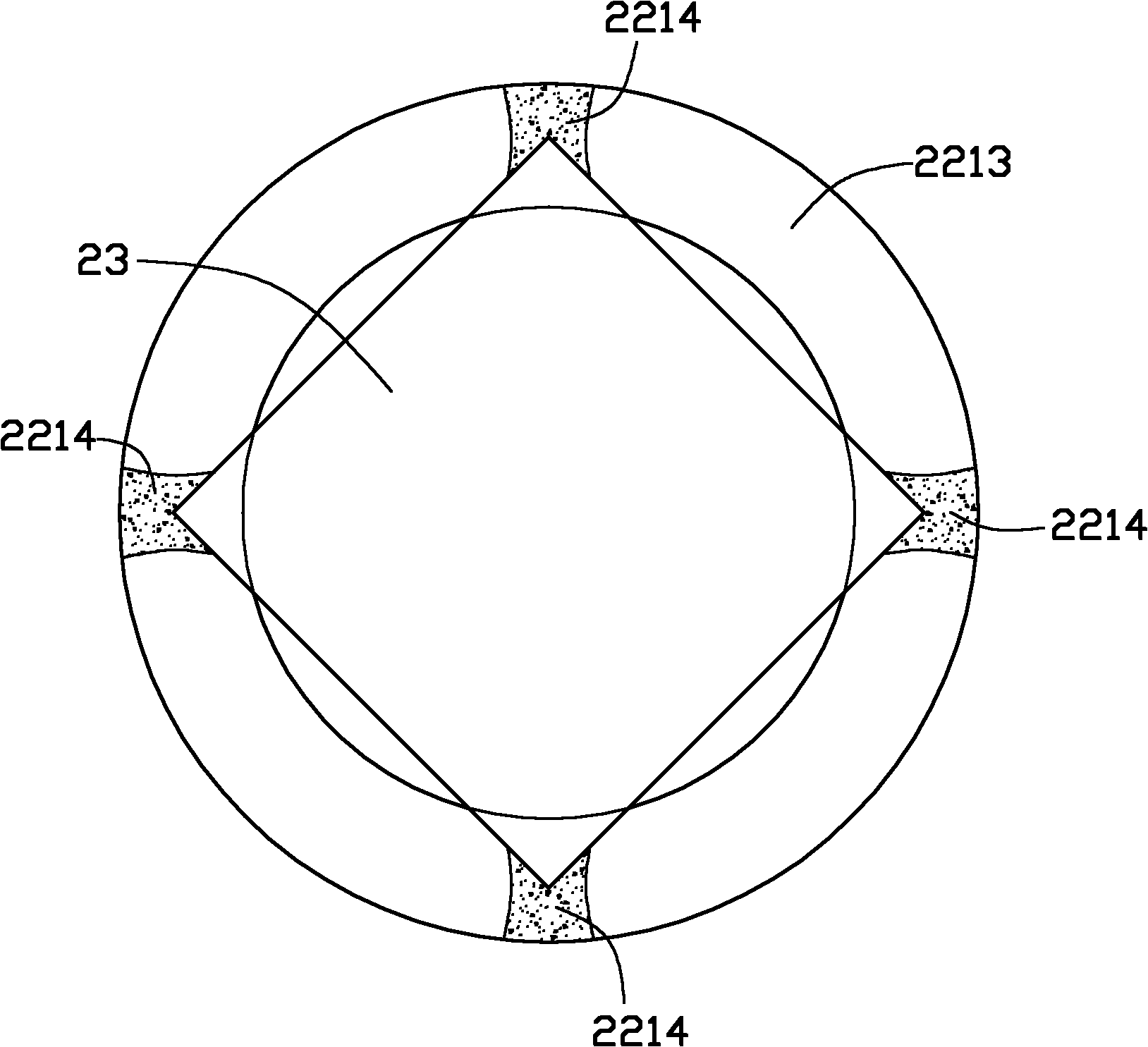

Imaging module and method for assembling the same

InactiveCN102262275BIncreased sensitivityEasy to clean dustTelevision system detailsColor television detailsElectricityCamera lens

An imaging module comprises a pedestal, a lens module, an optical filter, a base plate connected to the pedestal, and an image sensor which is electrically connected with the substrate. The pedestal comprises a view finding barrel and a base inside which a receiving portion is formed, wherein the image sensor is accommodated in the receiving portion. The lens module is fastened into the view finding barrel and comprises a lens barrel and at least one lens arranged in the lens barrel. The lens module is provided with an adhesive rubber mass. The optical filter is bonded to the lens module through the adhesive rubber mass. Besides, incident light orderly passes through the lens module and the optical filter to arrive in the image sensor. The imaging module is easy to manufacture and high in yield. The invention also provides a method for assembling the imaging module.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

A dust removal device for electronic products

ActiveCN110947661BPrevent slippingEasy to fixCleaning using toolsElectric machineryIndustrial engineering

The invention provides an electronic product cleaning device, which relates to the technical field of electronic equipment, including: a support plate, a positioning structure, a support frame, a pushing structure, a cleaning structure and a sweeping structure. Under the action of the rod, the electronic product is clamped and positioned. At the same time, the limit rod that does not slide is set around to limit the position of the electronic product and avoid the slippage of the electronic product when cleaning the dust. It can be adapted to various electronic products and play a very important role at the same time. Good positioning and fixing effect is convenient for dust cleaning operation. By setting the push structure, under the cooperation of the push motor and the push cylinder, the positions of the dust removal structure and the sweeping structure are adjusted to the top side of the electronic product, and the push type dust removal operation can be realized. , through the combination of the cleaning structure and the sweeping structure, the electronic products can be cleaned quickly and efficiently, and the cleaning environment can be guaranteed to be clean, the cleaning efficiency can be improved, and the electronic products are not damaged.

Owner:西安微城信息科技有限公司

Cleaning and dust removing device for electrical maintenance

InactiveCN112157009AGood cleaning and dust removal effectImprove dust removal efficiencyDirt cleaningCleaning using toolsDust controlEnvironmental engineering

The invention discloses a cleaning and dust removing device for electrical maintenance. The cleaning and dust removing device comprises a base, wherein universal wheels are installed at the four corners of the bottom of the base, a push handle is welded to the side wall of the base, a dust removing box is installed on the upper part of the base, and a servo motor is fixedly installed on the outerwall of the upper portion of one side of the dust removing box through bolts; and an output shaft of the servo motor is connected with a first lead screw through a coupler, the first lead screw is sleeved with a first threaded sleeve, the first lead screw is connected with a driving bevel gear through a bearing, and a second lead screw is inserted into the dust removal box in a vertical direction.Through cooperative use of the servo motor, the first lead screw, the second lead screw and a brush strip, the cleaning and dust removing effects are good, time and labor are saved, the interior andthe exterior of electrical equipment can be subjected to dust removal at the same time, the dust removing efficiency is high, people can conveniently perform cleaning and dust removing on the electrical equipment of different heights through a hydraulic supporting rod, and an air inlet cover can prevent dust from flying everywhere in a cleaning and dust removing process.

Owner:湖南帝奥电梯工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com