Multi-stage unhulled rice dust removing device for processing rice

A dust removal device and rice processing technology, applied in the directions of packaging, loading/unloading, transportation and packaging, etc., can solve the problems of difficult dust removal, poor dispersion, and heavy physical load of workers, and achieve good dust removal effect, easy wind dust removal, and convenient dust removal. Dust cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

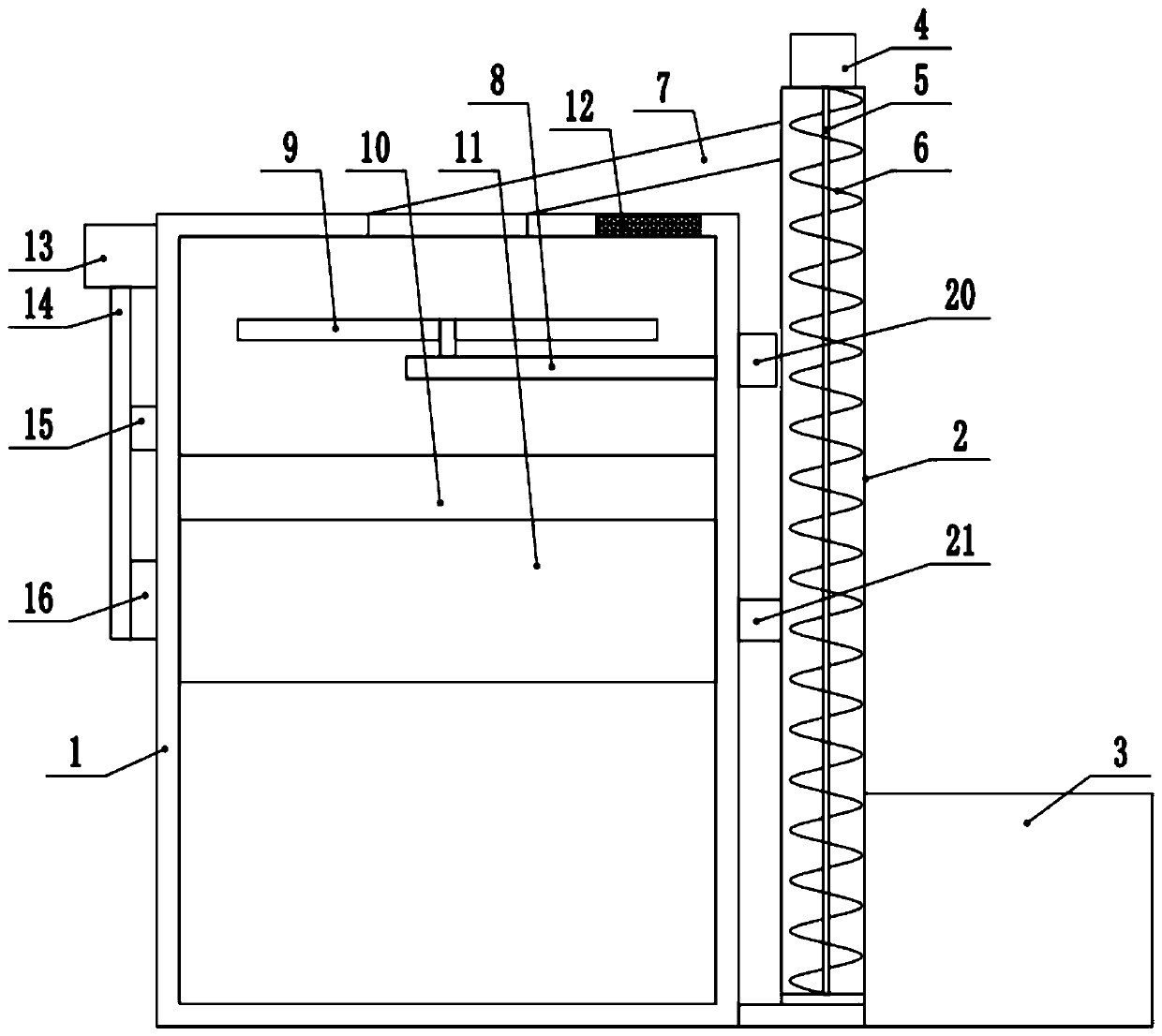

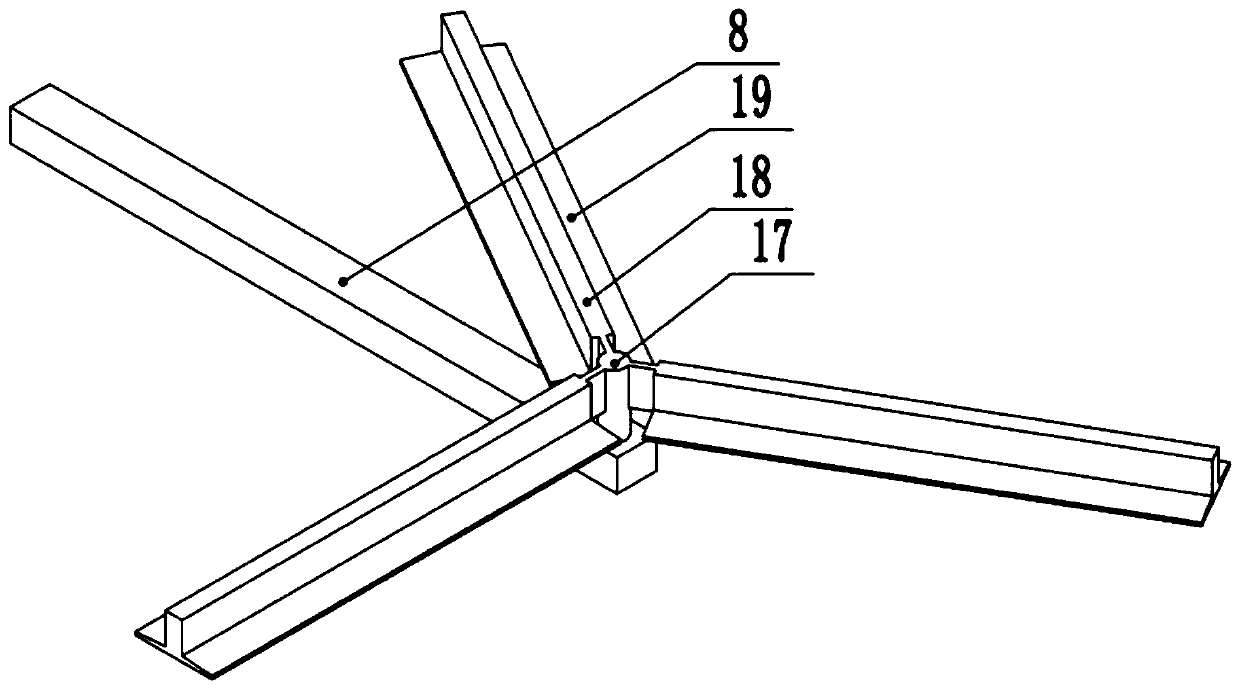

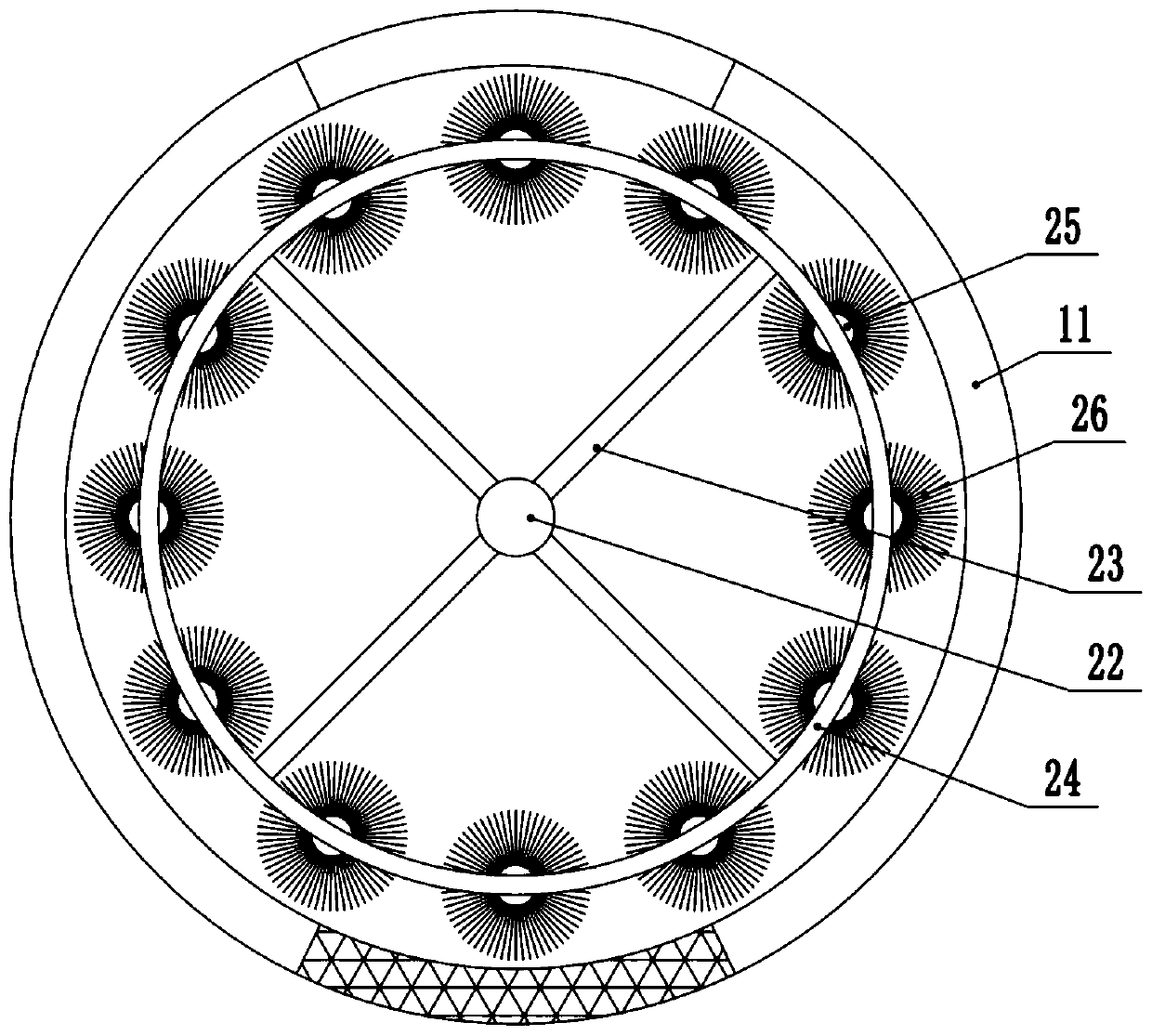

[0022] see Figure 1-3 , a kind of multi-stage paddy dedusting device for rice processing, comprising a dust removal box 1, one side of the dust removal box 1 is fixedly provided with a feeding lifting mechanism, and the top of the dust removal box 1 is provided with a first fixed rod 8, the first fixed rod 8 The rod 8 is fixedly connected with the dust removal box 1, and the end of the first fixed rod 8 is provided with a dispersion device 9, and a brushing dust removal device is provided below the dispersion device 9, and the brushing dust removal device includes an outer fixed cylinder 11, and the outer fixed cylinder 11 is coaxially rotated and connected to the second rotating rod 22, and both ends of the outer fixed cylinder 11 are provided with fixing rings 24, and the connecting rod 23 is fixedly connected between the fixing ring 24 and the second rotating rod 22, and between the two fixing rings 24 Fixedly connect a plurality of second fixed rods 25, the outside of the...

Embodiment 2

[0025] see Figure 1-3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the top and the bottom of the outer fixing cylinder 11 are respectively provided with a feed inlet and a discharge outlet, and the top of the feed inlet is fixed; The cover 10 is fixedly connected with the buffer net in the discharge port.

[0026] The present invention can mechanically and automatically feed the rice by setting the feeding lifting mechanism, and can disperse the rice being fed by setting the dispersing device 9, so as to facilitate wind dust removal, and the surface of the rice particles can be brushed by setting the brushing dust removal device , to brush off the dust adhered to the surface of rice, so that it is easy to remove dust and clean, and the dust removal effect on rice is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com