Imaging module and method for assembling the same

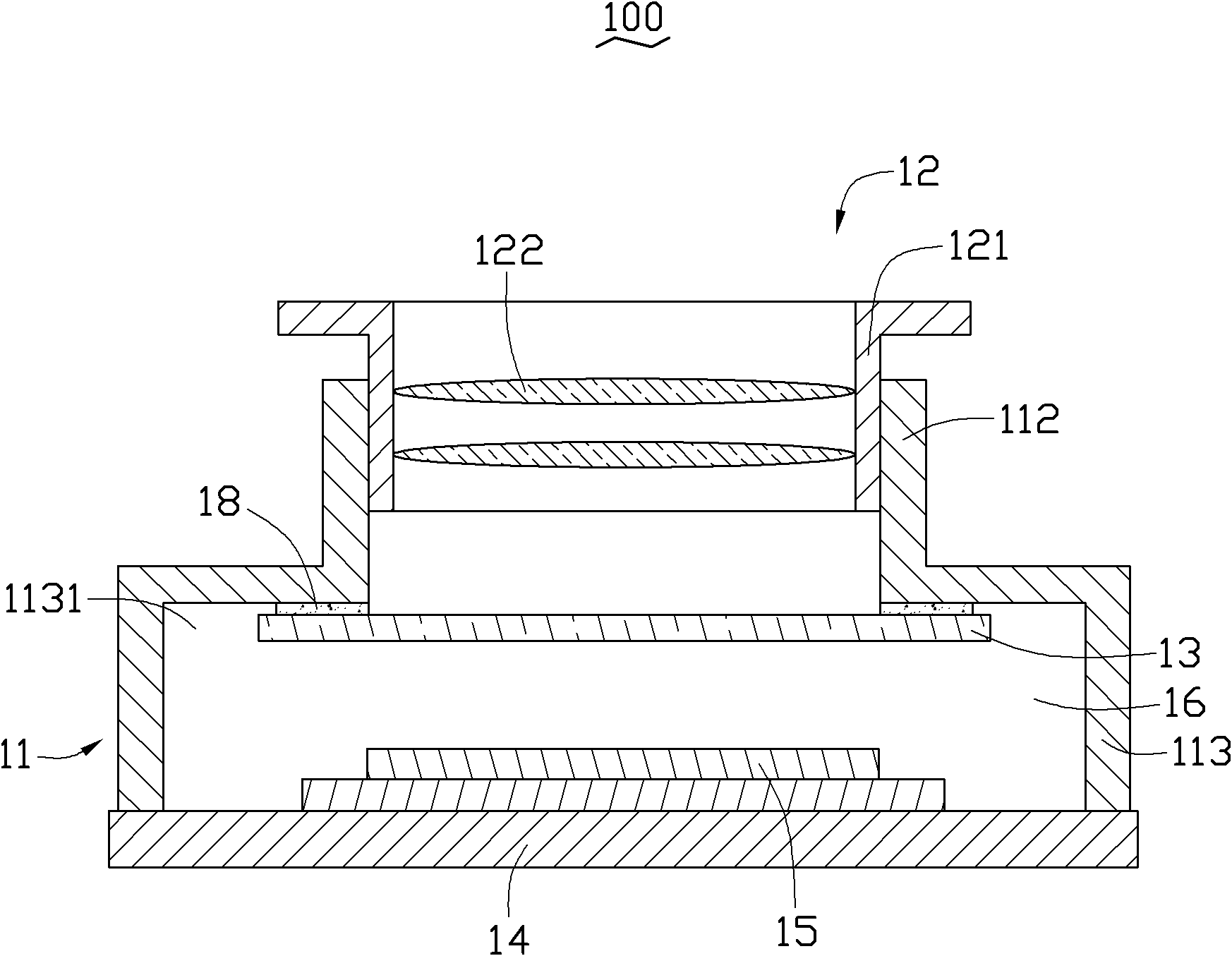

A technology of imaging module and assembly method, applied in installation, image communication, television, etc., capable of solving problems such as generation of fine dust, low yield rate of imaging module 100, and reduction of imaging quality of image sensor 15

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

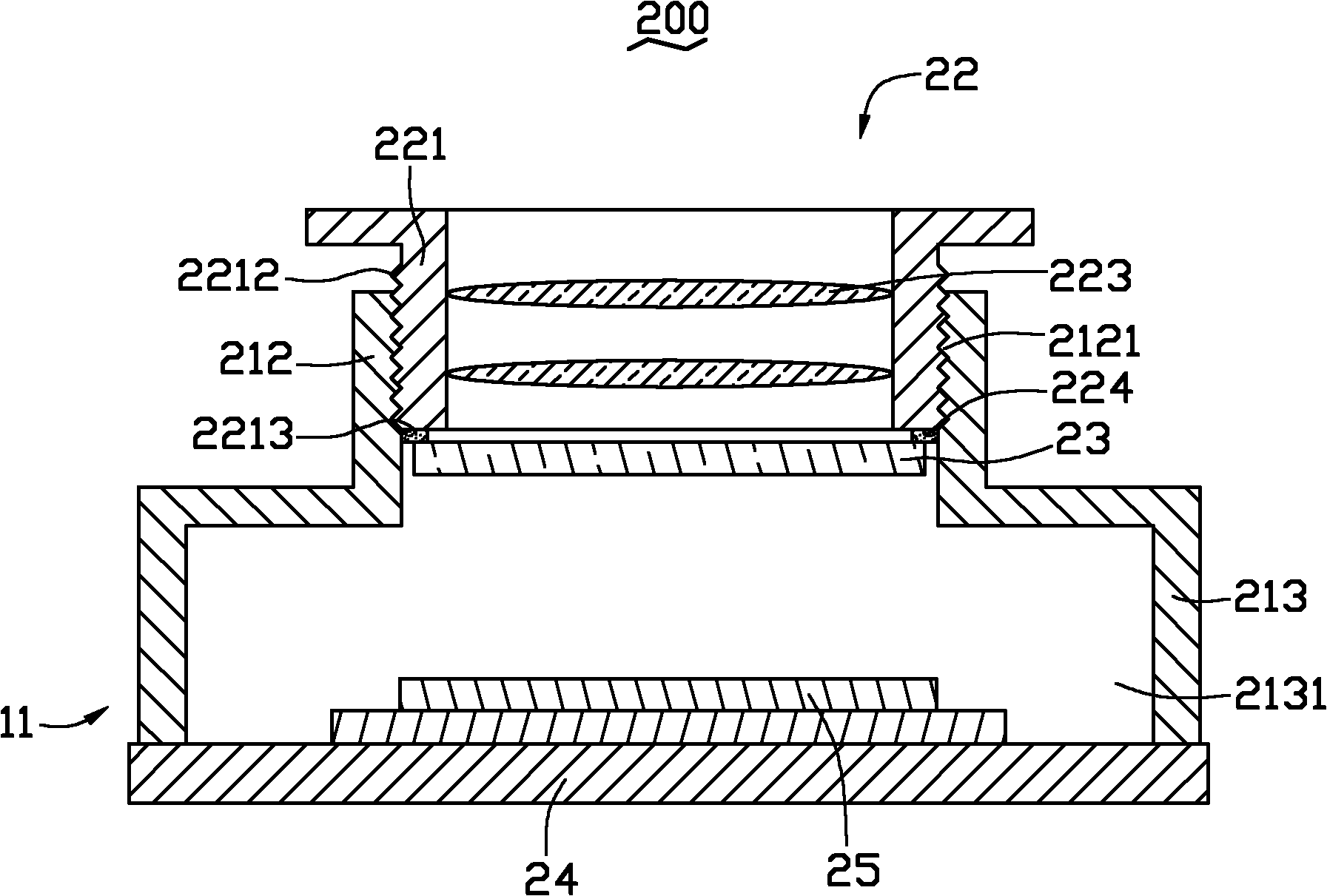

[0018] see figure 2 The imaging module 200 according to the first embodiment of the present invention includes: a base 21 , a lens module 22 , a filter 23 , a substrate 24 and an image sensor 25 electrically connected to the substrate 24 . The image sensor 25 is disposed on the upper surface of the substrate 24 and aligned with the lens module 22 , and incident light passes through the lens module 22 and the filter 23 to the image sensor 25 in sequence.

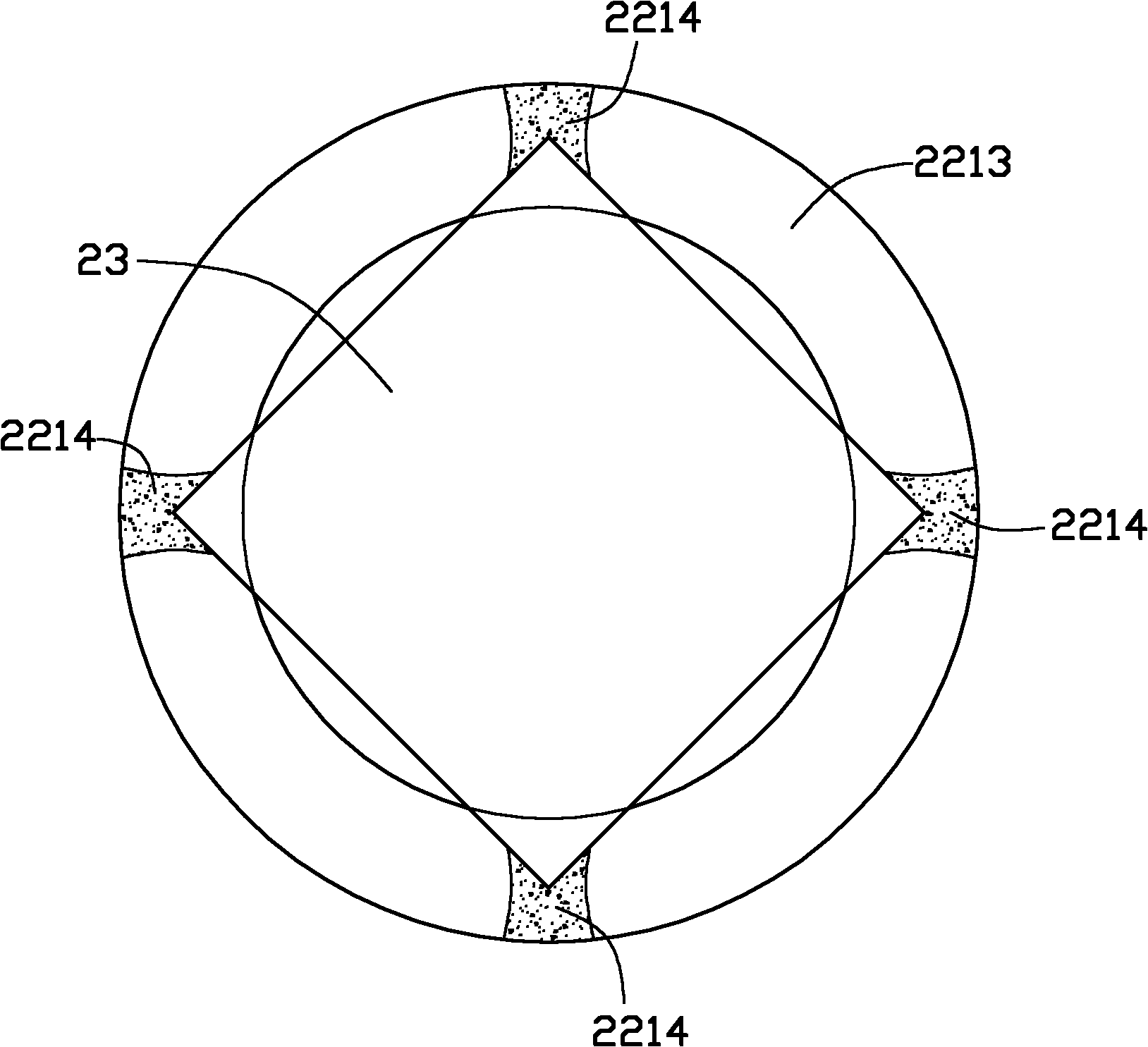

[0019] The base 21 includes a viewing tube 212 and a base 213 integrally formed with the viewing tube 212 . The viewfinder tube 212 is cylindrical and defines a threaded hole 2121 . The base 213 is rectangular and forms a receiving portion 2131 . The accommodating portion 2131 communicates with the threaded hole 2121 and is roughly a rectangular groove. The substrate 24 is fixedly disposed on the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com