Double-screw four-star-wheel compressor

A four-star wheel and compressor technology, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of reduced working efficiency, leakage, and increased gap between screw grooves and star gear teeth of compressors, etc., and achieves improvement Efficiency reduction, compression effect improvement, gap avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Attached to the following Figure 1-5 This application will be described in further detail.

[0036] The embodiment of the present application discloses a twin-screw four-star-wheel compressor.

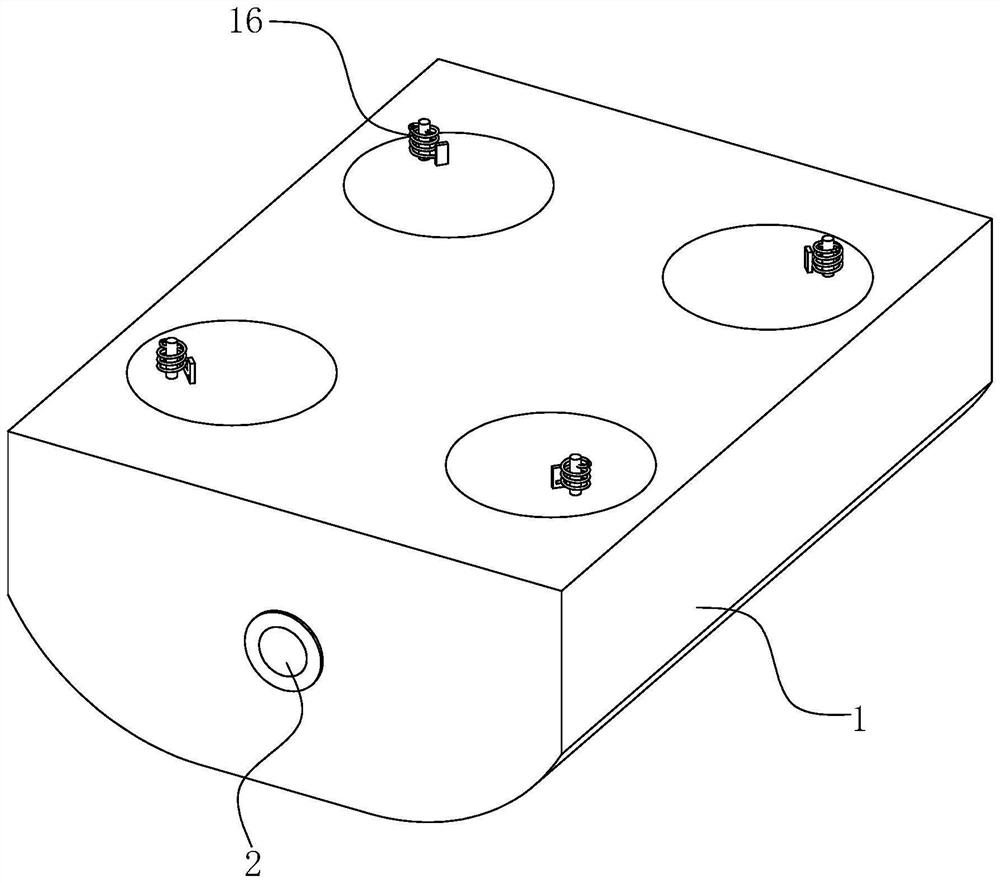

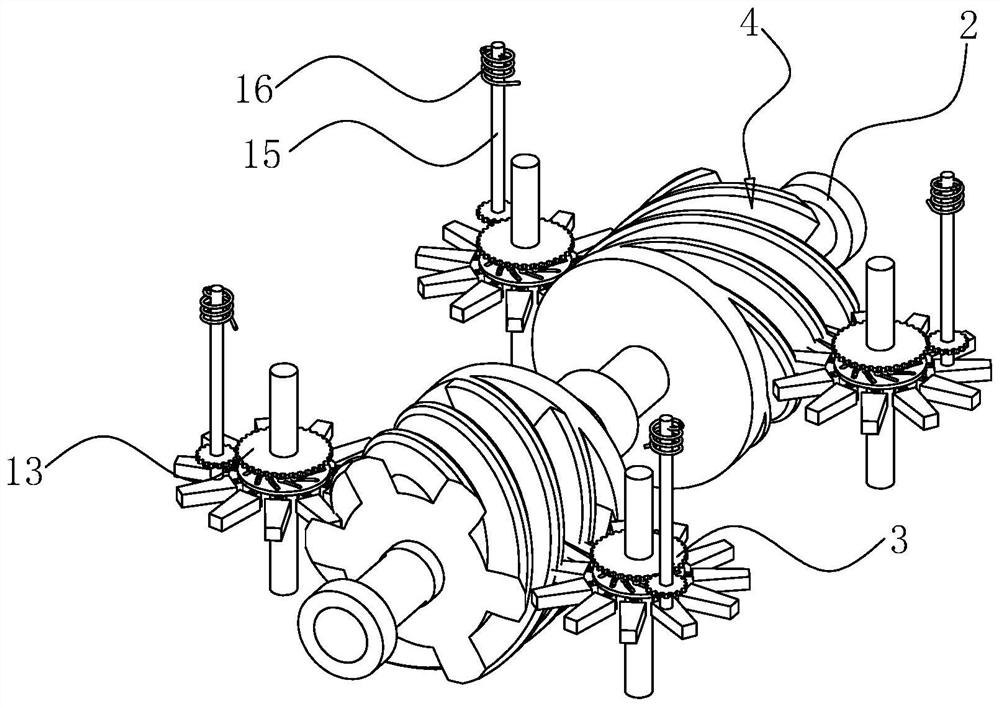

[0037] refer to figure 1 and figure 2 , a twin-screw four-star-wheel compressor comprises a casing 1, the casing 1 is made of metal material, two screws 2 are rotatably installed in the casing 1, the two screws 2 are coaxially arranged, and the junction of the two screws 2 shafts A collar is sleeved and installed, and the rotation directions are the same. A sealing ring is sleeved and installed at the end of any screw 2 , and the sealing ring is located at the ends of the screw 2 that are close to each other.

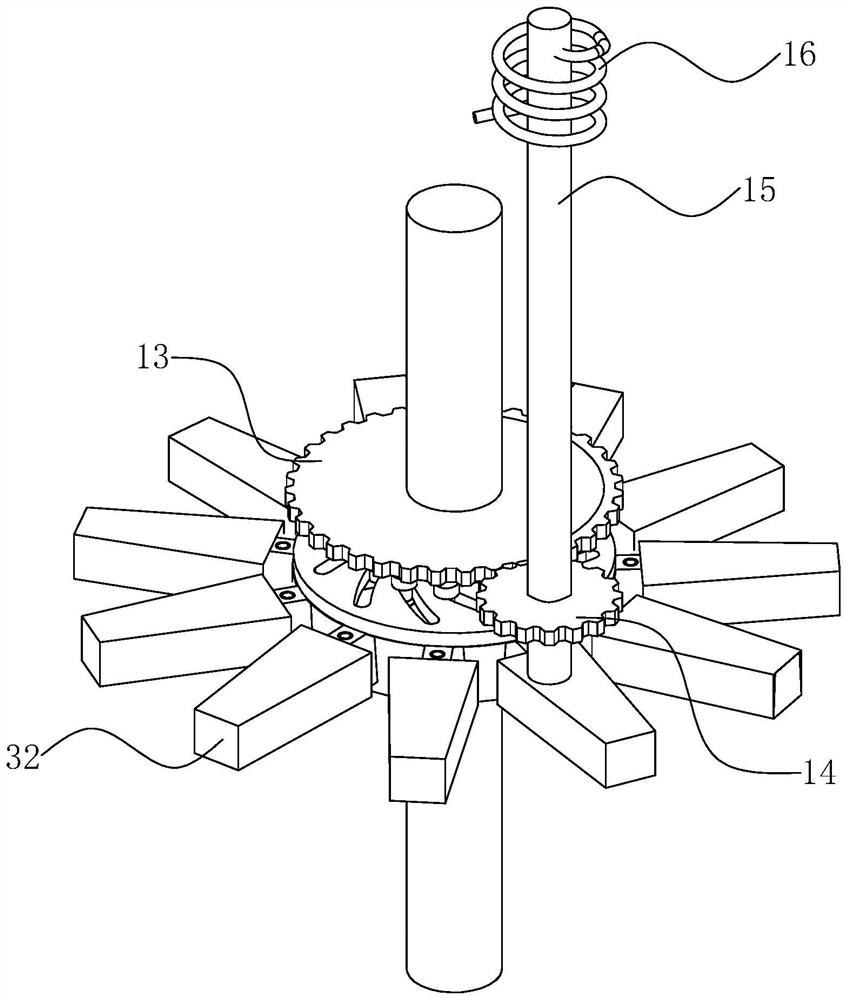

[0038] Both sides of any screw 2 are provided with star wheels 3, the number of star wheels 3 is set to 4, and the two are located on both sides of different screws 2 respectively, the axis of the star wheel 3 and the axial direction of the screw 2 are set. perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com