Electromagnetic relay

A technology of electromagnetic relays and magnetic poles, applied in the direction of electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve problems such as poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

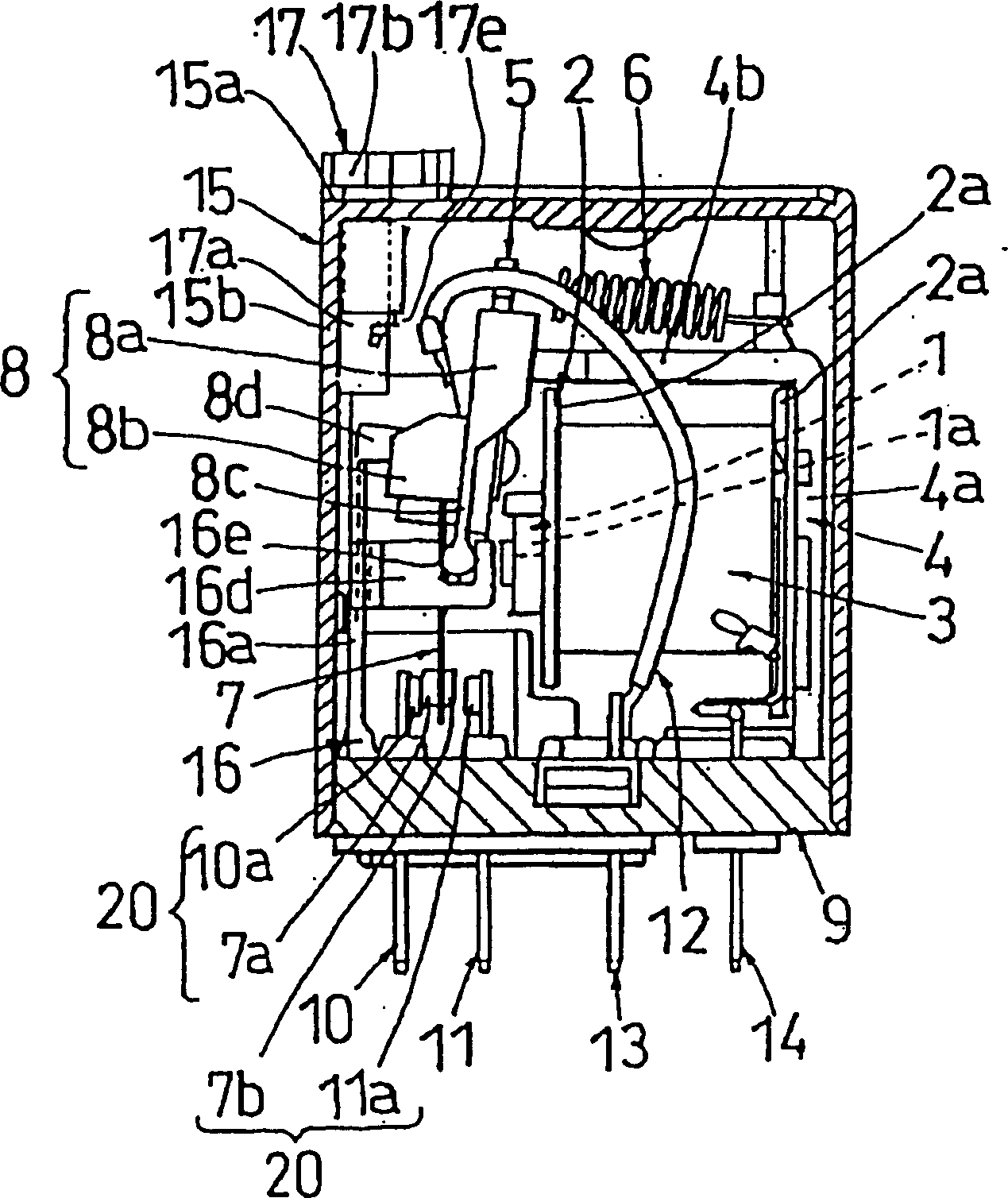

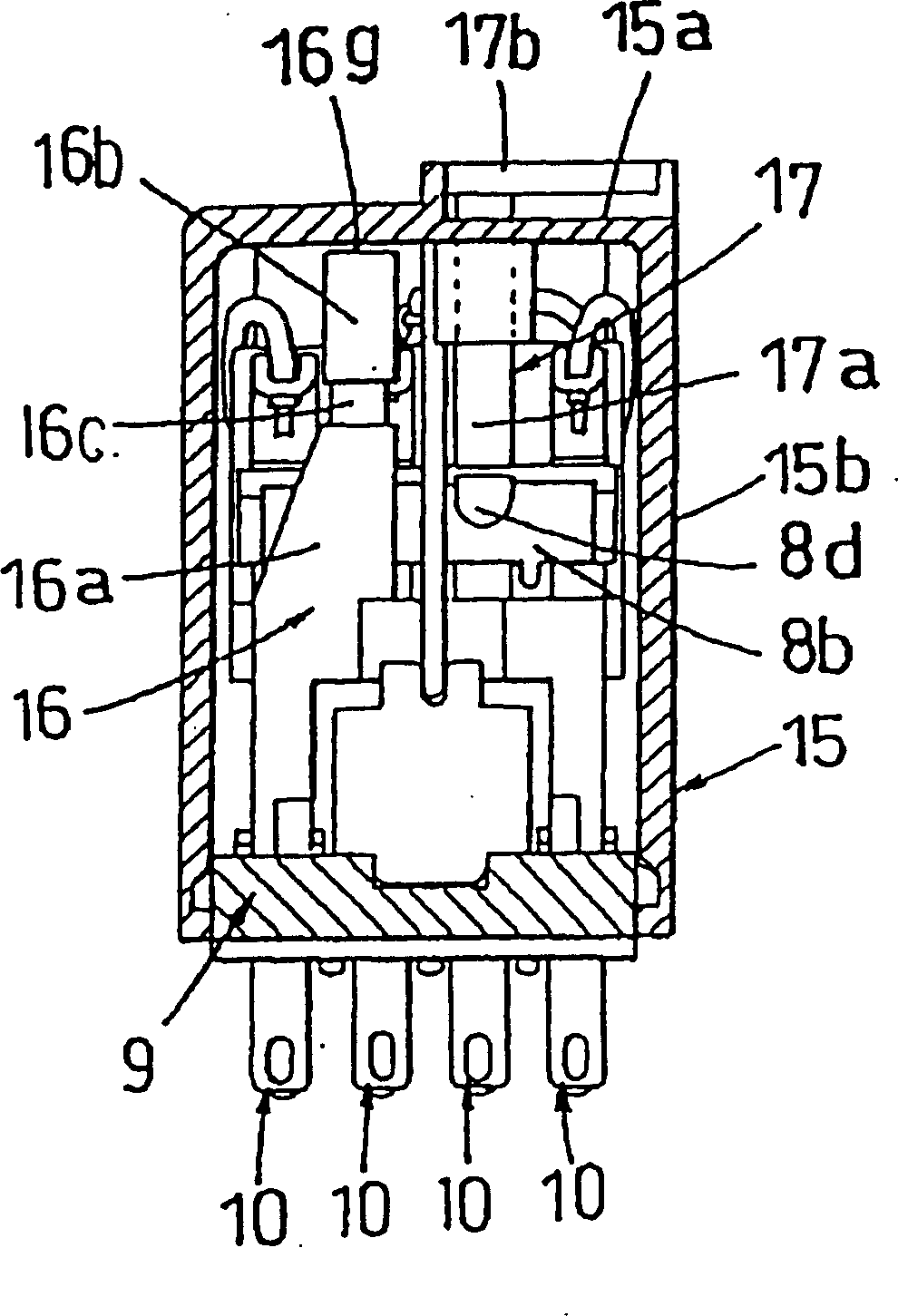

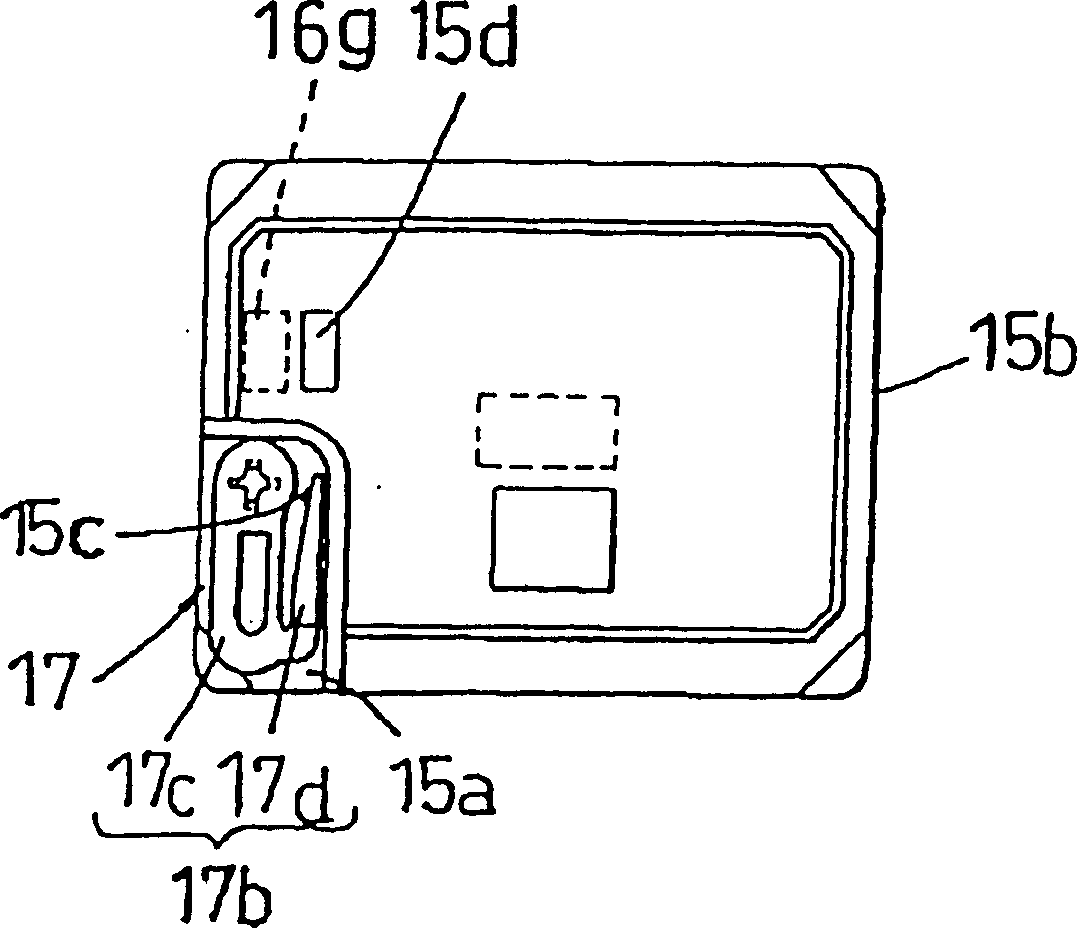

[0059] refer to Figure 1 to Figure 9 , the first embodiment of the present invention will be described. The structure of this electromagnetic relay includes: iron core 1; coil winding shaft 2; coil 3; yoke 4; armature 5; return spring 6; moving spring 7; moving part 8; substrate 9; contact terminal 11; lead wire 12; common terminal 13; coil terminal 14; case 15; display member 16;

[0060] The iron core 1 is formed of a magnetic material into a substantially round bar shape. The coil bobbin 2 is made of a molding material such as plastic, has a substantially columnar shape, and has a color 2a at both ends of a drum portion on which a coil 3 is wound. Next, the iron core 1 is inserted into the through hole in the drum portion of the coil bobbin 2 with one end protruding from the opening portion of the through hole. That is, the coil 3 is wound on the iron core 1 by the coil bobbin 2, and as a result, one end portion of the iron core 1 is formed as the magnetic pole portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com