Pressure transmitter for clean environments

A pressure sensor and transmitter technology, applied in the direction of fluid pressure measurement by changing ohmic resistance, measuring fluid pressure, measuring fluid pressure through electromagnetic components, etc., can solve the problems of not allowing pressure sensors, polluting products, sensor leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

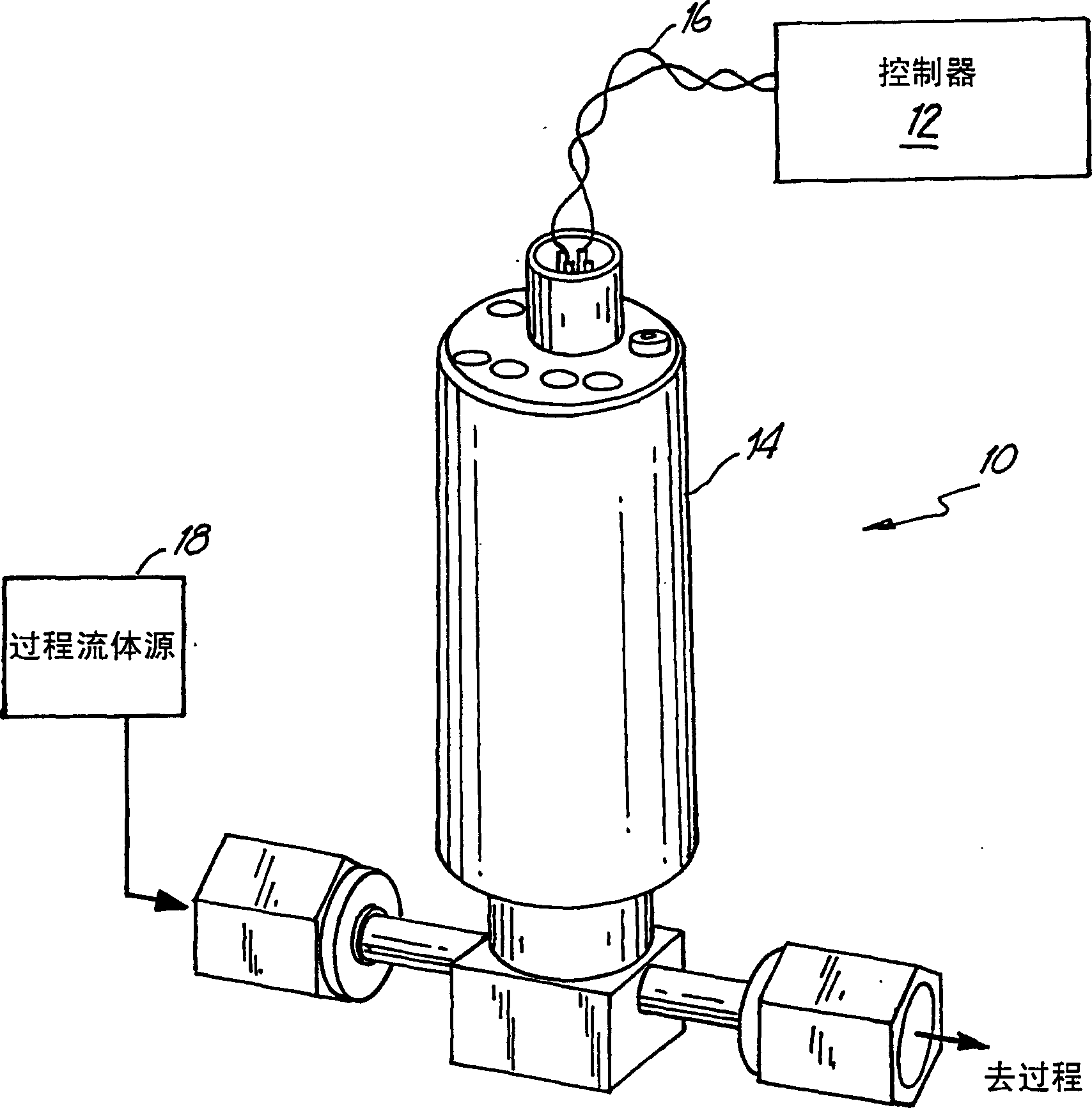

[0021] figure 1 is a schematic diagram of a process control and measurement system 10 including a controller 12 connectable to a high purity pressure transmitter (HPT) 14 via a process communication loop 16 . As shown, HPT 14 is connected to fluid source 18 to receive fluid pressure and provide a display of fluid pressure. The HPT 14 is shown in a flow-through design, with fluid from a process fluid source 18 flowing through the HPT 14 . Other embodiments where fluid does not flow through the HPT are discussed later in the specification. While a pair of wires are shown connecting controller 12 to HPT 14, any suitable number of wires may be used. Additionally, any suitable process communication protocol for communicating HPT 14 and controller 12 may be used, including, for example, Bus Addressed Remote Translator (HART®), FOUNDATION TM Fieldbus, or any other suitable protocol. Essentially, HPT 14 provides controller 12 with an indication of the pressure of the process fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com