Multi-axis load cell and manufacturing method thereof

A technology of load and unit body, which is applied in the field of moment load unit, and can solve problems such as inability to measure moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

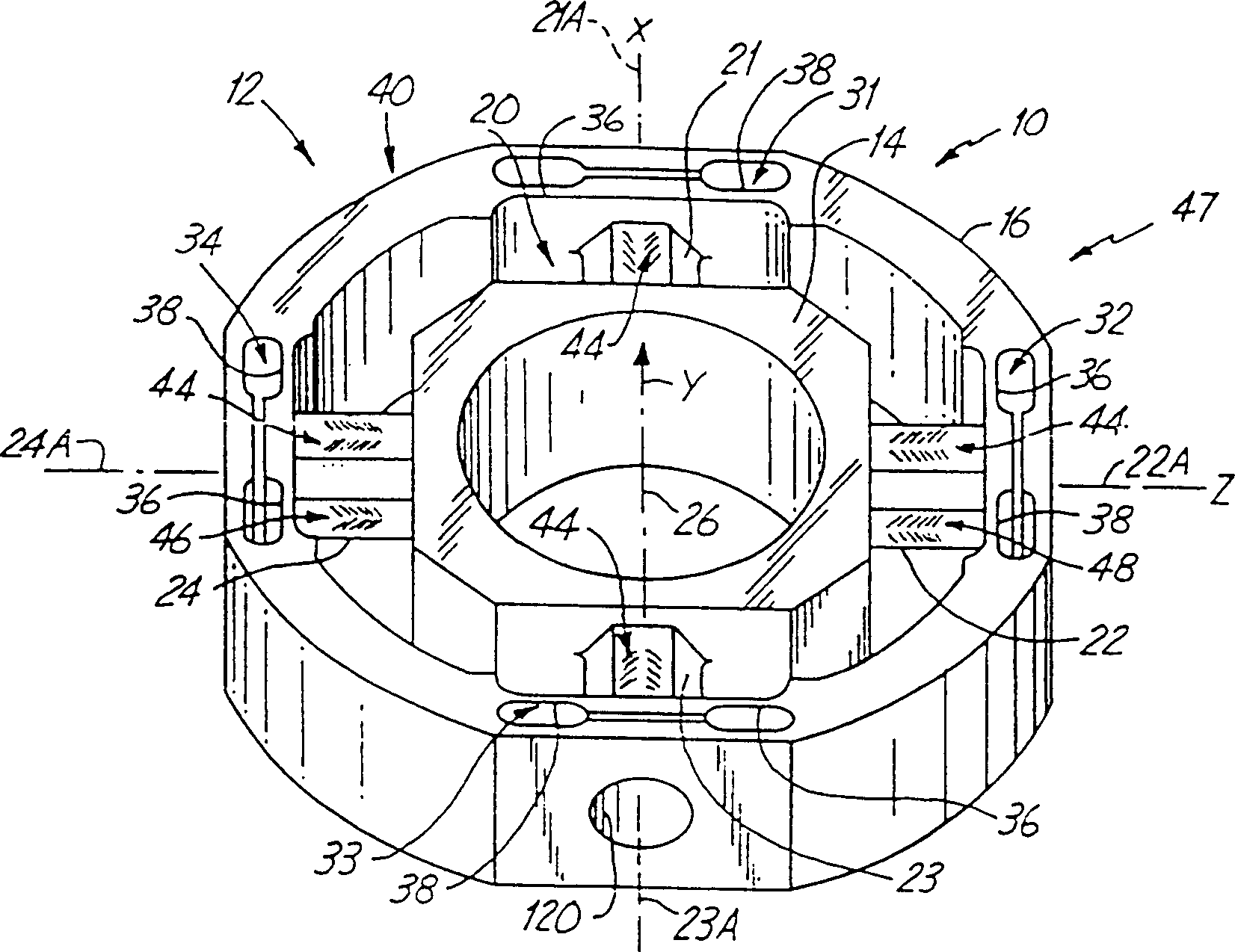

[0022] figure 1 A first embodiment of the load cell 10 of the present invention is illustrated. The load cell 10 preferably comprises a unitary body 12 of the invention which is formed from one piece of material. The body 12 includes a rigid central hub 14 concentric with a rigid ring 16, and a plurality of radial tubes 20 connect the central hub 14 and the ring 16 together. In the illustrated embodiment, the plurality of radial tubes 20 consists of four tubes 21 , 22 , 23 and 24 . Each of the tubes 21 - 24 extends from the central hub 14 to the ring 16 along a respective longitudinal axis 21A, 22A, 23A, 24A. Preferably, axis 21A is aligned with axis 23A and axis 22A is aligned with axis 24A. Additionally, axes 21A and 23A are perpendicular to axes 22A and 24A. Although four radial tubes 20 are shown here, it should be understood that any number of tubes 20 three or more may be used to connect the central hub 14 to the collar 16 . Preferably, a plurality of radial tubes 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com