Wiper blade for windshields, erpecially automobile windshields, and method for production thereof

A windshield and wiper technology, applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve problems such as teaching proves to be difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

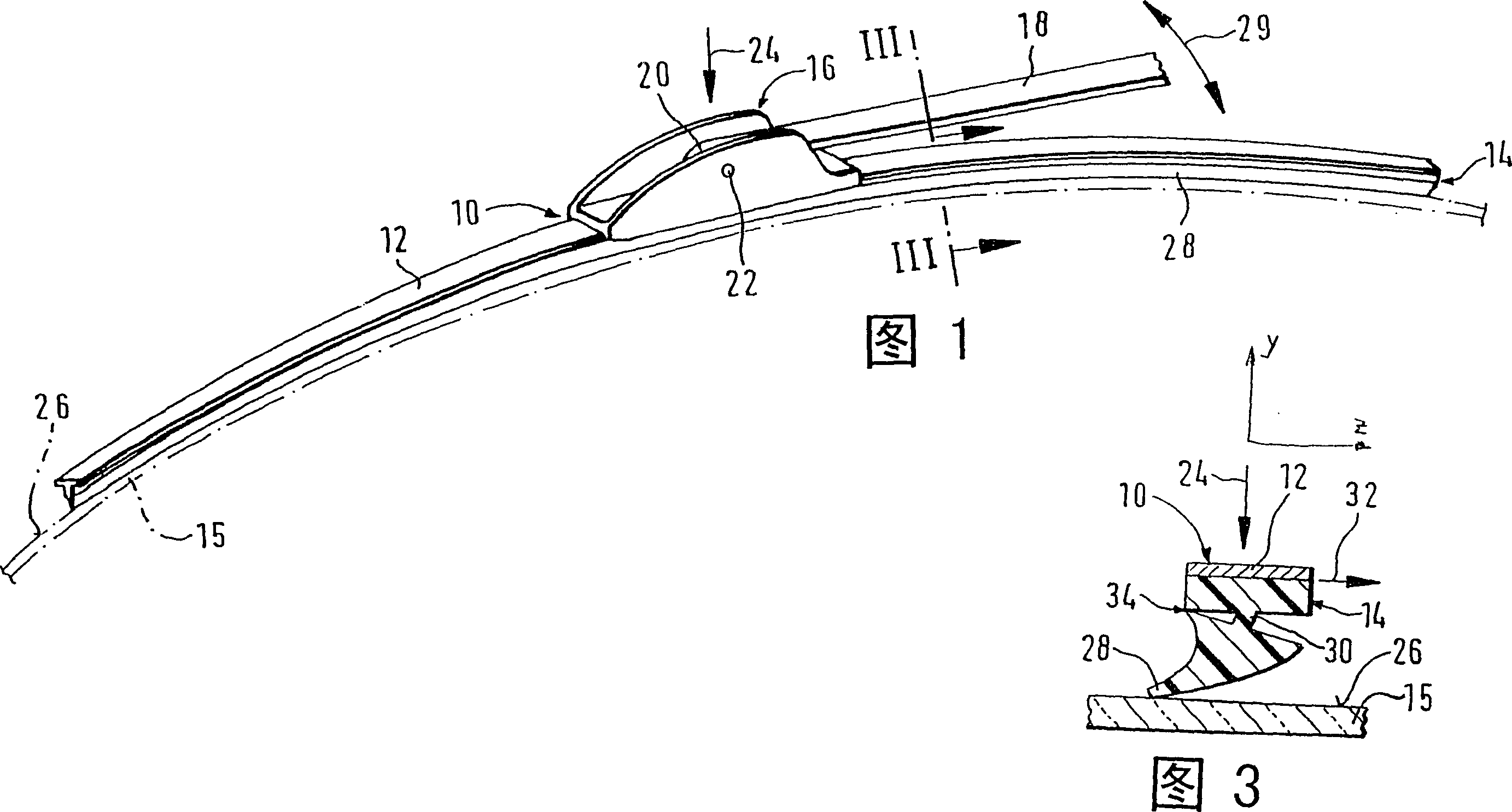

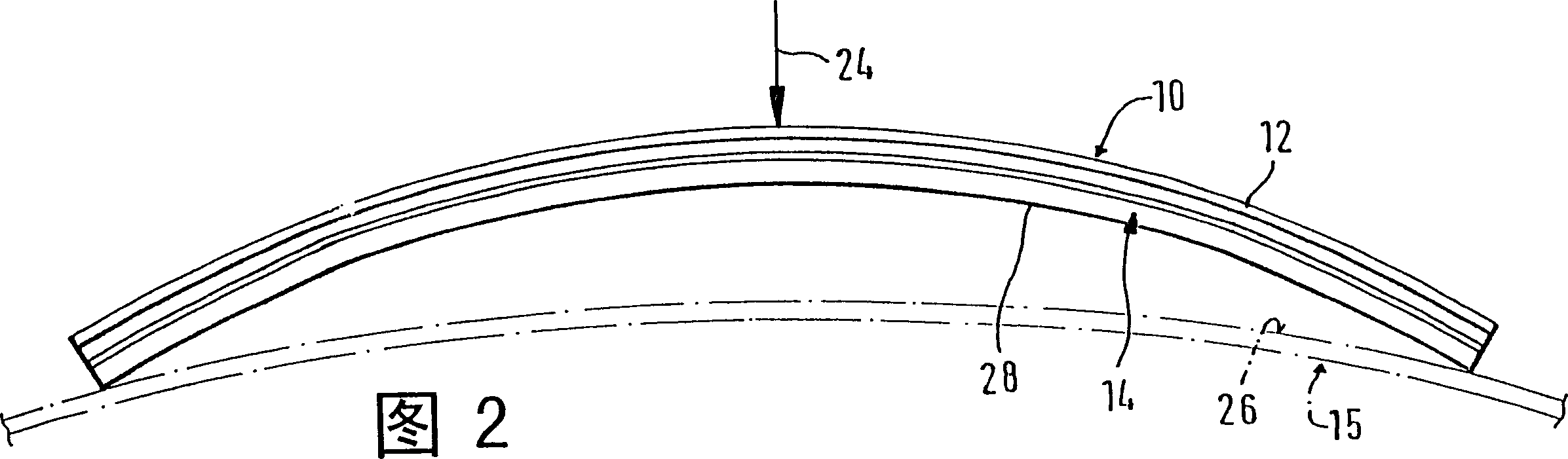

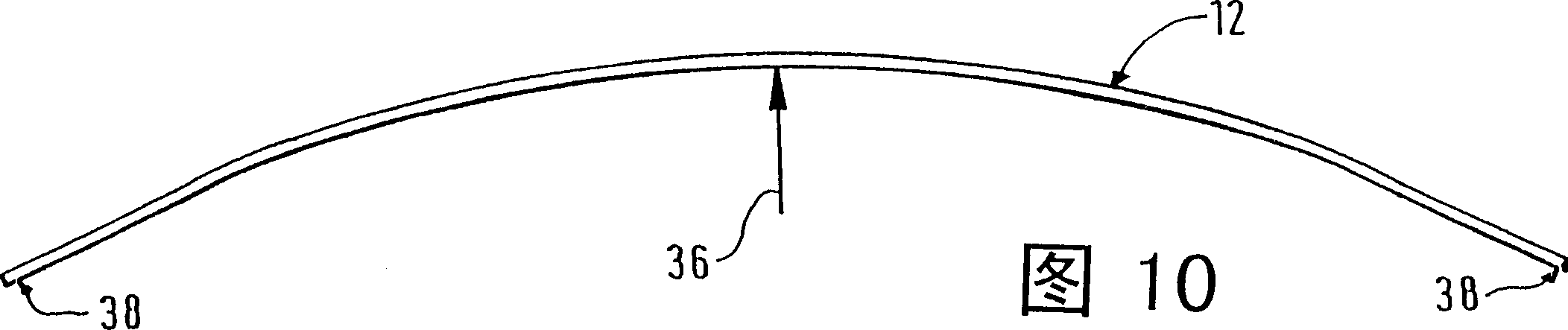

[0027] The wiper blade 10 shown in FIG. 1 has an elongated elastic carrier element 12 , also referred to as a flat beam, for the wiper blade 14 , which is shown separately in FIG. 10 . As can be seen from FIGS. 1 , 3 and 4 , the carrier element 12 and the wiper blade 14 are connected to one another with their longitudinal axes parallel. On the top of the carrier element 12 facing away from the glass 15 to be wiped (shown with dotted lines in FIG. 1 ), a connecting device 16 as a connecting mechanism is installed, by means of which the wiper blade 10 can be connected to the automobile. The driven wiper arm 18 of the body is detachably connected. An elongated, rubber-elastic wiper strip 14 is mounted on the underside of the carrier element 12 facing the glass 15 .

[0028] A hook is formed on the free end 20 of the wiper arm 18 as a counter-connection device, which hook can hold a hinge pin 22 belonging to the connection device 16 of the wiper blade 10 . The detachment protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com