Method for manufacturing thin-film magnetic head and manufacturing device thereof

A technology of thin-film magnetic head and manufacturing method, which is applied to the direction of magnetic head using thin film, magnetic recording head, and the surface of magnetic head, which can solve the problems of unstable floating characteristics and scratches, so as to improve quality and effective productivity, and prevent scratches , The effect of reducing the setting error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

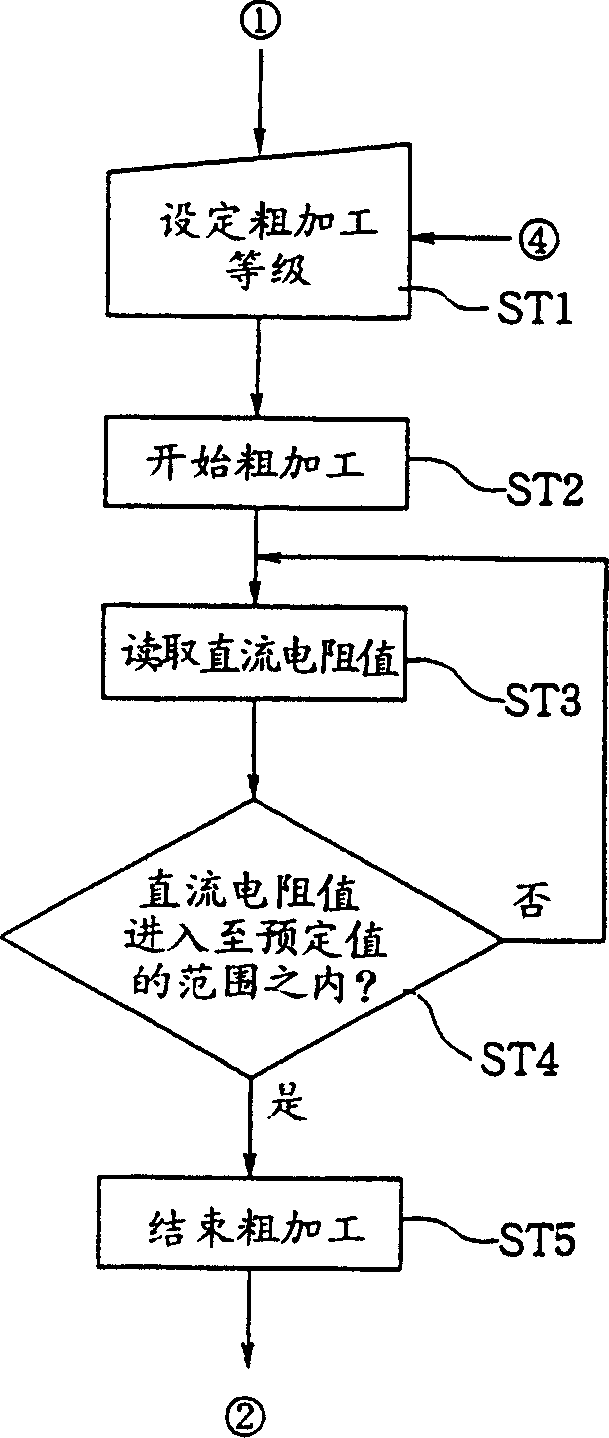

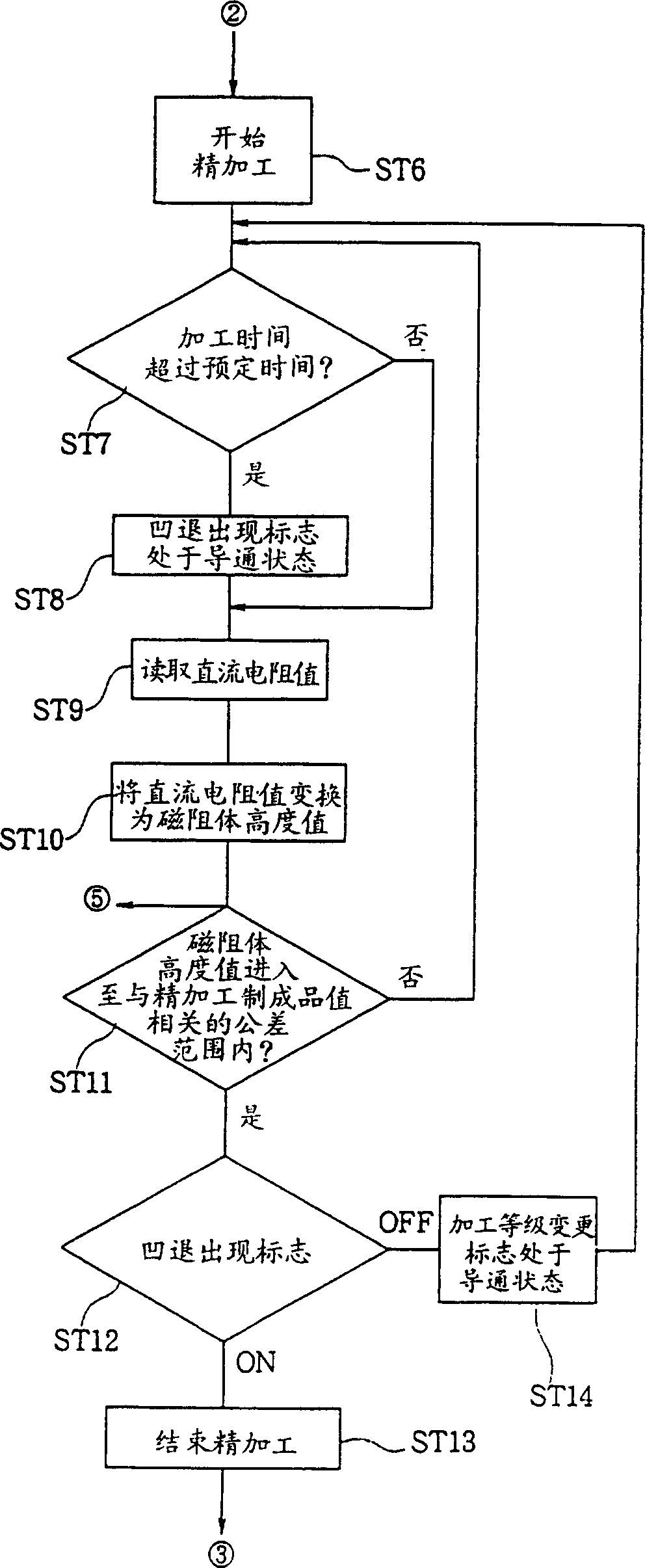

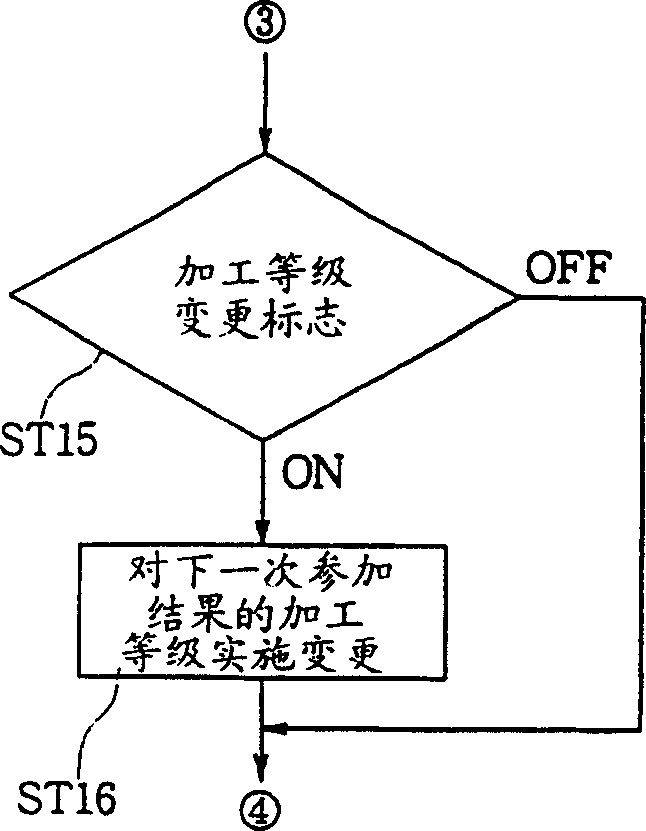

[0078] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0079] as Figure 5 As shown, the manufacturing process of the thin film magnetic head is made of such as alumina-titanium carbide (Al 2 o 3 - On a substrate 2 made of materials such as TiC), a number of thin film magnetic elements 1 are formed through a thin film processing procedure. Such as Figure 5 The substrate 2 shown is in the shape of a disc, and several thin film magnetic elements 1 located on the substrate 2 are formed in a row at certain intervals, and of course they can also be formed in several rows.

[0080] 7 is a partially enlarged cross-sectional view showing the thin-film magnetic element 1 formed on the rod-shaped slider (slider) 3 cut along the exposed surface (ABS surface) 3a. The thin-film magnetic element 1 is a laminated compound element composed of an inductive magnetic head part and a magnetoresistive magnetic head part using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com