Method of detecting criticality of servo control system

A technology of servo control system and control parameters, which is applied in the field of servo parameter adjustment of the servo control system, and can solve problems such as damage to machinery, adjustment, and large oscillation sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] best practice

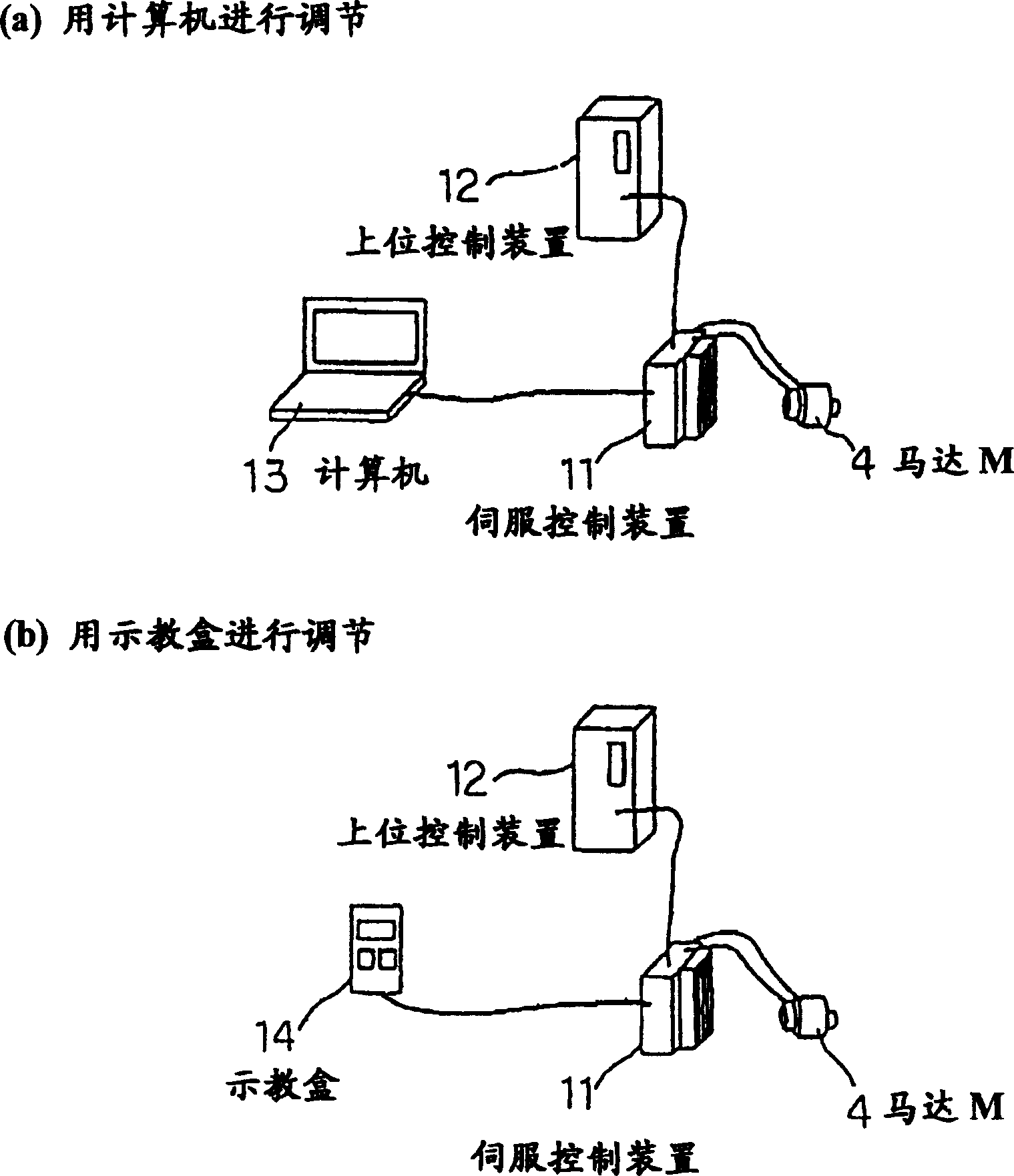

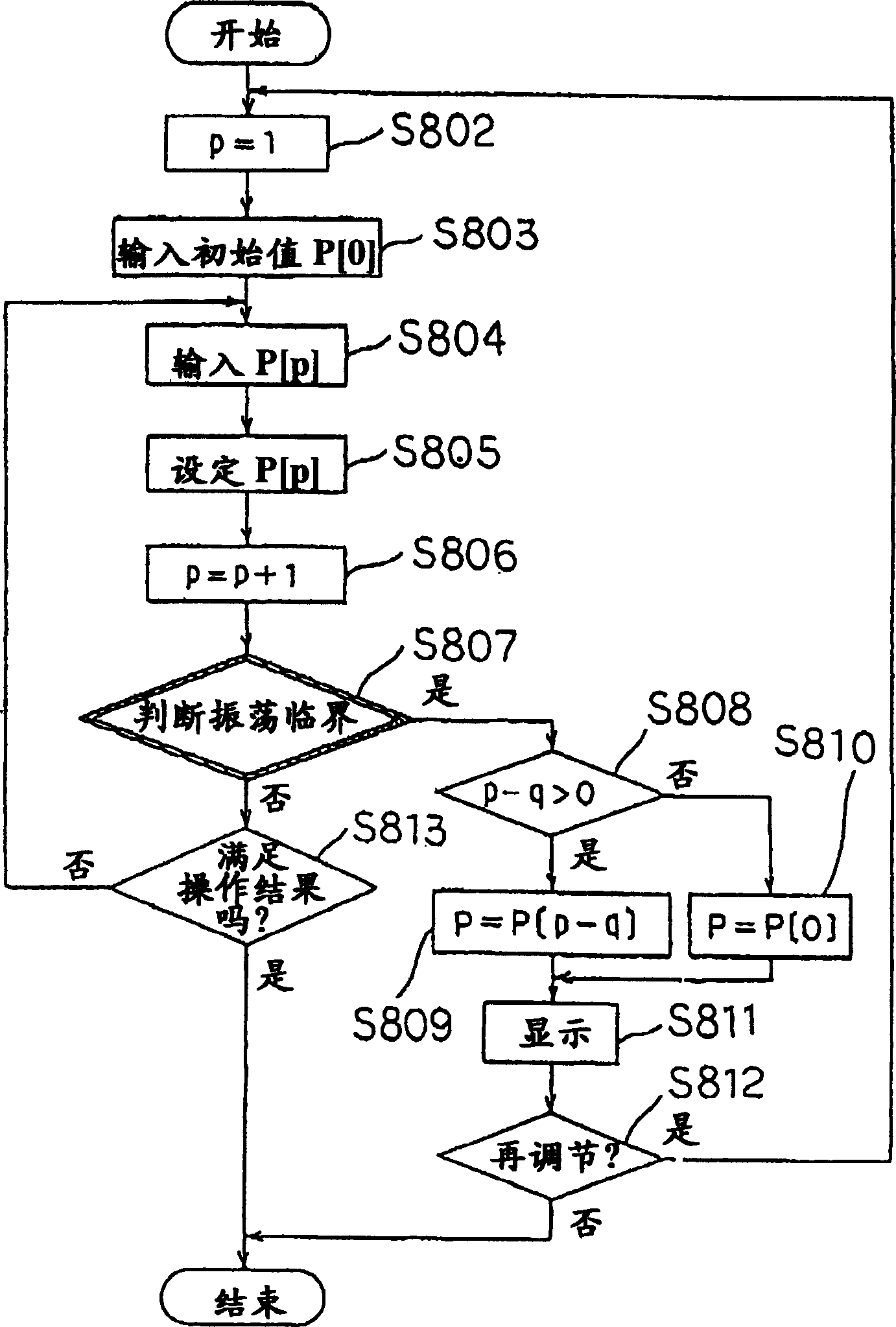

[0031] Hereinafter, a method for detecting a critical oscillation of a servo control system according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings. In all the drawings, constituent elements attached with the same symbols represent the same components.

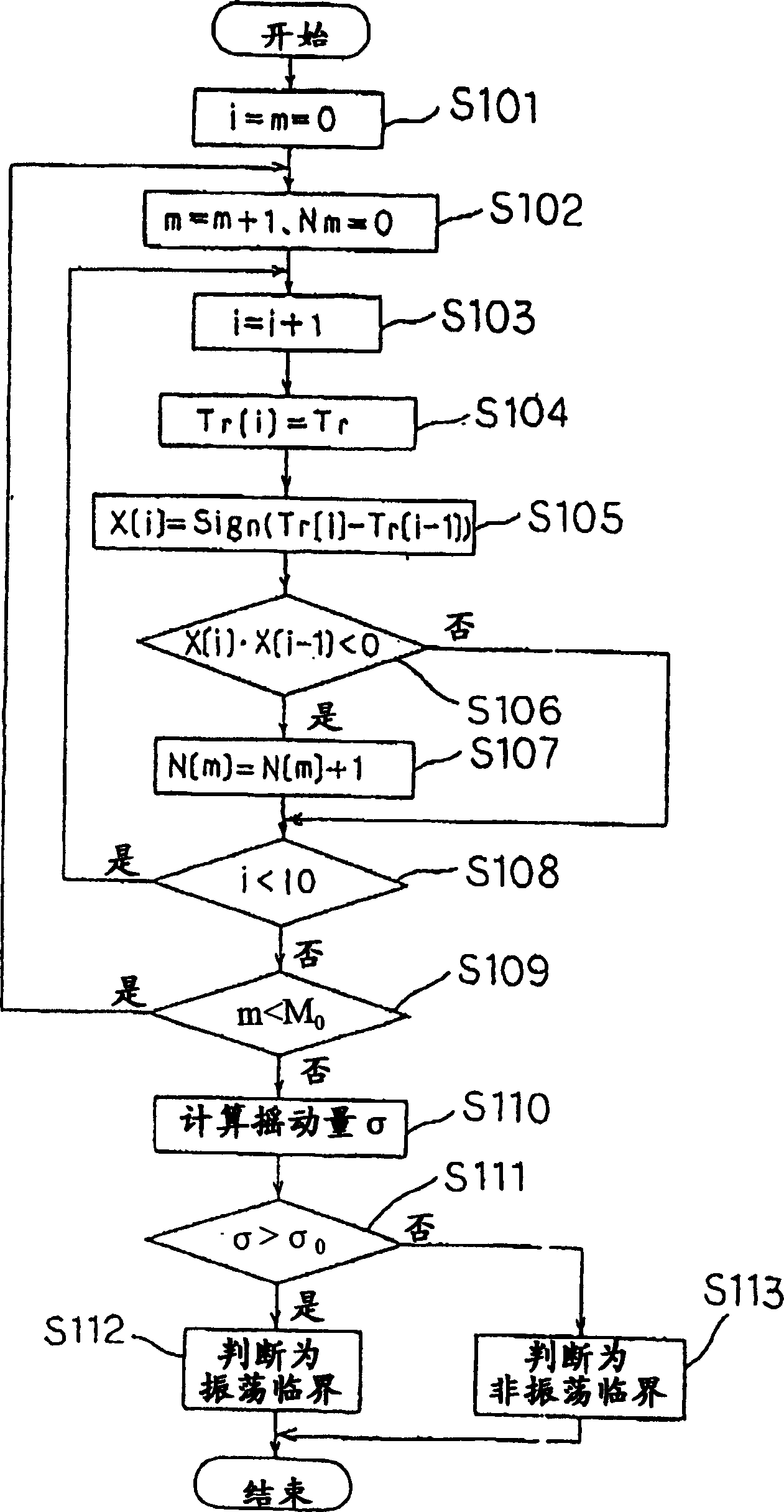

[0032] The oscillation critical detection method of the servo control system in this embodiment focuses on Figure 9 The relationship between control parameters such as proportional gain Kv, reciprocal Ki of integral time constant, differential time Kd, etc., torque command Tr, and vibration frequency component of speed feedback amount ω, that is, shaking amount, is shown. In the vibration critical detection method of the servo control system of this embodiment, the value of the control parameter is set to a value that increases step by step, and at the same time, the torque command Tr and the shaking amount of the speed feedback amount...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap