Apparatus for supplying lubricating grease to sliding arm

A technology of lubricating grease and sliding arm, which is applied in the direction of engine lubrication, lubricating parts, mechanically driven excavators/dredgers, etc., which can solve the problems of low operating efficiency, waste of lubricating grease, supplying lubricating grease, etc., and achieve improved operation Efficiency, ease of grease supply, prevention of useless consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

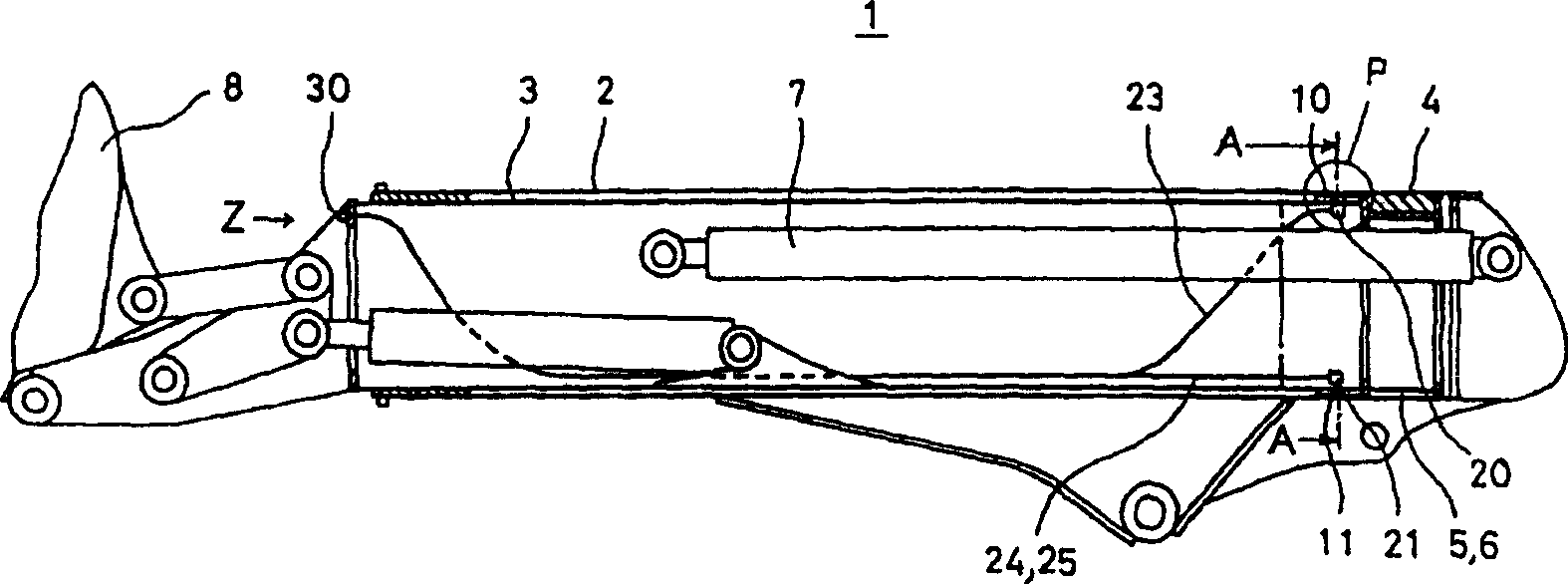

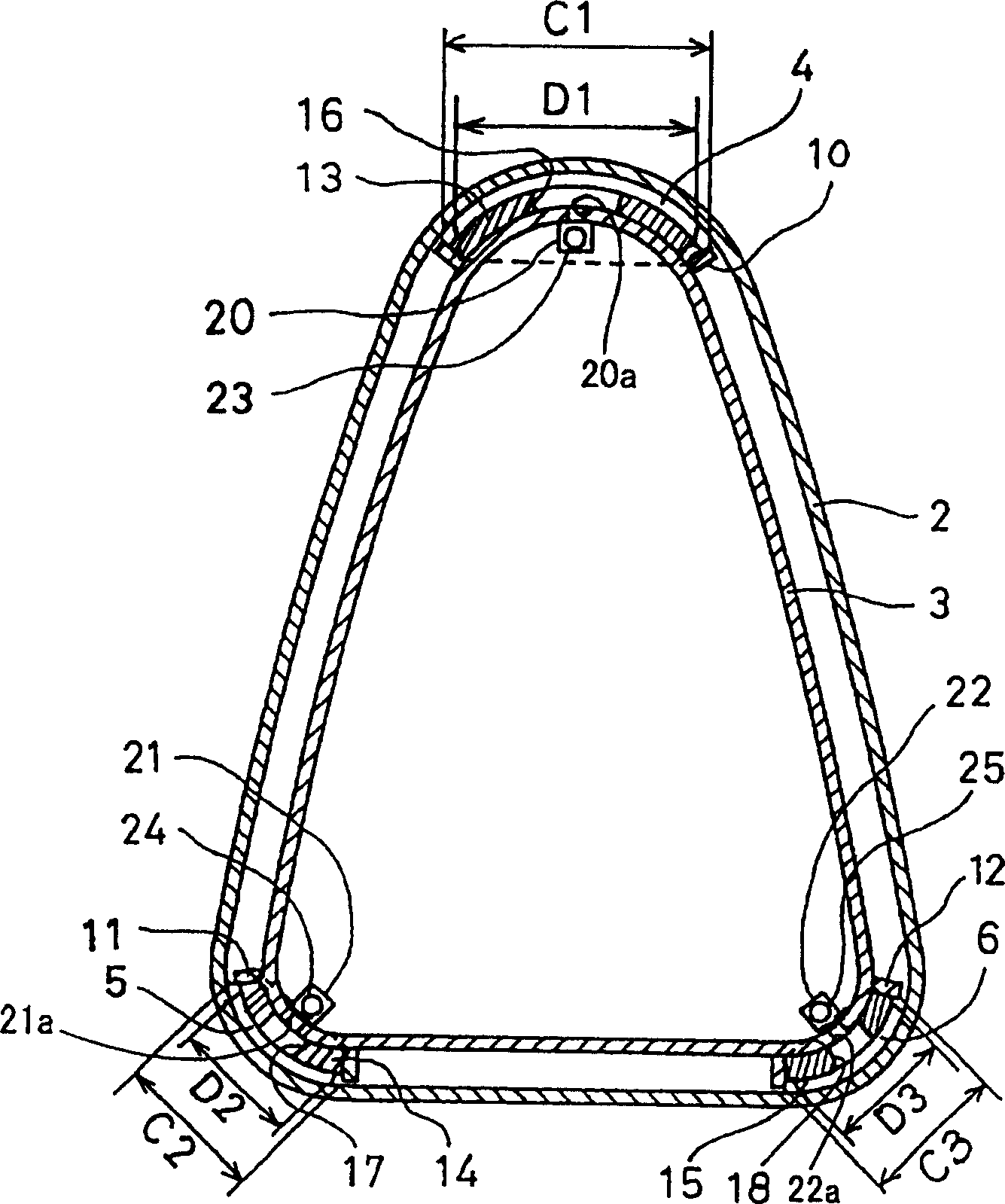

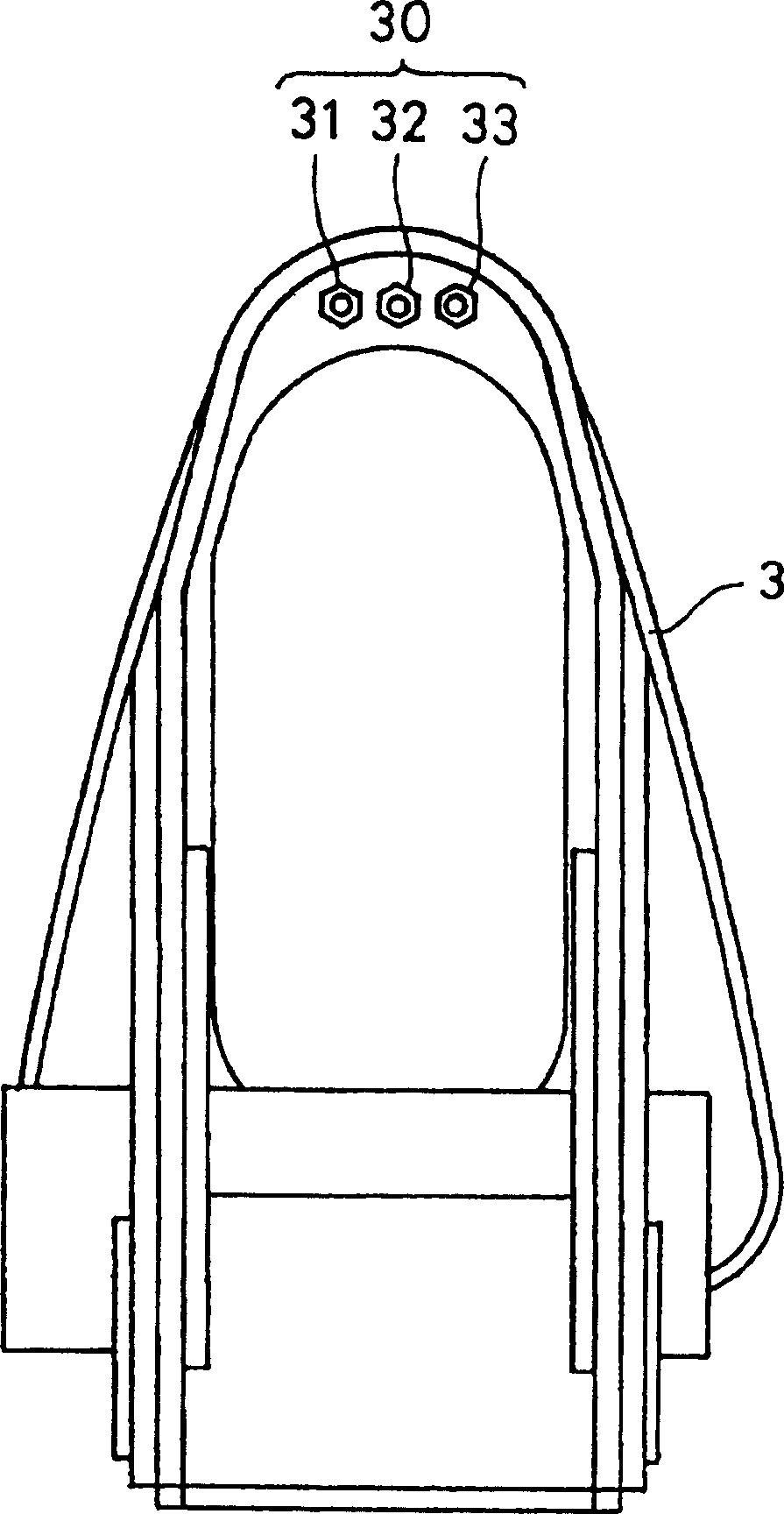

[0018] figure 1 A side cross-sectional view showing an example of the slide arm 1 equipped with the grease supply device of the present invention. figure 2 yes figure 1 A-A direction view. exist figure 1 , 2 Among them, the inner arm 3 of the working machine 8 with a bucket at the front end is telescopically inserted into the outer wall 2 having a triangular cross-sectional shape, and the shape of the inner arm 3 is similar to the triangular shape of the outer arm 2 . Sliding pads 4, 5, 6 are respectively installed on three positions of the base end outer peripheral surface of the inner arm 3, the upper front end and the lower left and right front ends, and their outer peripheral surfaces are in contact with the inner surface of the outer arm 2 to form a sliding surface. . Grease grooves 10 , 11 , 12 which are surrounded by a certain range and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com