Rotor position detecting method of brushless DC motor having no sensor

A technology of rotor position detection and brushed DC motor, which is applied in the direction of electronic commutator, electronic commutation motor control, electrical components, etc., can solve the problems of motor out of slot and difficult to return to normal state, and achieve the effect of stable driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

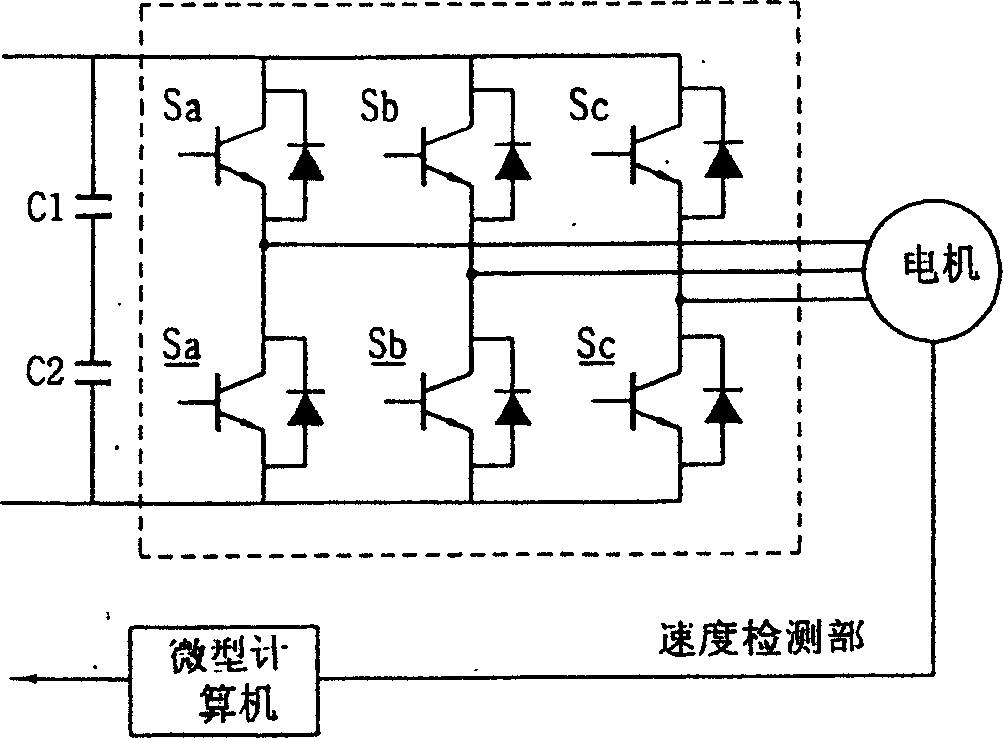

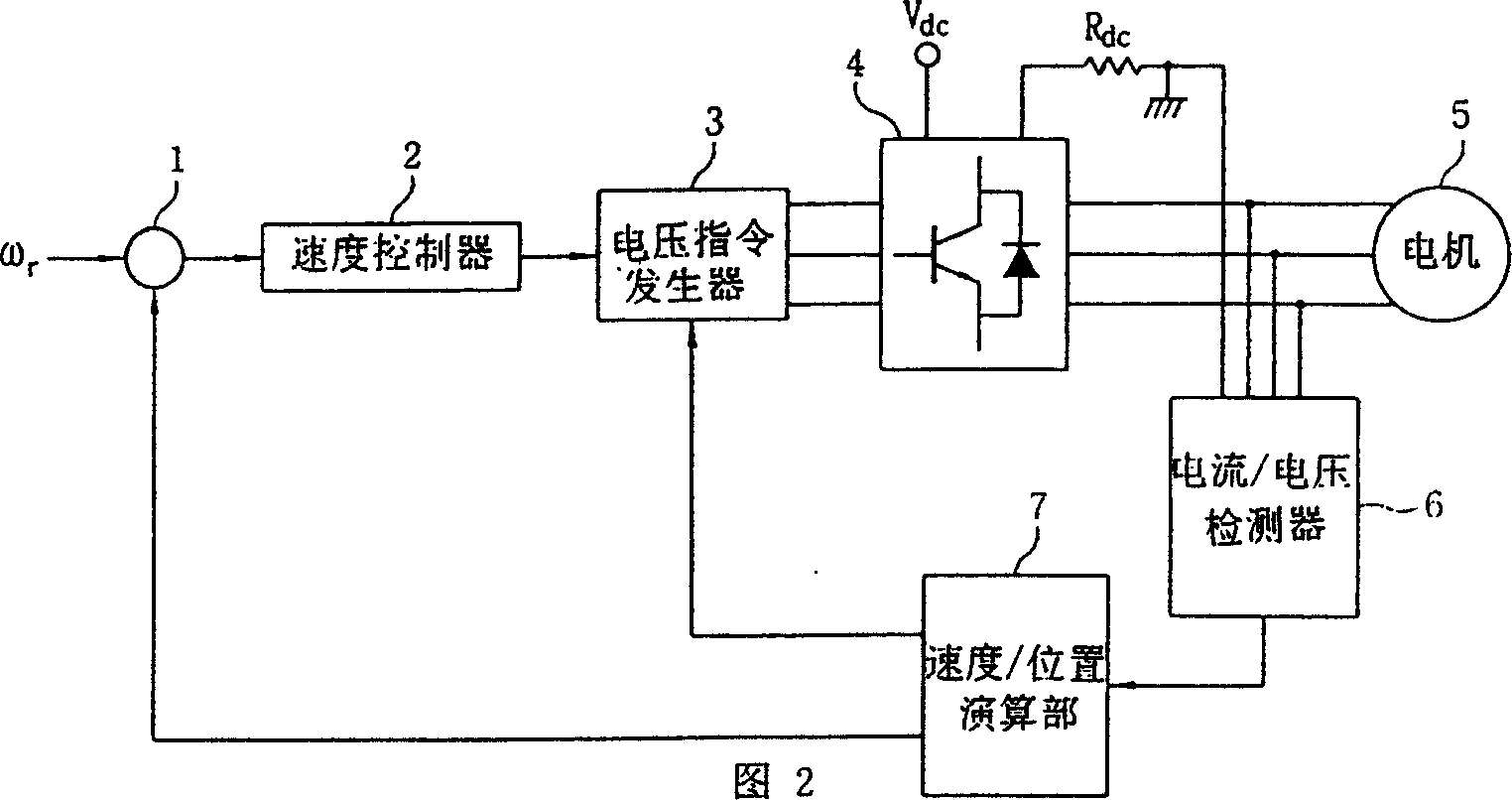

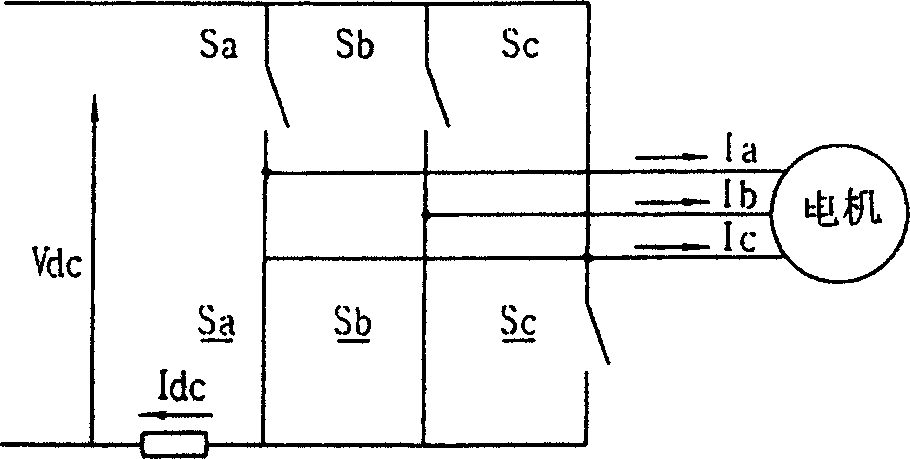

[0037] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0038] The invention is a sensorless rotor position detection method for a brushless DC motor. The method and the device used are the same as those of the prior art shown in FIG. 2 . Fig. 4 is a working flow diagram of the present invention. As shown in Figure 4, the sensorless rotor position detection method of the brushless DC motor of the present invention includes the following steps: the first step: judging whether the user has selected the position information correction mode; the second step: if it is not the position information correction mode, then Use the current and voltage of 'A, B, C' phases to estimate the position of the main rotor and drive the motor; the third step: if it is the position information correction mode, cut off the phase currents of 'A, B, C' phases , to detect the phase voltages of the 'A, B, C' phases; the fourth step: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com