Coal mining method adopting 3.55m monocolumn three-two row pipe burying top board

A coal mining method and single-column technology, applied in ground mining, earth square drilling, underground mining, etc., can solve problems such as unfavorable roof support, increased workload, and many electromechanical accidents, so as to be beneficial to health and reduce Labor intensity, the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

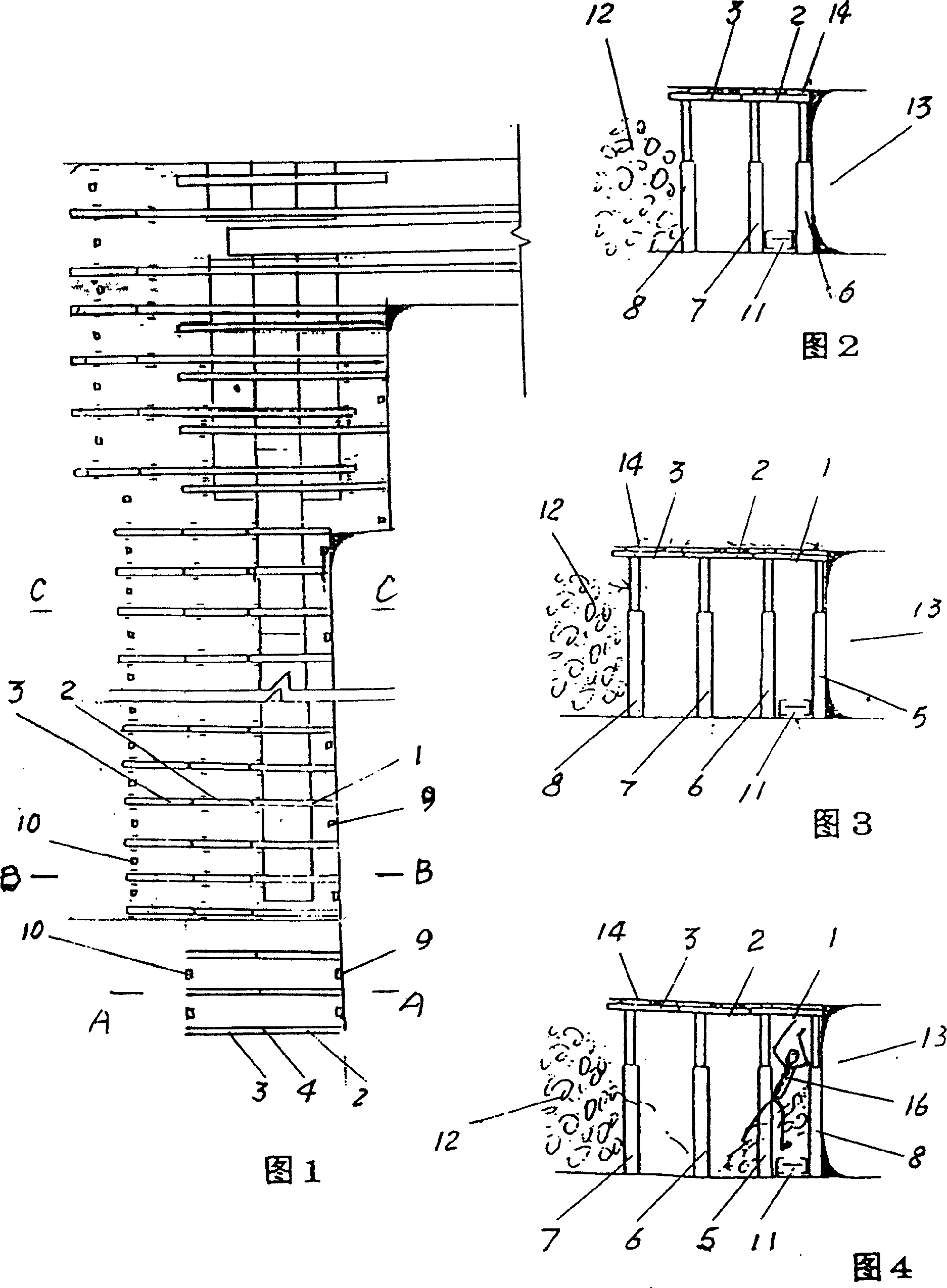

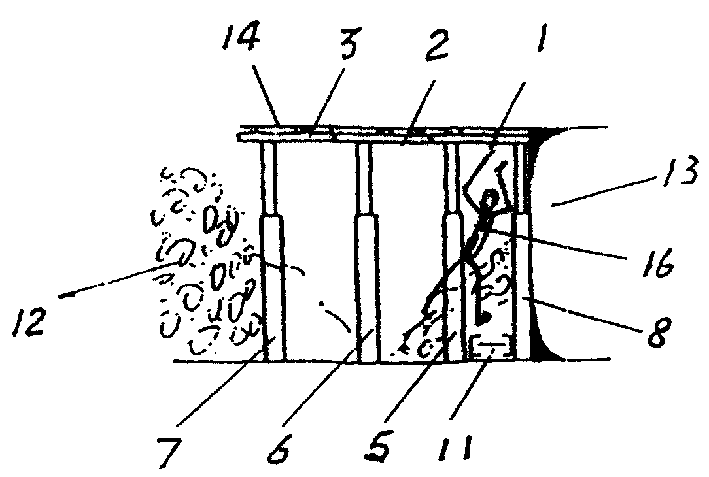

[0028] Please refer to Fig. 1, Fig. 2, Fig. 3 and Fig. 4. The present invention is a coal mining method using a 3.55m single column with three or two rows to manage the roof. The model of the single hydraulic support column is DZ-3.55 / 100. The beam model is HBJD-1200, which is characterized by:

[0029] The working order of the method is:

[0030] ① On the mining face, No. 2 support column 6, No. 3 support column 7, and No. 4 support column 8 jointly support the hinged No. 2 roof beam 2 and No. 3 roof beam 3, forming a second row of roof beam support. The rock top 14 is supported by the hinged roof beam, and the mining face is in the state of minimum distance control, at this time, the coal is shot and dropped, and the height of the coal dropped on the scraper conveyor 11 is above 1.5m;

[0031] ② Mining personnel 16 pedal on the coal pile, hang No. 1 roof beam 1, and hinge it with No. 2 roof beam 2 to form three rows of roof beam support for No. 1, No. No. support column 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com