Metal bat with pressurized bladder in hitting zone

A technology of metal balls and bats, applied in the direction of rackets, sports accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In describing the preferred embodiment of the invention illustrated in the drawings, specific terminology will be employed for the sake of clarity. It is not intended, however, to limit the invention to the specific embodiments and terminology chosen; it should be understood that each specific term includes all technically equivalent terms which could be used in a similar manner to achieve similar purpose.

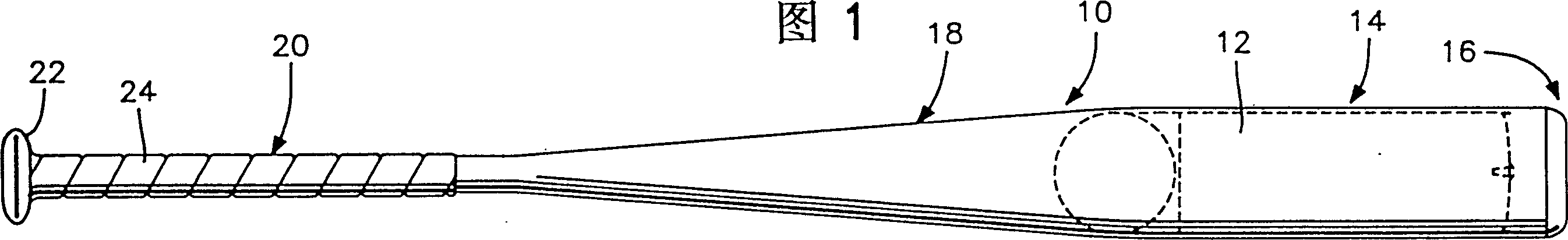

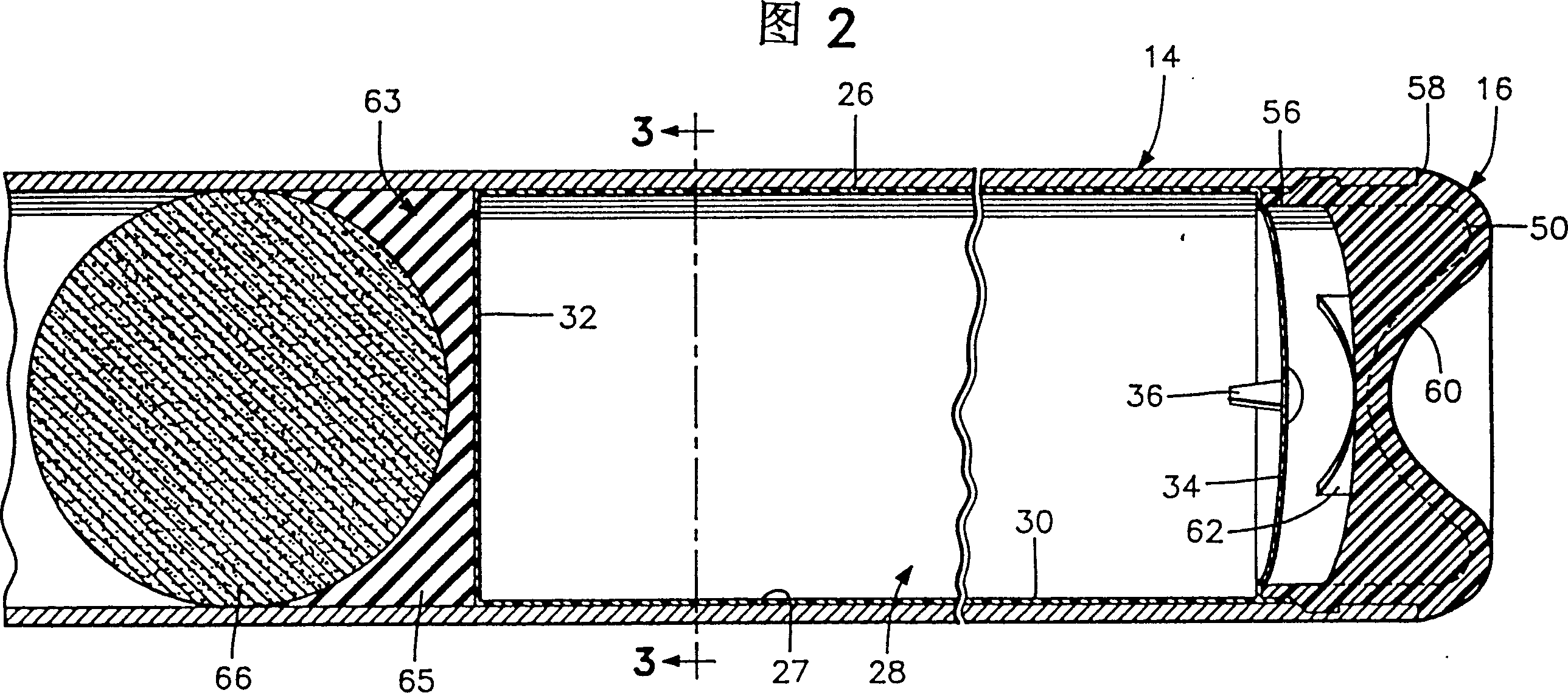

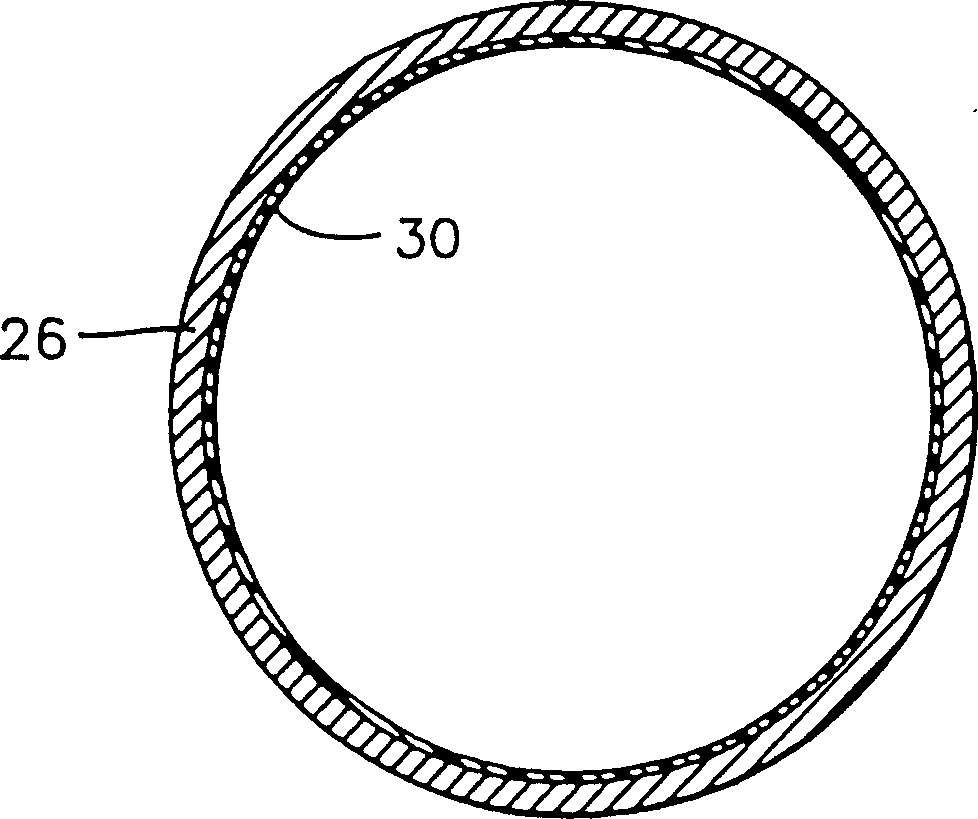

[0042] Referring to the embodiment illustrated in Figures 1 to 4, the hollow metal bat is generally indicated by the reference numeral 10 and includes a hollow shaft 12 extending the length of the bat. Included at the distal end of the shaft 12 is a hitting zone generally indicated by reference numeral 14 which is provided with an end cap 16 to form a distal closure. Shaft 12 also includes a tapered transition region 18 extending from the proximal end of striking zone 14 to the handle generally indicated by reference numeral 20 . The handle 20 includes a cap 22 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com