Axial positioning device of heat transfer pipe internal rotation cleaning element

An axial positioning and heat transfer tube technology, which is used in cleaning heat transfer devices, rotating equipment cleaning, lighting and heating equipment, etc. It can solve the problems of difficult dirt cleaning resistance, reduced rotation torque of rotating cleaning elements, and low flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

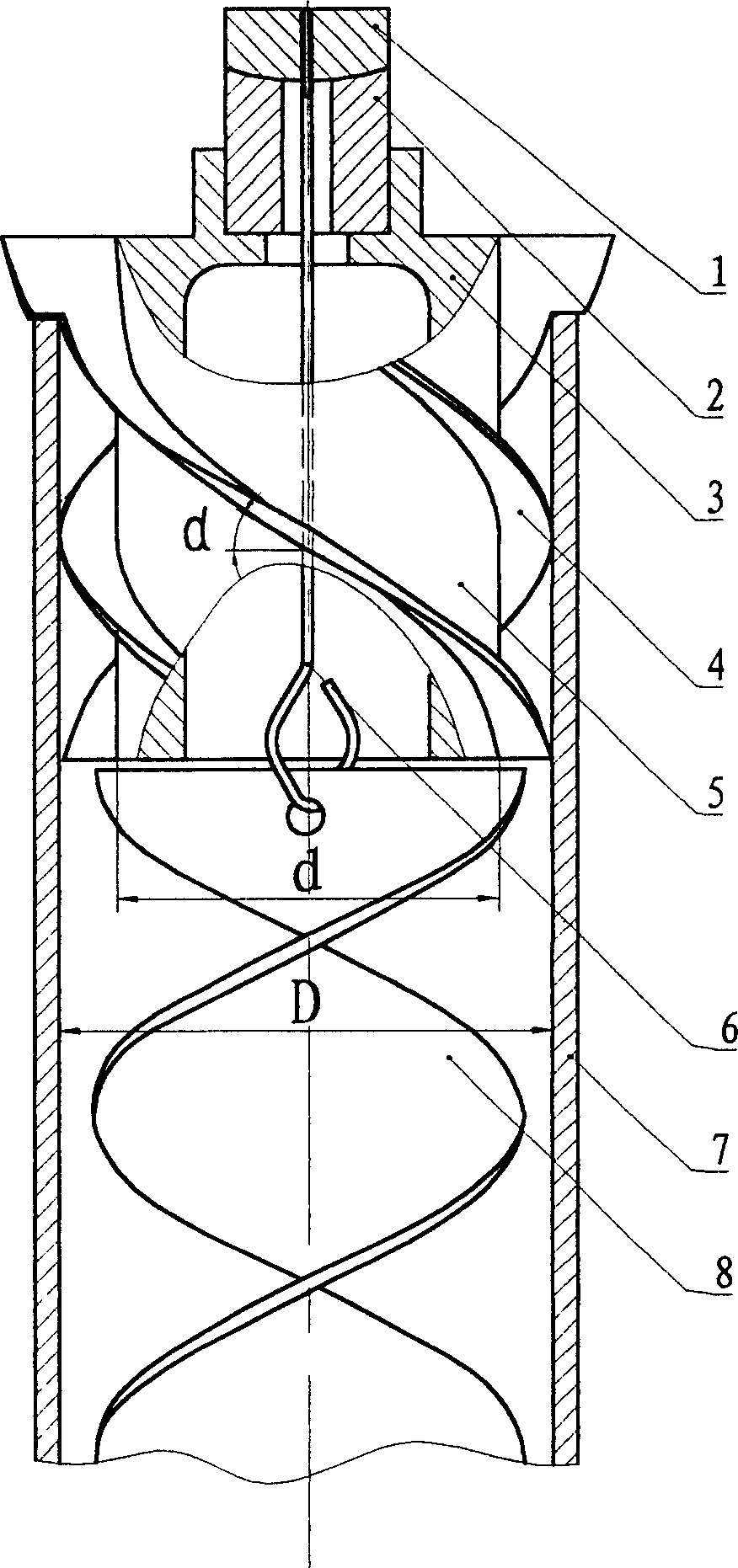

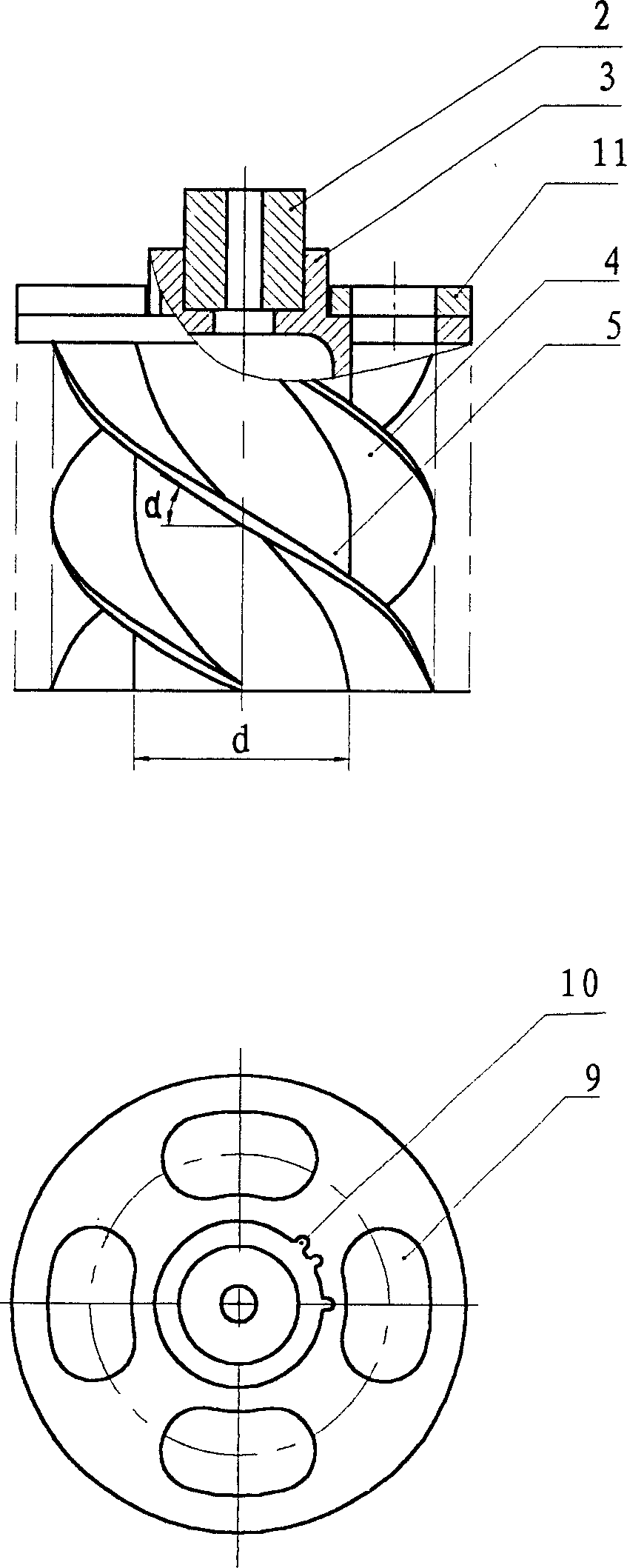

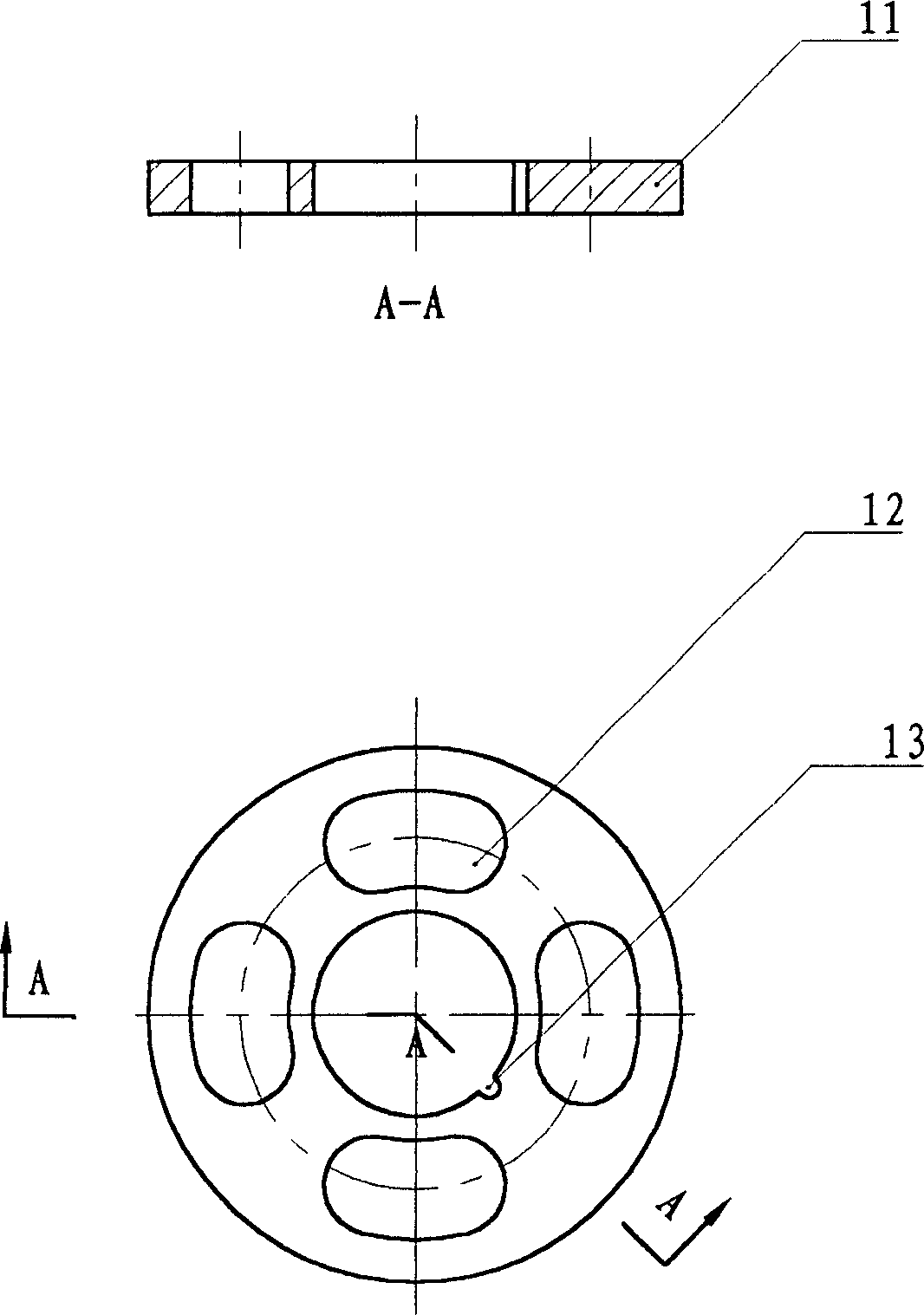

[0012] The specific embodiment of patent of the present invention is illustrated below in conjunction with accompanying drawing:

[0013] The axial positioning device of the rotary cleaning element in the heat transfer tube of the present invention is shown in figure 1 , the bearing seat 3 is installed at the inlet end of the heat transfer tube 7, and the bearing seat 3 is provided with a spiral deflector 4 and a wall-attached cylinder 5.

[0014] The helical direction of the deflector 4 is the same as that of the rotating cleaning element 8 (and opposite to that of the rotating cleaning element 8 ). The helix angle α of the deflector 4 is in the range of 20°∽60°. The preferred solution is that the lower the flow velocity in the pipe, the smaller the value of the helix angle, and the greater the flow velocity through the helical deflector 4 will be. The number of guide fins 4 is 1-6, and the preferred solution is that the larger the diameter of the heat transfer tube 7, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com