Automatic speed changer for car

A technology of automatic transmission and main transmission, applied in the direction of vehicle gearbox, transmission element, transmission device, etc., can solve the problems of high production cost, complicated control, and increase of control factors, and achieves reduction of vibration, simplification of control system, and reduction of factors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

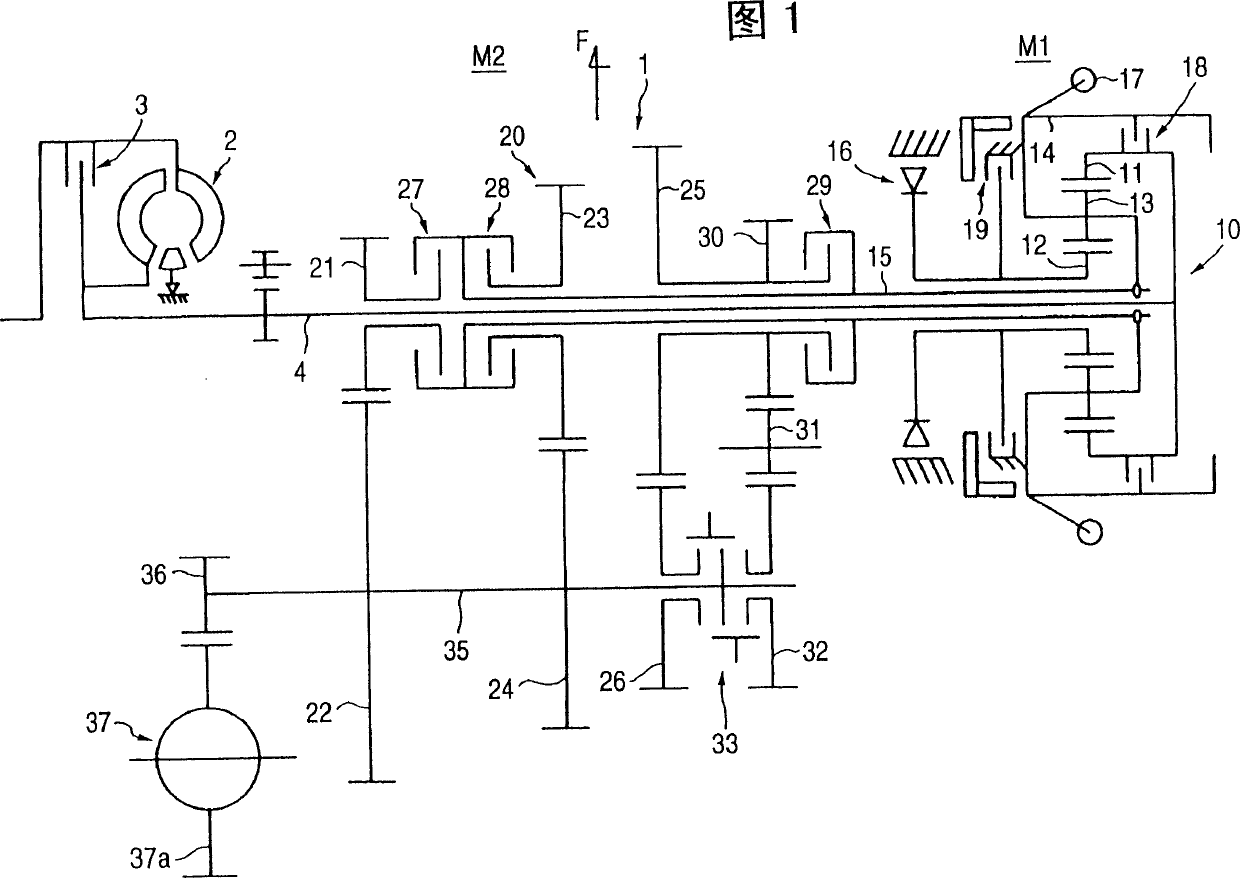

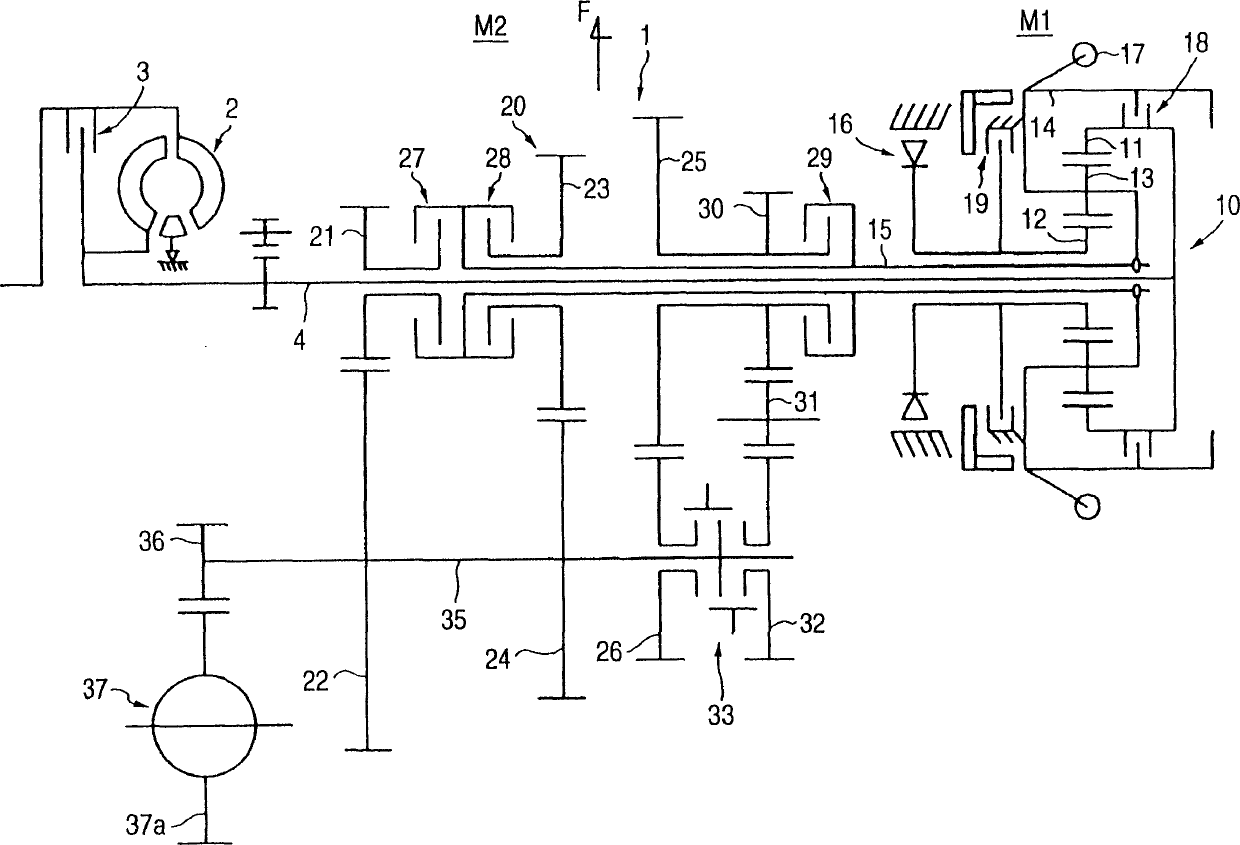

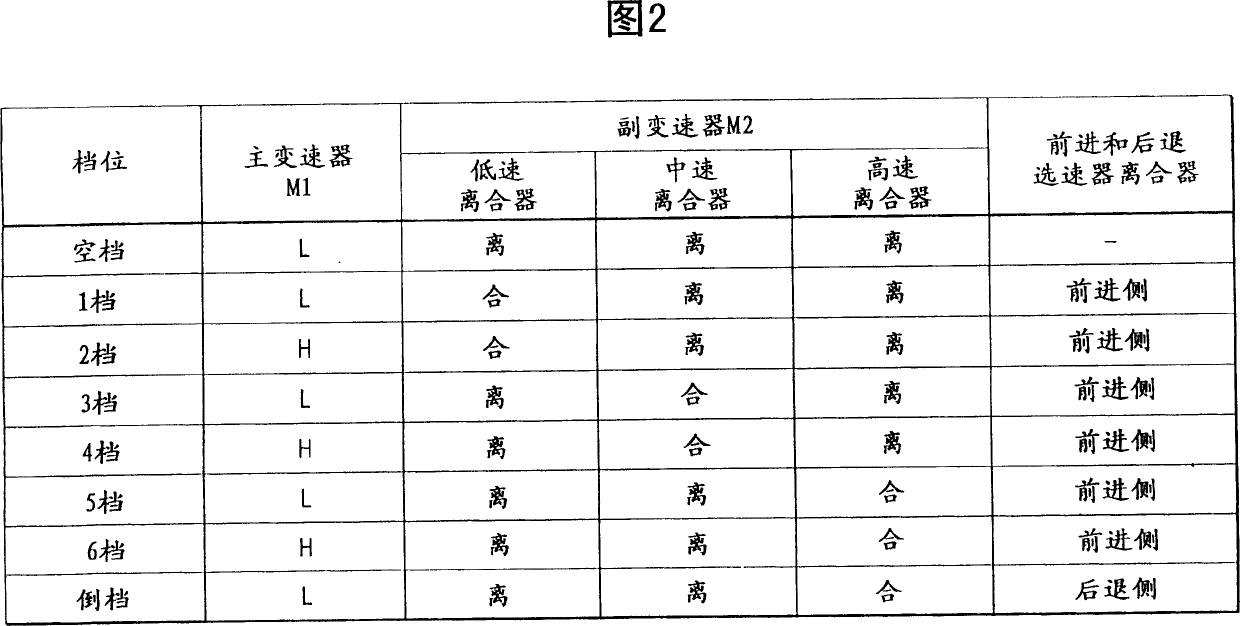

[0023] Referring to Figs. 1 to 4, a first embodiment according to the present invention will be described below.

[0024] Fig. 1 shows a schematic structural diagram of an automatic transmission 1 designed as a front-engine front-wheel drive (FF type vehicle) according to an embodiment of the present invention.

[0025] An internal combustion engine (not shown) is arranged transversely on the left-hand side of the front of the vehicle body, and its output is transferred to an input shaft 4 extending to the right side through a torque converter 2 and a lockup clutch 3 .

[0026] The input shaft 4 including a main shaft extends to the right by a certain length, and a planetary gear set 10 is provided at the right end of the thus extended input shaft 4 .

[0027] The planetary gear set 10 includes a ring gear 11, a sun gear 12 and planetary gears 13, all of which are helical gears. The ring gear 11 is integrally connected with the input shaft 4, and at the same time, includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com