Electric rotary shaver

A technology of electric rotation and razor, which is applied in metal processing and other directions, and can solve the problems of limited inclination angle and difficulty in increasing the inclination angle of the outer blade 22

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the electric rotary shaver of the present invention will be described in detail below with reference to the accompanying drawings.

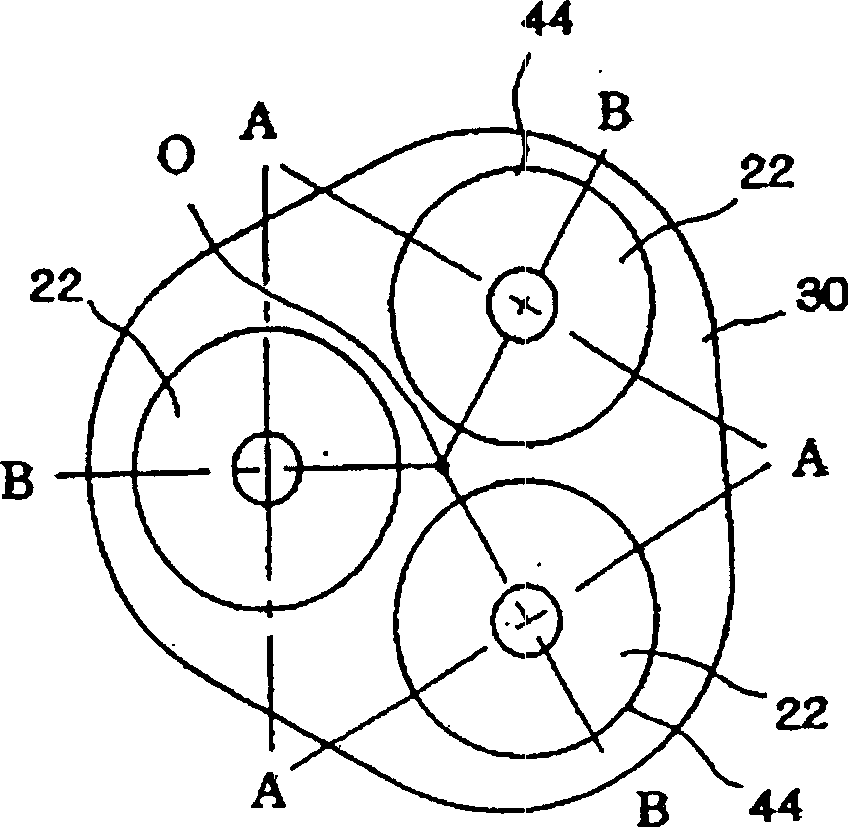

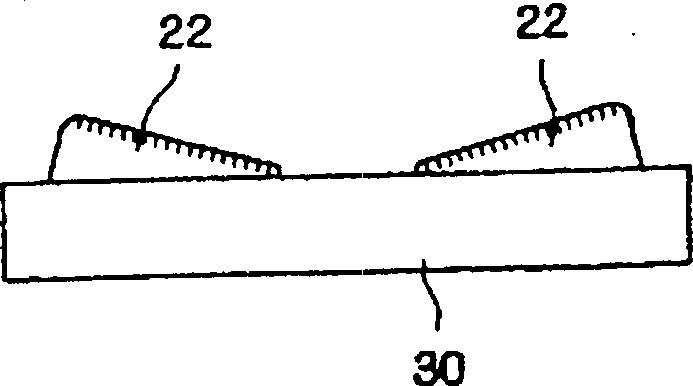

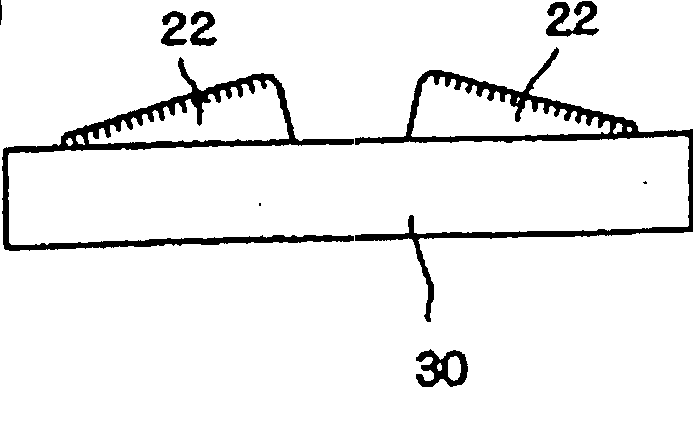

[0033] The electric rotary shaver of the present invention is characterized in that each outer blade 22 is supported by a pair of pivots arranged perpendicularly to each other, so that the outer blade 22 can be tilted in the outer blade hole 44 of the knife holder 30 .

[0034] figure 1 is a schematic diagram showing a supporting manner in which the outer blade 22 is pivotally supported in the blade holder 30 . Three outer blades 22 are positioned within the tool holder 30 such that the center of the outer blades 22 is located at the vertices of an equilateral triangle.

[0035]Positions A and B are where the pivots are arranged. The pivot axis for tiltably supporting each outer blade 22 is located on two imaginary lines passing through the center of each outer blade 22 and perpendicular to each other. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com