Laser measuring machine

A laser measurement and laser technology, applied in the field of laser measurement machines, can solve the problem of inability to obtain a large tilt range and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

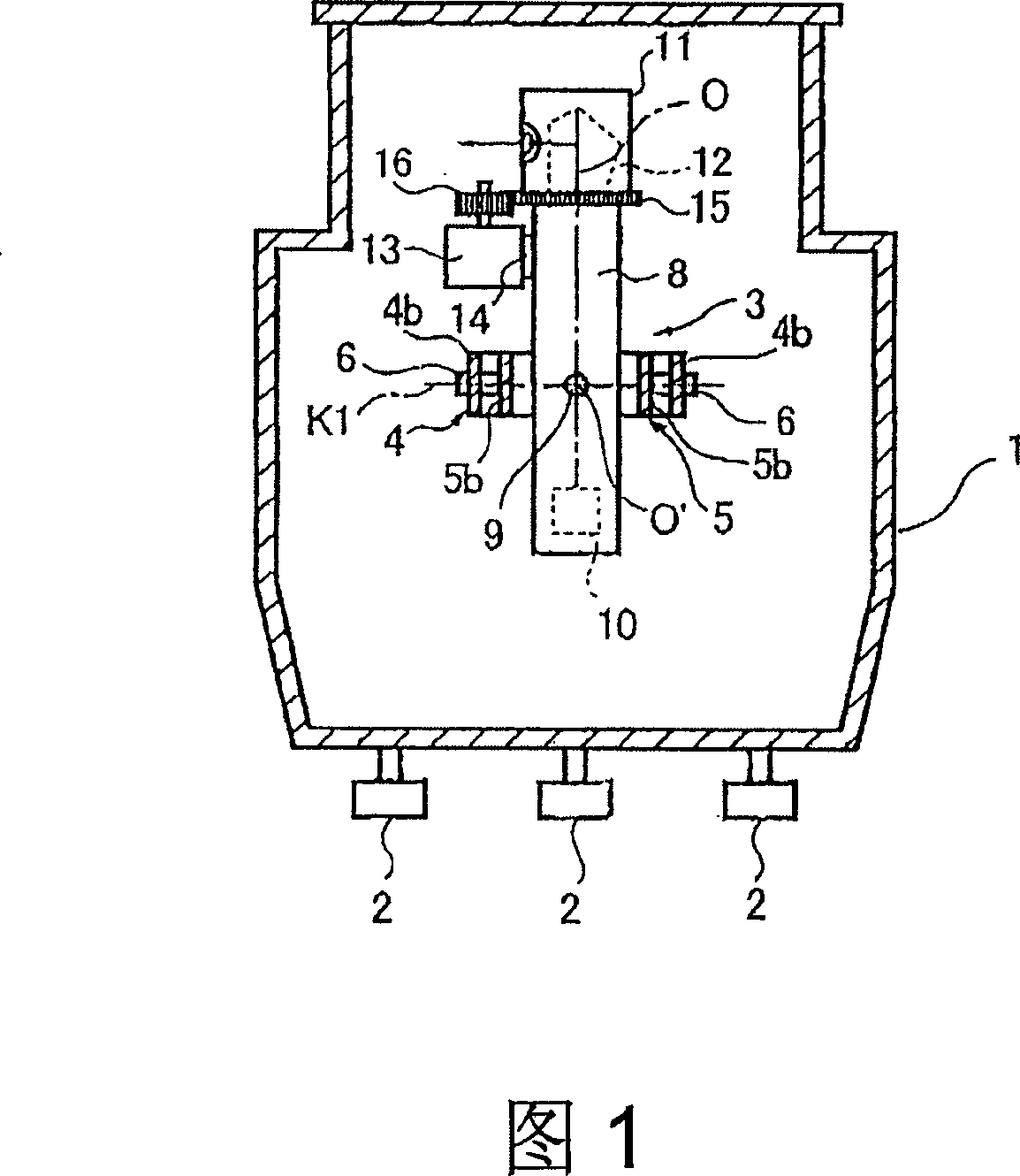

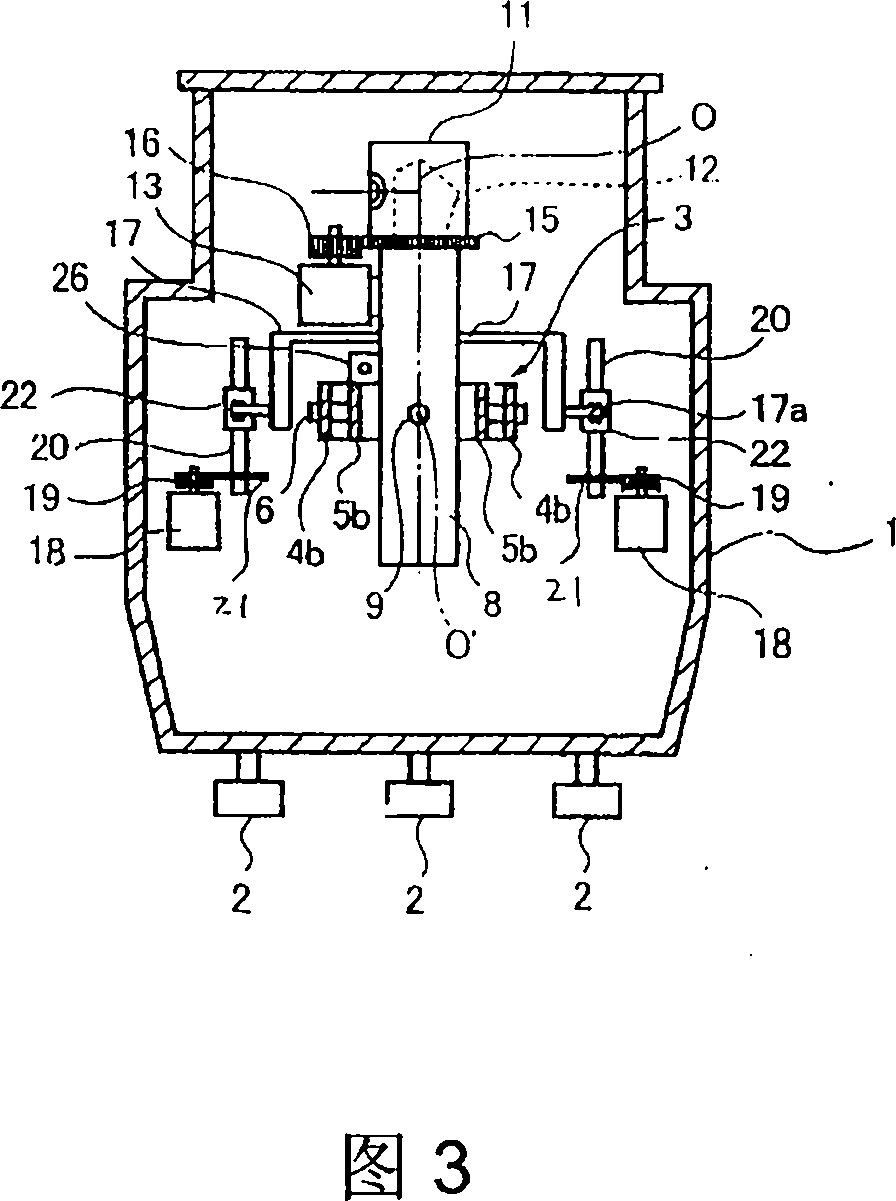

[0035] figure 1 Among them, 1 is the shell of the laser measuring machine. A calibration screw 2 is arranged on the lower part of the housing 1 . The calibration bolt 2 has the function of vertically calibrating the housing 1 .

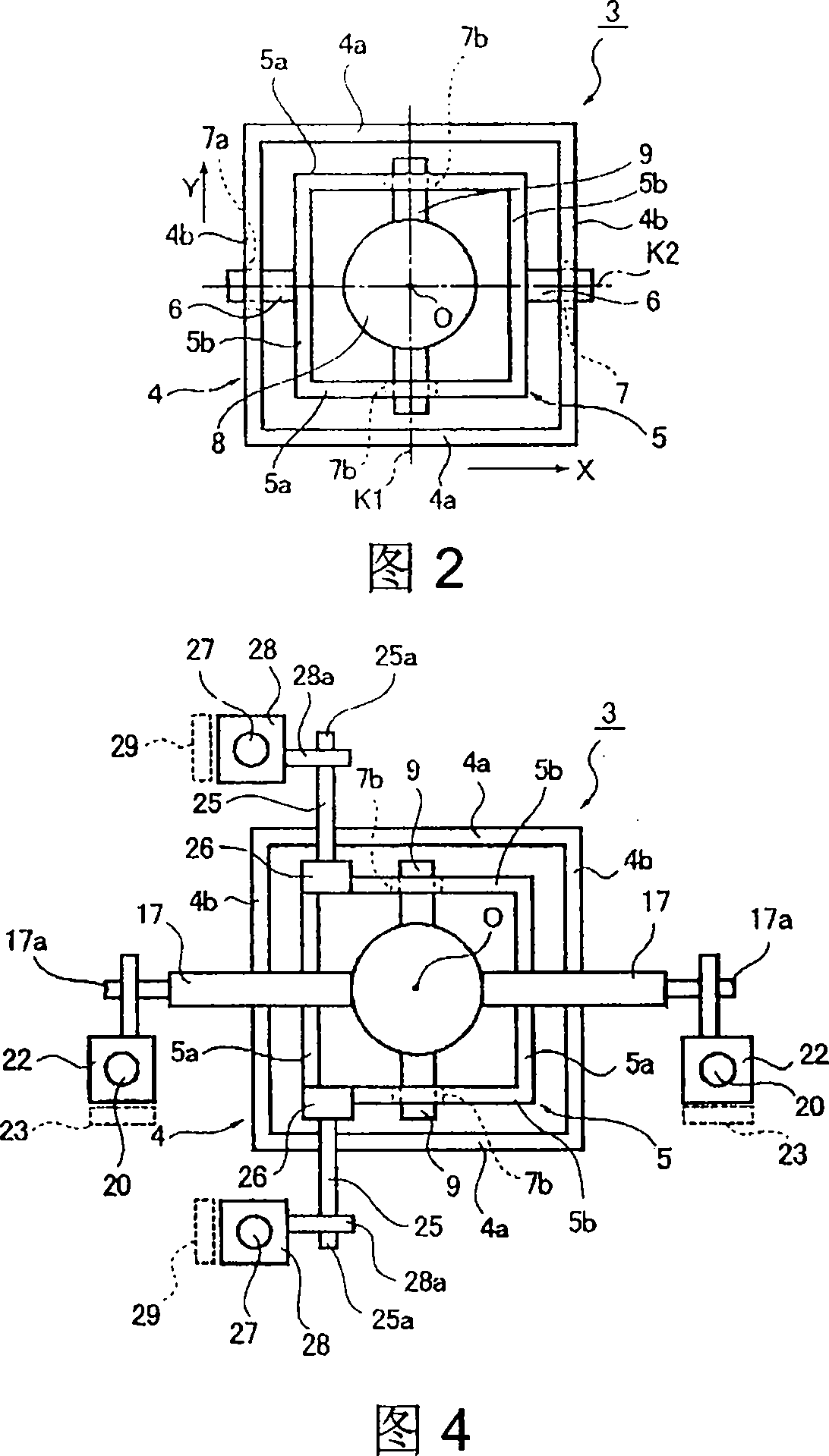

[0036] Inside this enclosure 1, as figure 2 As shown, a universal joint mechanism 3 is provided. Here, the universal joint mechanism 3 is composed of a rectangular outer frame 4 and a rectangular inner frame 5 surrounded by the outer frame 4 .

[0037] Such as figure 2 As shown, the outer frame 4 has a pair of parallel plates 4a, 4a extending along the X direction and a pair of parallel plates 4b, 4b extending along the Y direction. The outer frame 4 is fixed on the shell 1 . This inner frame 5 has a pair of parallel plates 5a, 5a extending in the X direction and a pair of parallel plates 5b, 5b extending in the Y direction.

[0038] On the pair of parallel plates 5b, 5b of the inner frame 5, a pair of shaft portions 6, 6 extending in opposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com