Modified silica-gel preparation process and use thereof

A silica gel and reaction technology, which is applied in the application field of compound filter additives, can solve the problems of disappearing efficiency and small exchange capacity, and achieve the effect of reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

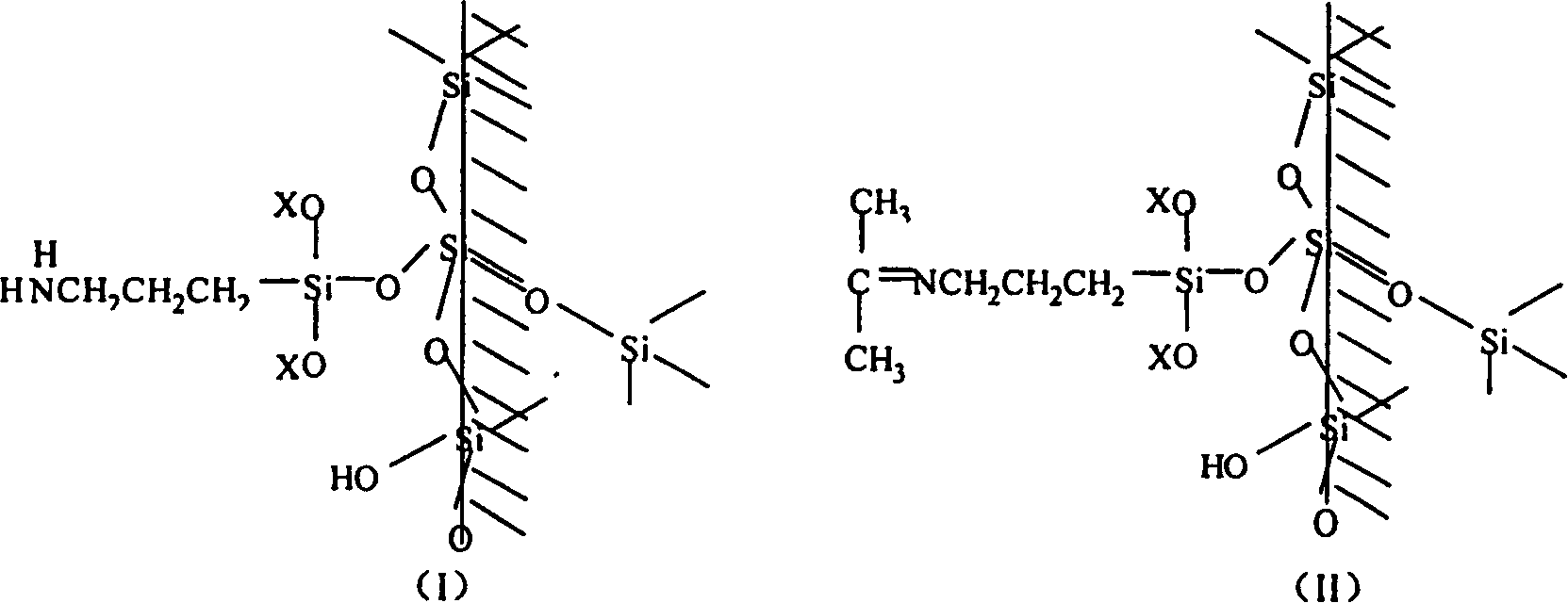

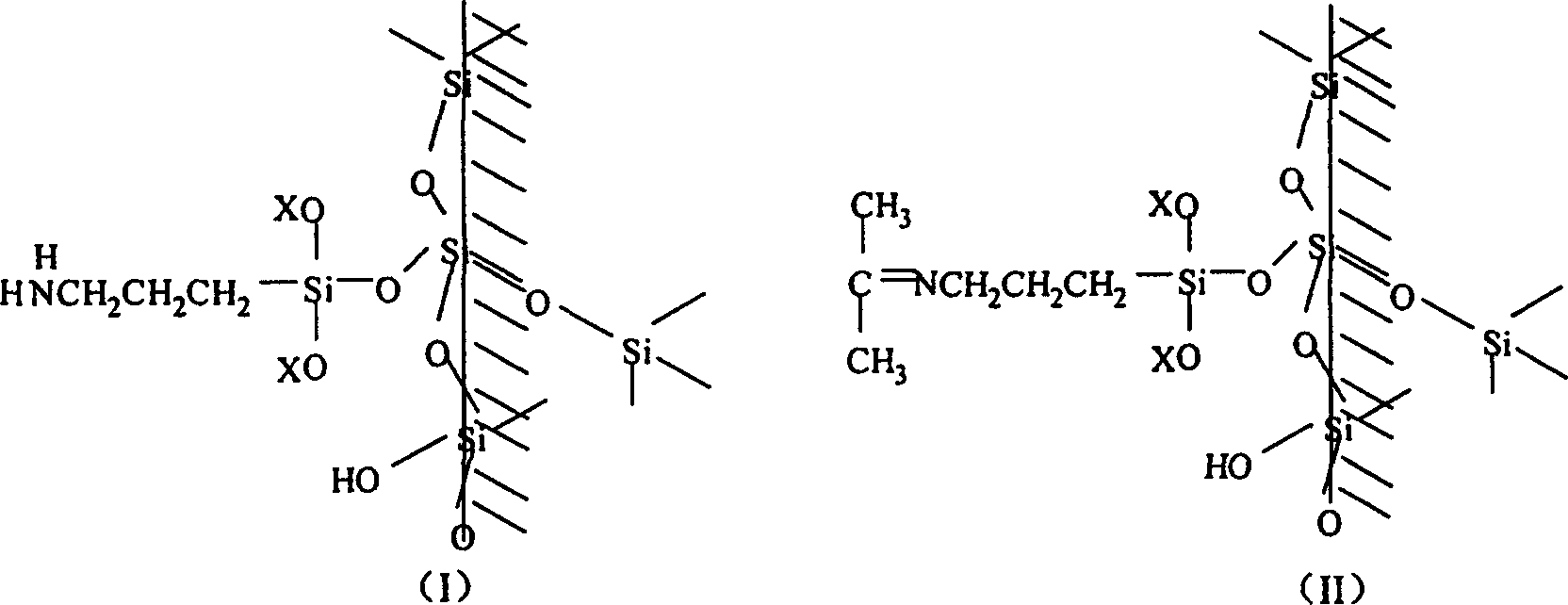

Method used

Image

Examples

Embodiment Construction

[0023] (1) Fully mix 500ml 3-aminopropyltriethoxysilane, namely KH550, and 5000ml acetone in a 20-liter plastic bucket, and let stand for 30 minutes;

[0024] (2) Take 2 kg of silica gel with a particle size of 60-80 mesh, put it in a 20-liter plastic bucket, fully mix it with the above reaction solution, and let the mixture stand at room temperature for 48 hours, shaking it occasionally;

[0025] (3) After the reaction is finished, filter and dry in the air, and then dry at 90-100°C for 48 hours;

[0026] (4) After collection, put it into a sample bag for subsequent use;

[0027] (5) The obtained sample is made into a composite tip stick, and then prepared into a filter cigarette.

[0028] (6) After the obtained cigarette is balanced, carry out the test of relevant items.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com