Radiator integral pressure measuring device

A technology of pressure measuring device and radiator, which is applied in the direction of using liquid/vacuum to measure liquid tightness and measuring the rate of increase and deceleration of fluid, etc. It can solve the problems of high work intensity, troublesome disassembly and assembly, and inconvenient testing. Achieve the effect of reducing labor intensity and good inspection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

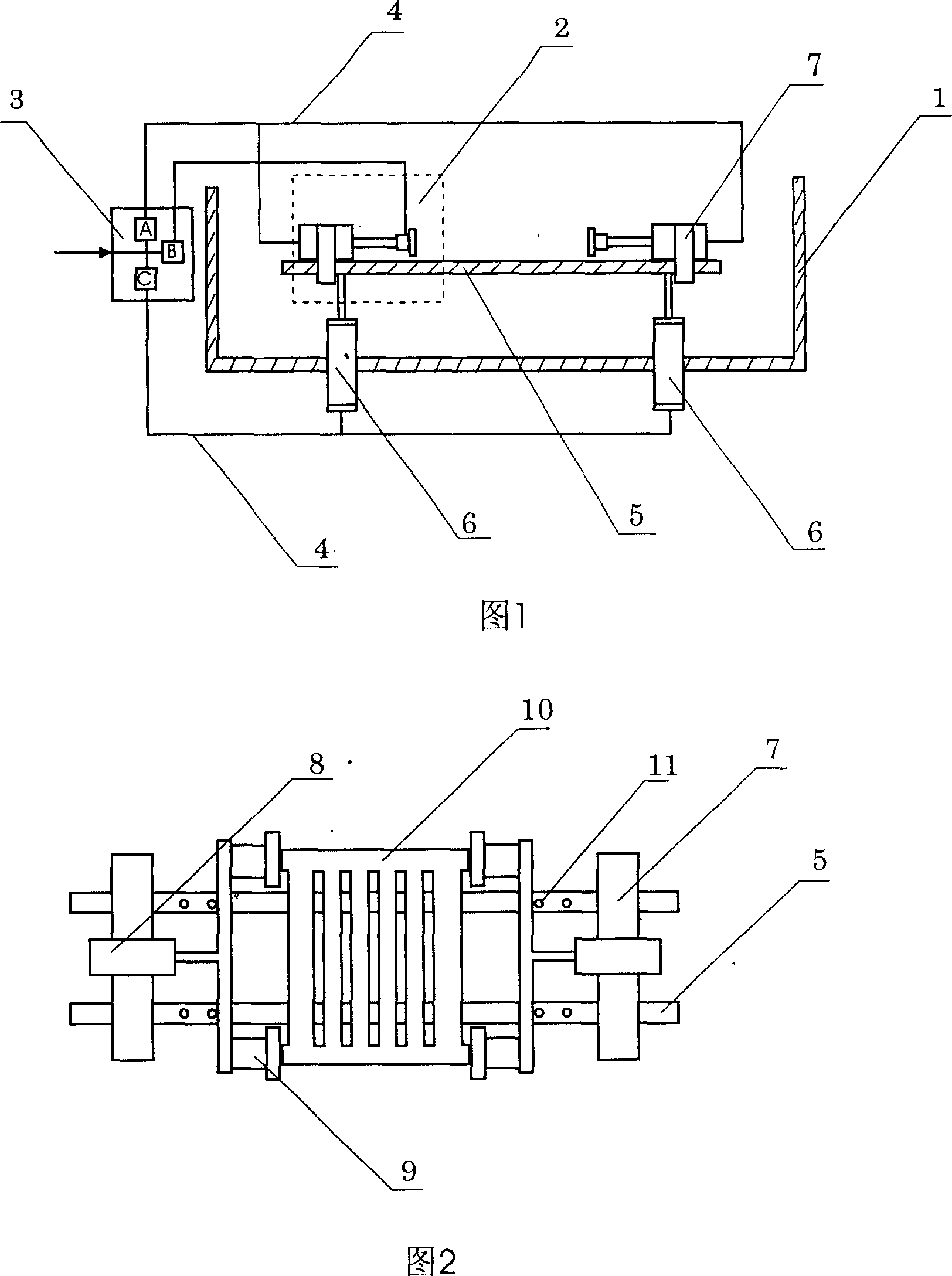

[0014] As can be seen from Fig. 1, the present invention comprises water tank 1, landing gear, clamping device 2, power unit, and described landing gear comprises two lifting cylinders 6 and two parallel support plates 5, and two parallel support plates 5 and two lifting The piston of the cylinder 6 is connected as a whole, and the lifting cylinder 6 is sub-packed on the two ends of the support plate 5 . The cylinder body of the lifting cylinder 6 runs through the bottom of the water tank 1 and is tightly connected with the water tank 1 to ensure that the water in the water tank 1 will not leak. The cylinder body of the lifting cylinder 6 is connected with the power air source. When the air source is turned on, the 6 pistons in the lifting cylinder are lifted up, and at the same time, the support plate 5 rises together. When the air source is turned off, the support plate 5 returns to its original state driven by the piston. Location.

[0015] The power device includes an air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com