Luminous container for high voltage discharge lamp

A technology for high-pressure discharge lamps and containers, which is applied to parts of high-pressure discharge lamps and gas discharge lamps, and can solve problems such as unreasonable and complicated steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments embodying the present invention will be described below with reference to the drawings.

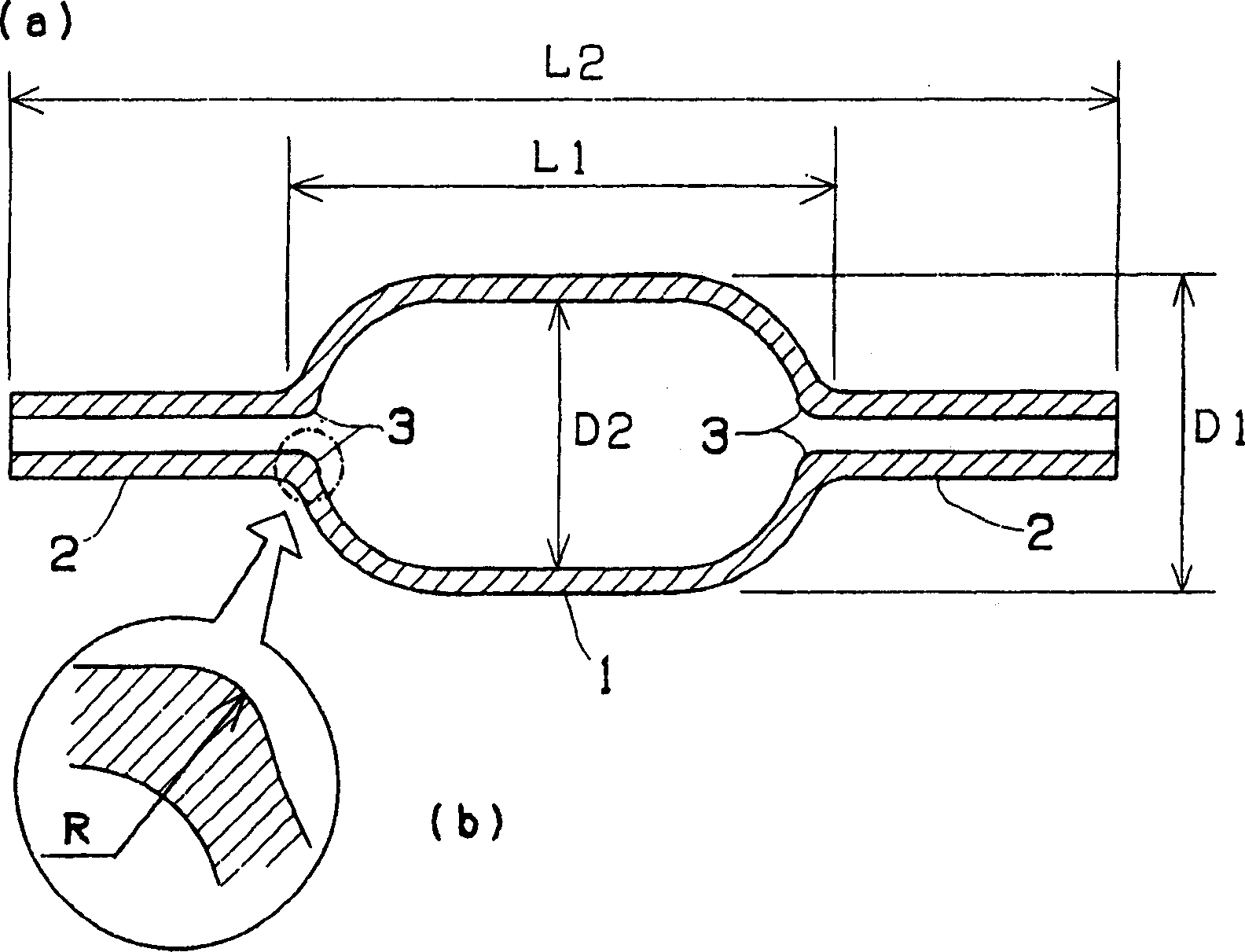

[0019] figure 1 It is a cross-sectional explanatory view showing one embodiment of a light-emitting container for a high-pressure discharge lamp according to the present invention. It has a case 1 having an enlarged diameter and an approximately elliptical shape forming a discharge space in the center. Small diameter capillary part 2. A rod-shaped current conductor (not shown) provided with a discharge electrode is inserted into the tip of the capillary portion 2, and the conductor is sealed and fixed.

[0020] The luminescent vessel is molded by adding alumina as a main component, adding, for example, MgO to the filler, and is formed so as to have translucency after sintering. As an example showing the dimensions of each part, the outer diameter D1 of the casing 1 is 14.8 mm, the inner diameter D2 is 13.0 mm, the length L1 is 25.5 mm, and the total length L2 of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap