Ancient wood furniture and manufacturing method thereof

A production method and technology of wood furniture, applied in the direction of wood processing equipment, wood treatment, manufacturing tools, etc., to achieve the effect of clear wood grain, easy operation, novel and unique technological process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

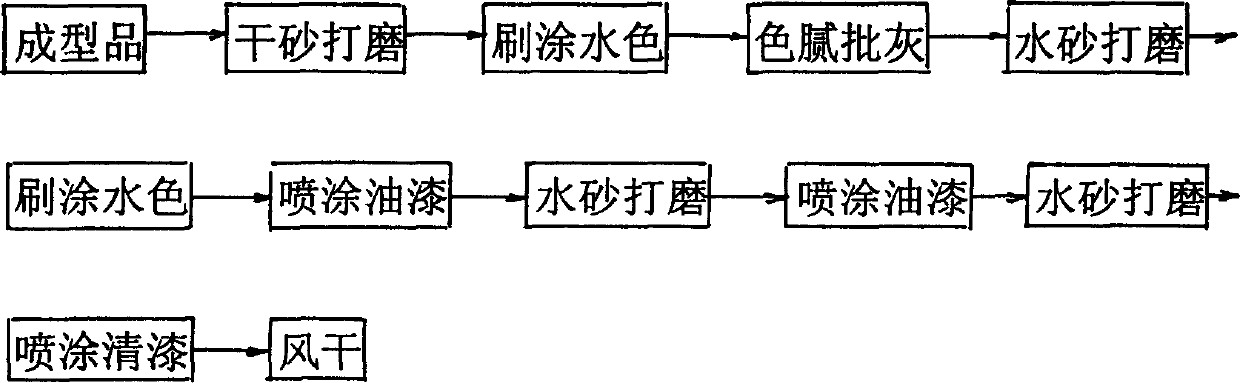

Method used

Image

Examples

Embodiment 1

[0018] see figure 2 The present invention can choose ordinary pine, Chinese fir and other woods as raw materials, and carry out open flame carbonization to the dried wood or molded products, that is, to carbonize the surface of wood or molded products through an open flame. Moving in the direction of the wood grain, the woody part of the wood or molded product is carbonized and dented, while the wood tendons protrude relative to the woody part because of its hardness. Then clean the dust and clean the surface, if you can use a brush to brush off the dust, so that the surface of the product will naturally form the main color of ancient wood with dark coffee tone.

[0019] After surface cleaning, the wood texture on the surface of the furniture is clear, and there is an obvious concave-convex three-dimensional effect when touched by hands. The depth of the concave-convex is 0.2-1.5 mm. The production of this product does not pollute the environment and is a green environmental...

Embodiment 2

[0021] see image 3 , Carry out open flame carbonization of molded products. The so-called open flame carbonization can be a mixture of oxygen and liquefied gas (or acetylene or coal gas or biogas). At about mm, move the special oxygen cutting tool along the direction of the wood grain, the effective width of the instantaneous overfire is about 15-20 mm, and the carbonization (concave-convex) depth is 0.2-1.5 mm, the best is about 0.5 mm; in this process It only takes about 7 minutes to carbonize wood per square meter. Then carry out dust removal and clean surface. After the surface layer of the product is carbonized, use a brush (copper wire brush in this embodiment) to brush dust along the wood grain direction. After brushing, use a damp cloth to wipe off the remaining gray stains. There is an obvious concave-convex three-dimensional effect when touched by hand: this process only takes about 5 minutes per square meter of wood surface. After carbonization and surface cleani...

Embodiment 3

[0023] see Figure 4 , the molded product is carried out open flame carbonization, and then carry out dust-cleaning clean surface, these two steps are identical with embodiment two. After cleaning the surface, the varnish can be sprayed directly according to the customer's requirements; the varnish can be sprayed once or several times, with an interval of about 3 hours, and the surface effect can be bright or matte. Finally, the final product is formed after mechanical drying or natural air drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com