Coating device

A coating device and coating technology are applied in the direction of devices and coatings for coating liquid on the surface, which can solve the problems of difficulty in uniformly controlling the thickness of the coating and increased friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the coating apparatus of the present invention are described below with reference to the drawings. Although the present invention relates to a coating apparatus for uniformly coating the surface of flexible belt supports such as films and sheets running in one direction with a coating agent to form a thin coating, the specific structural and operational details disclosed herein are representative only. nature and do not limit the scope of the present invention.

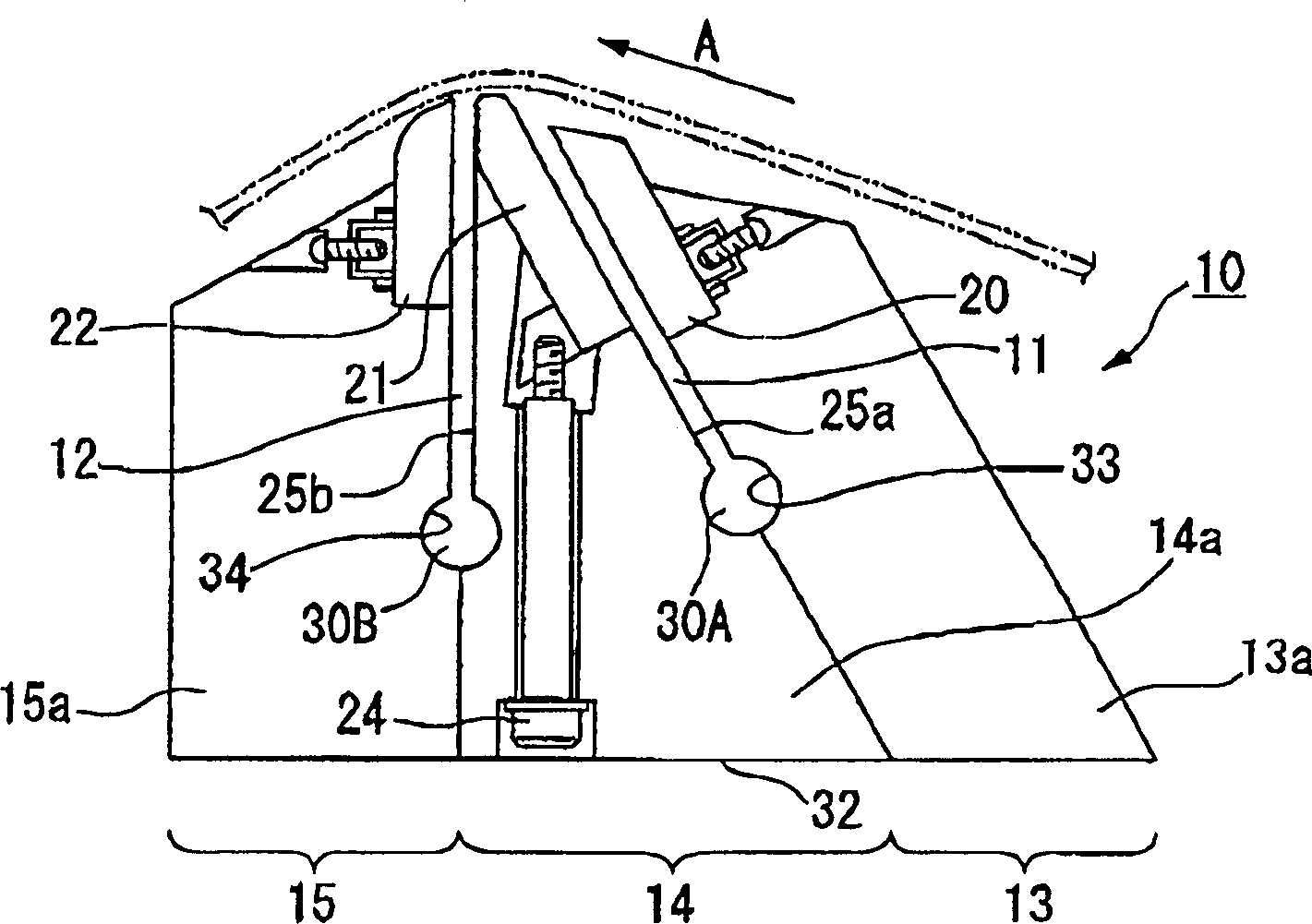

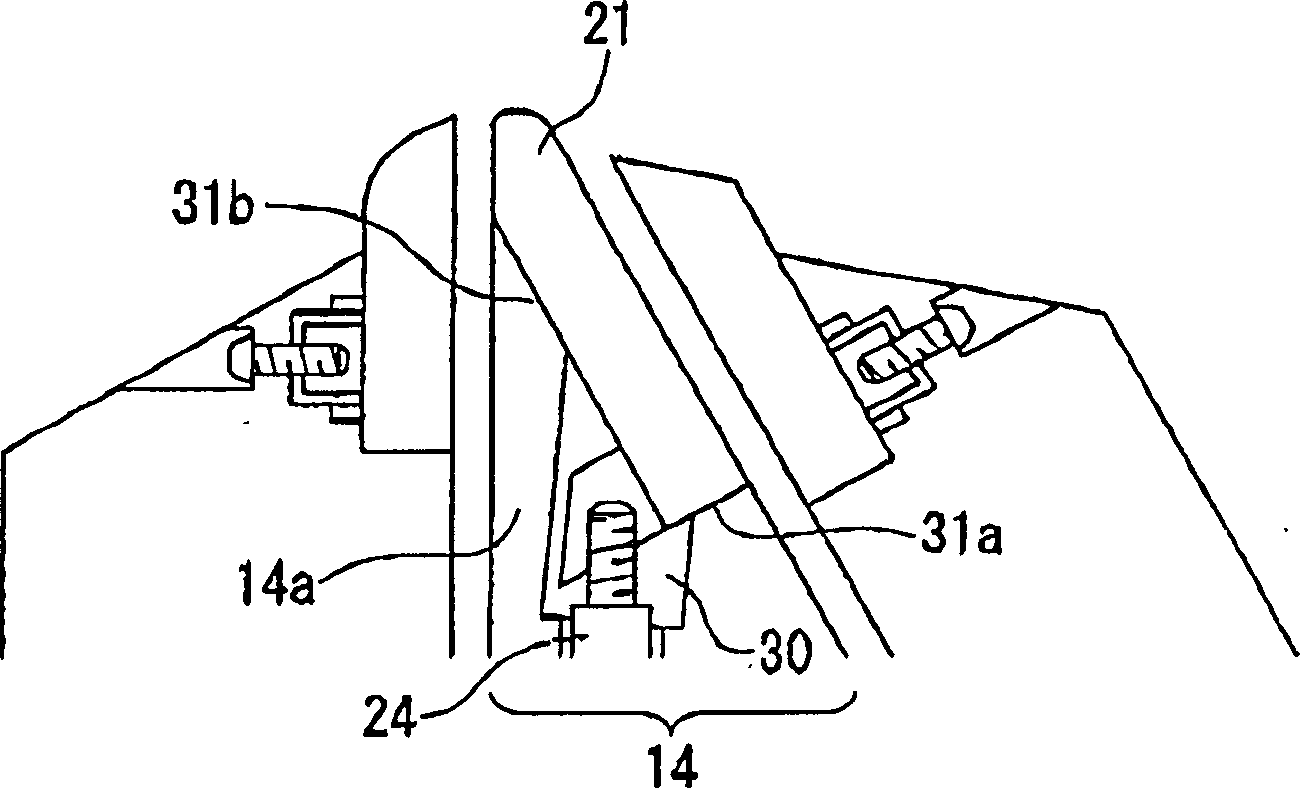

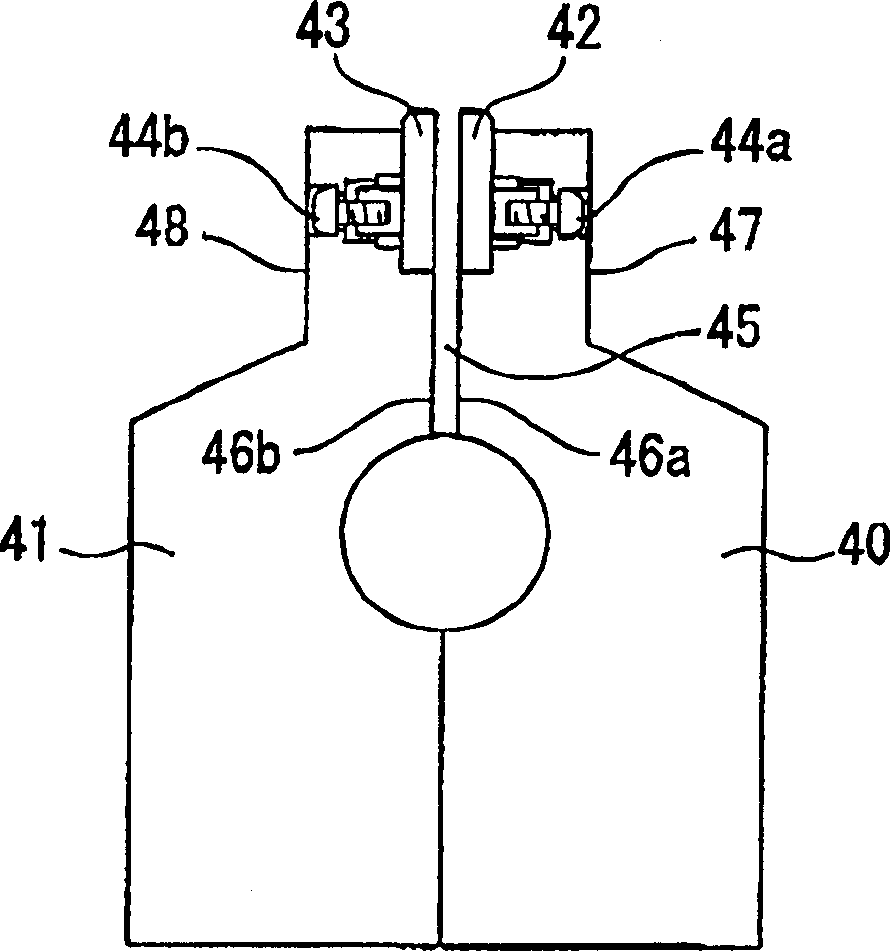

[0028] An embodiment of the coating device of the present invention is in figure 1 shown in . exist figure 1 , the coating device has a coating head 10 . In the coating head 10 , the first groove 11 is located between the first edge unit 13 and the second edge unit 14 , and the second groove 12 is located between the second edge unit 14 and the third edge unit 15 . The first, second and third edge units 13, 14 and 15 are arranged in this order in the running direction of the flexible belt s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com