Elastically deformable truck bed hopper for mining dump truck

A technology of elastic deformation and hopper, applied in the field of hopper frame, can solve problems such as increase in total weight, and achieve the effect of reducing quantity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] During normal mining operations, when loading or unloading raw materials, hoppers are gradually worn and torn due to friction, abrasion and similar mechanical phenomena. In the hopper of the invention, the materials and arrangement of the hopper used allow increased elastic deformation and higher impact resistance. Furthermore, with the present invention, when the hopper wears and teares, the weight of the hopper is reduced and parts thereof can be easily removed.

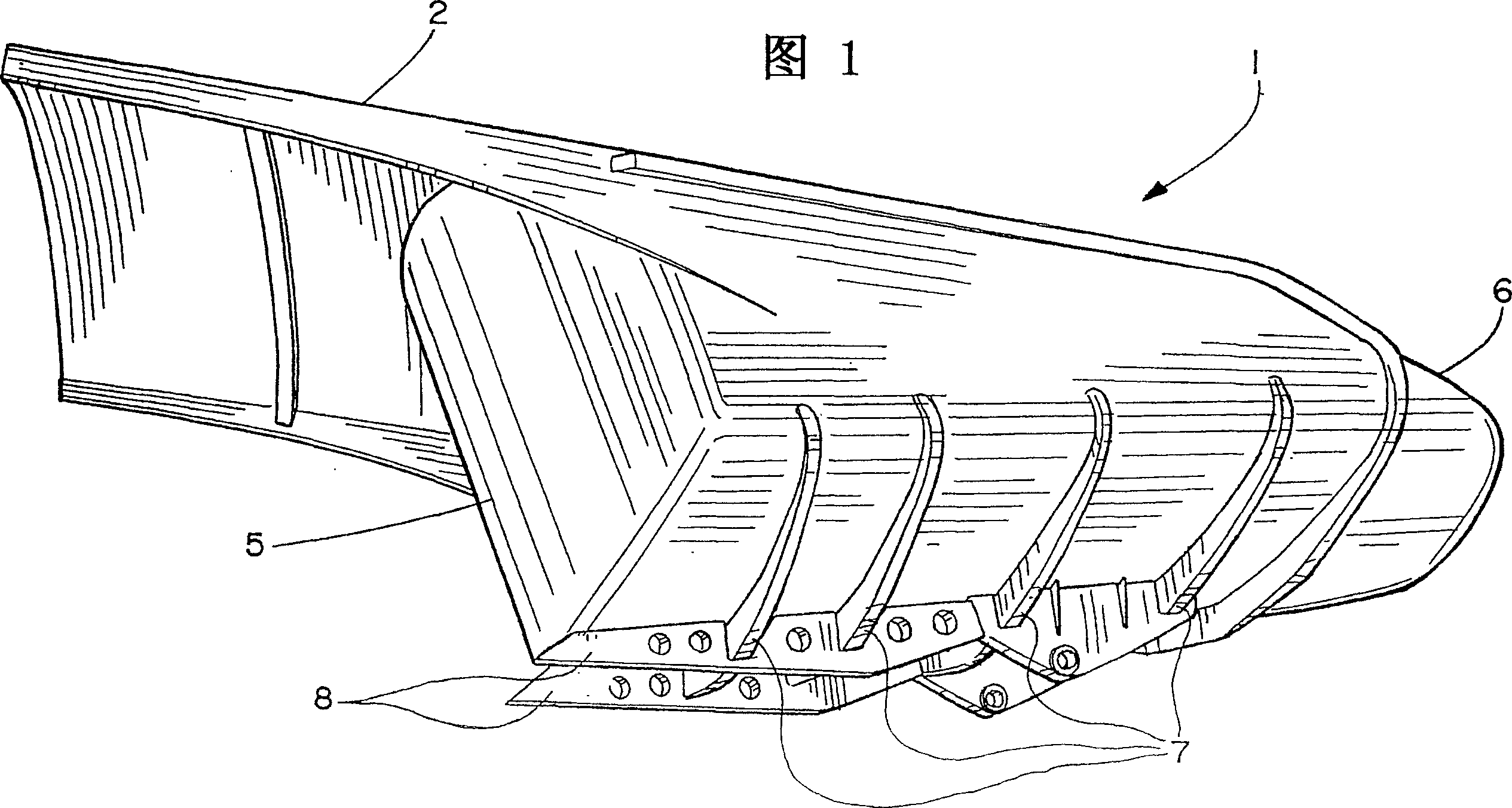

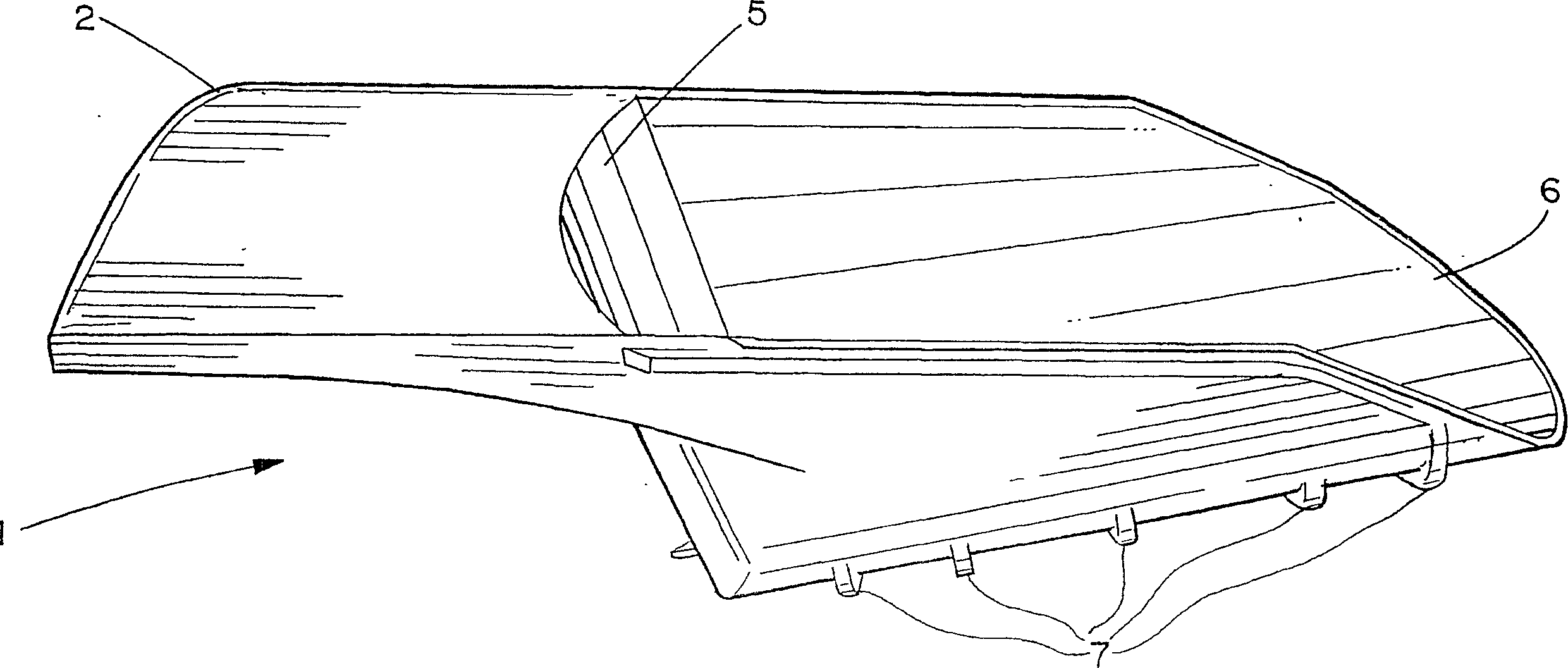

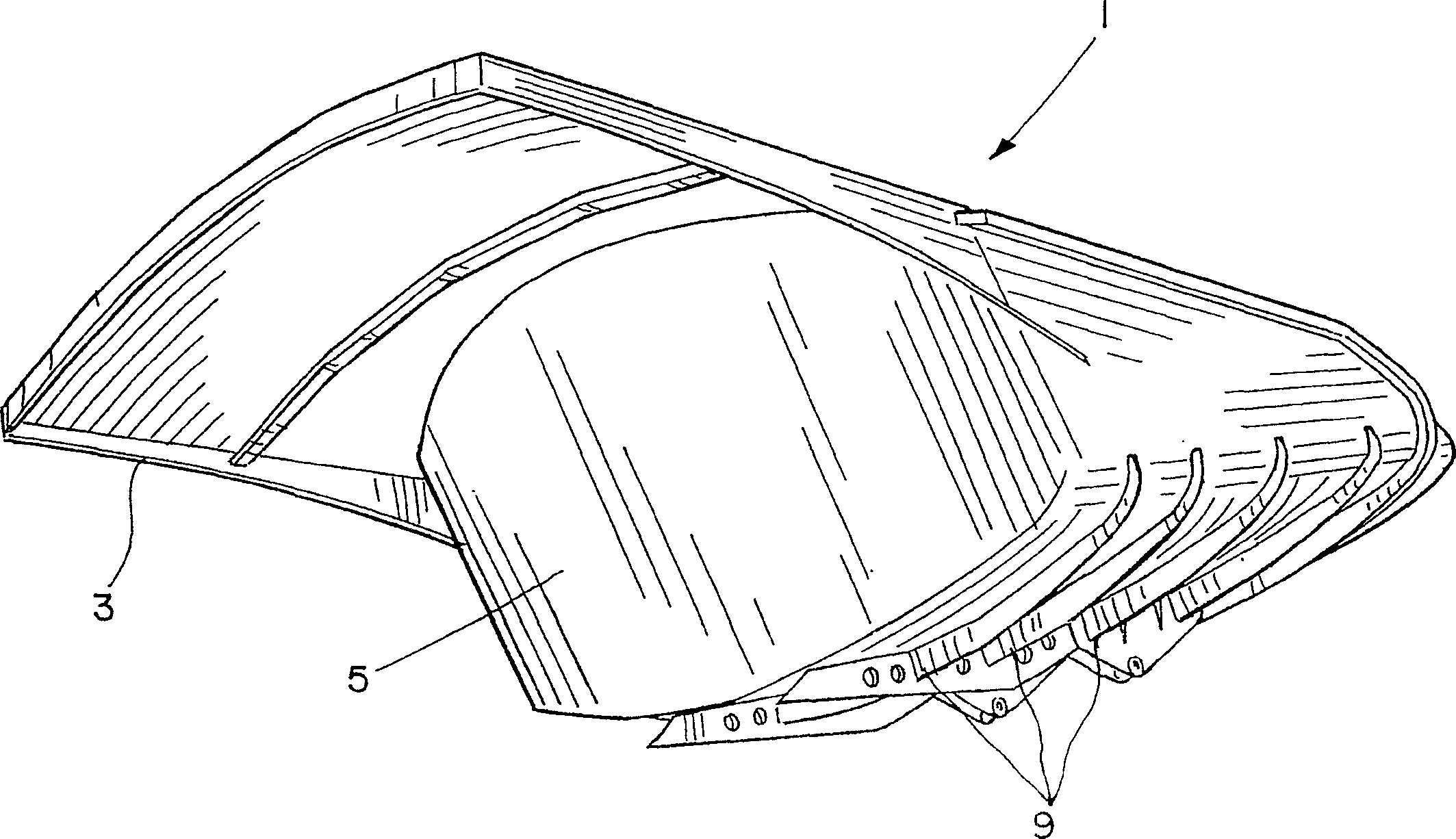

[0030] Referring to the accompanying drawings, numeral 1 denotes a mining hopper of the present invention, the hopper is preferably made of structural steel or wear and tear steel, and the hopper is obtained by producing a curved form with the structural steel or wear and tear steel Structure. That is, the arrangement of materials produces not a flat surface, but a curved surface.

[0031] From Figures 1-3 and Figure 6 , it can be observed that, preferably, the protective seam cover (2) of the hopper (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com