Bearing device

A technology of bearing device and bearing part, which is applied in the field of bearing devices, can solve problems such as difficulties, reduced rotation accuracy, and cost reduction, and achieve the effect of sufficient bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Hereinafter, embodiments of the present invention will be described based on the drawings.

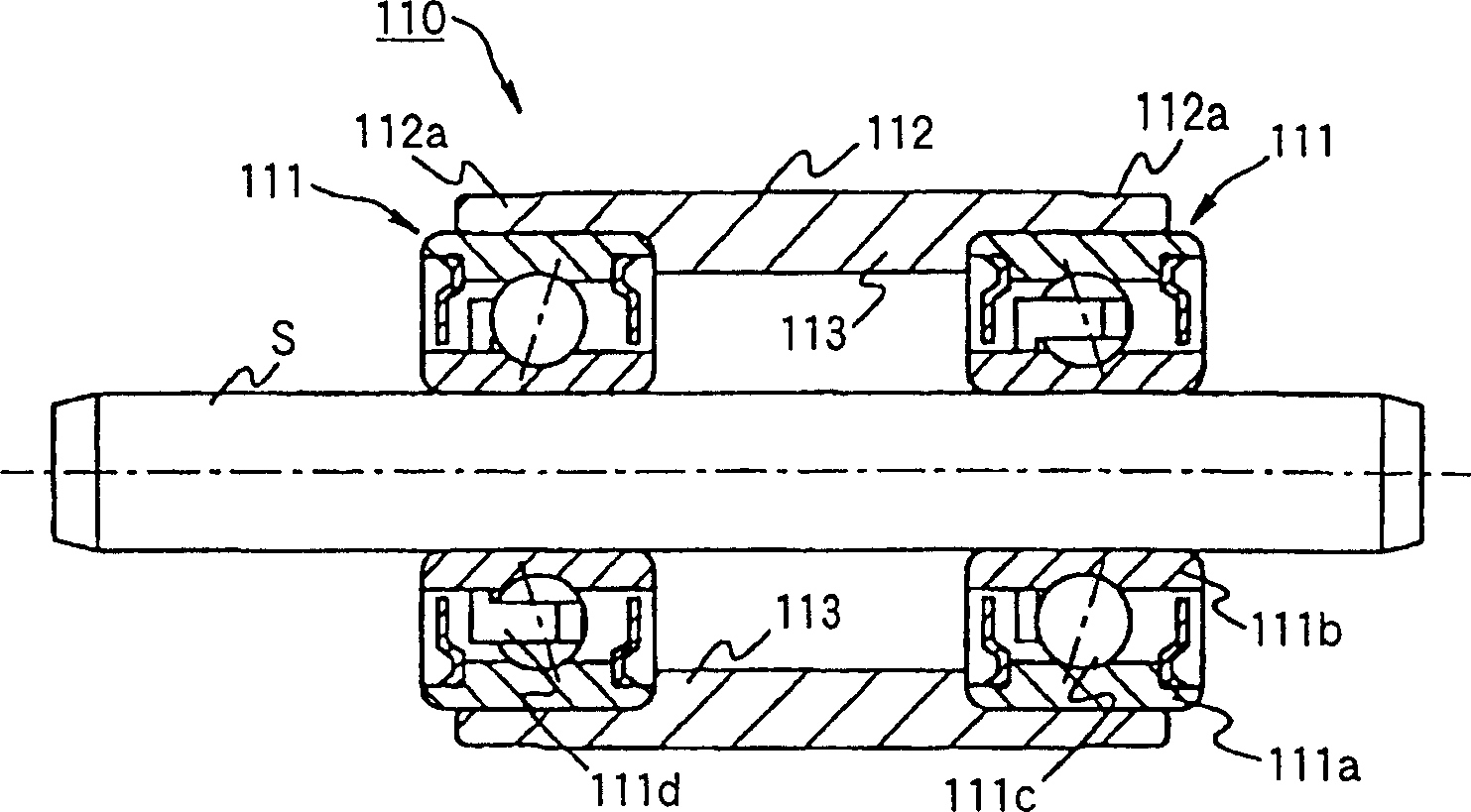

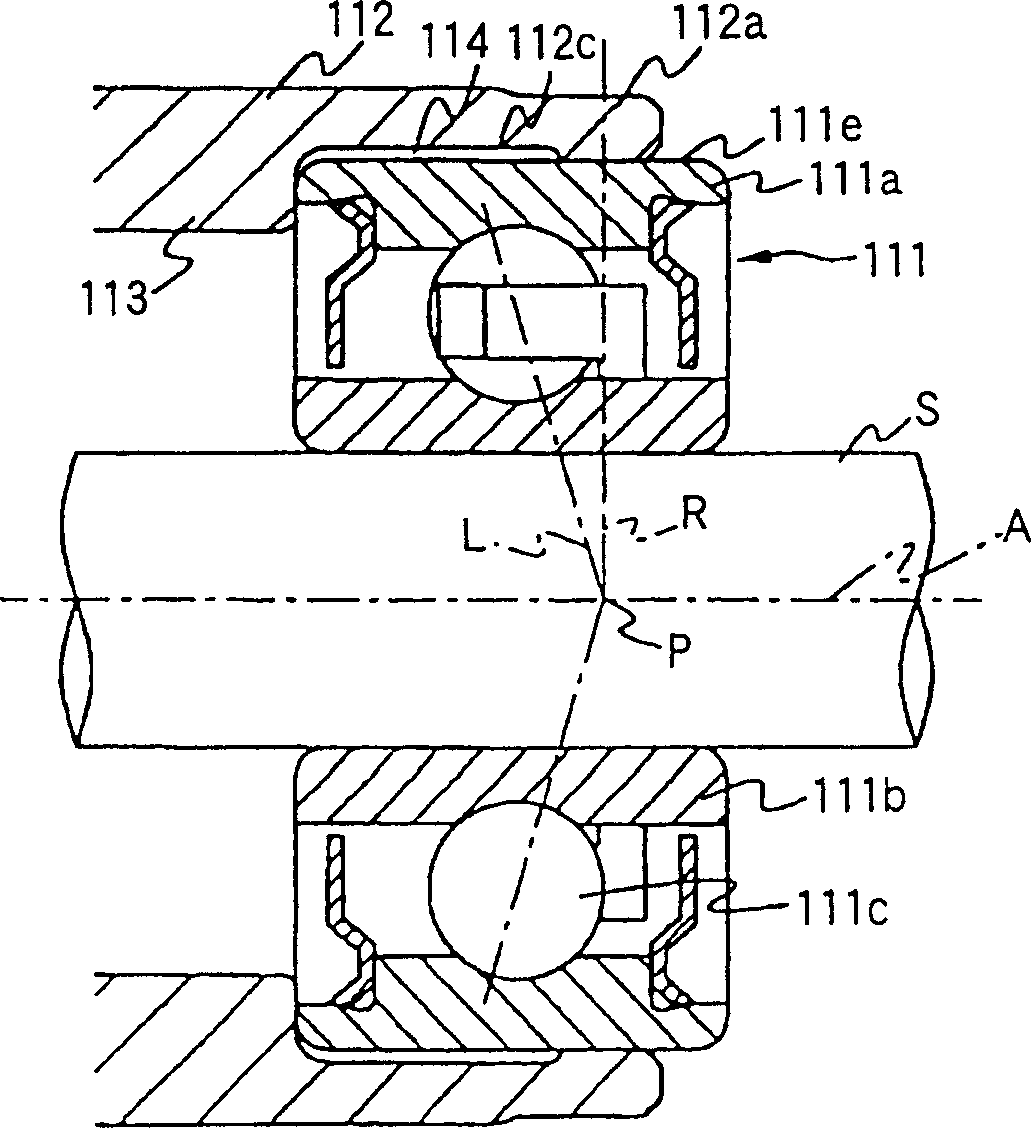

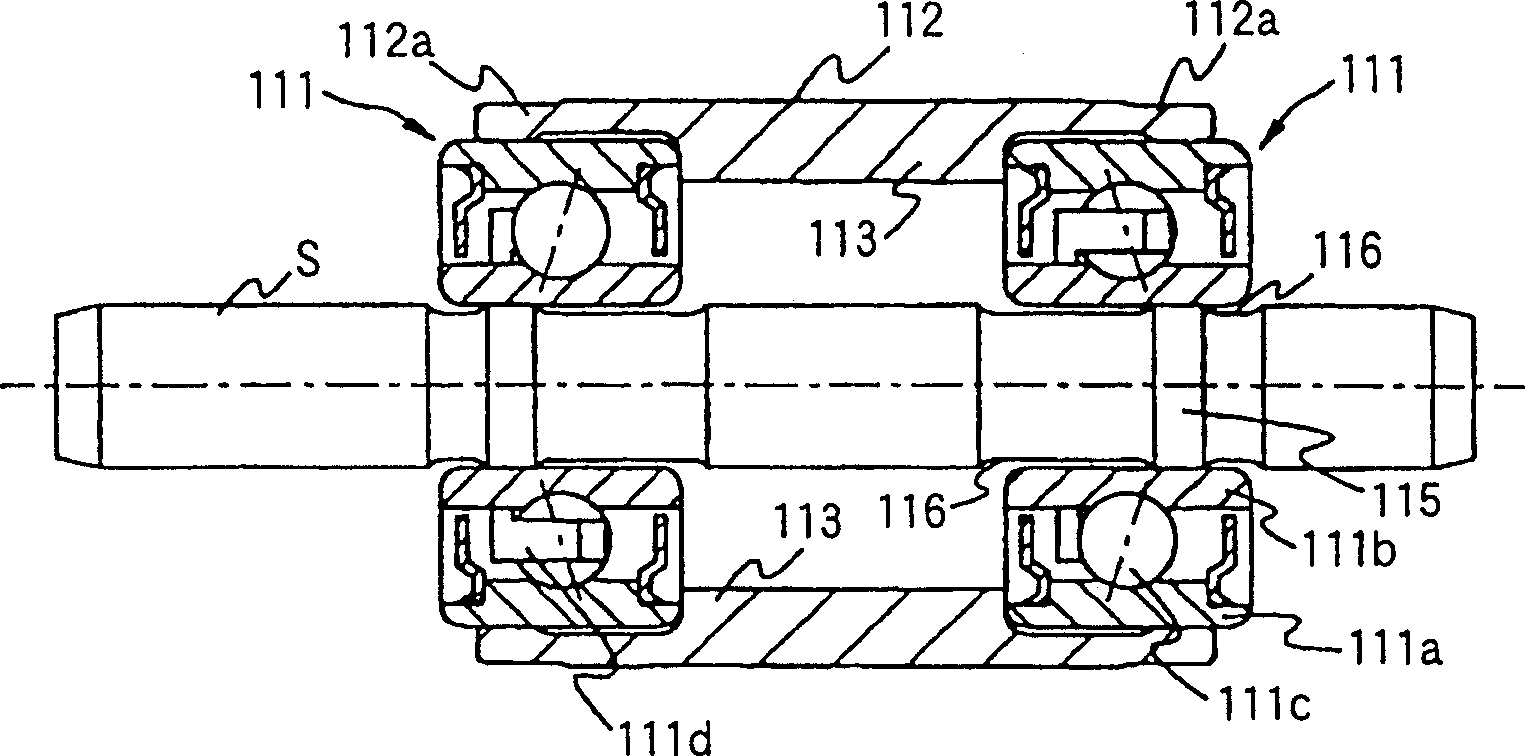

[0090] figure 1 It is an axial sectional view of the bearing device according to the first embodiment of the present invention, figure 2 It is a sectional view showing the main part of the bearing device related to the same embodiment. figure 1 Among them, the bearing device 110 is composed of a pair of deep groove ball bearings 111, 111 supporting the main shaft (shaft) S of the main engine, and a cylindrical housing 112 supporting the ball bearings 111, 111 on the same axis.

[0091] The housing 112 has an inner surface tightly fitted with the outer diameter surface of the rolling bearing 111, and on the inner surface of the housing 112, a figure 2 The stepped portion 113 is shown. The ball bearing 111 is composed of an outer ring 111a, an inner ring 111b, a rotating body 111c, a cage 111d, and the like.

[0092] The fitting parts 112a, 112a of the housing 112 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com