Rubber roller hulling separator

A technology of rubber rollers and shelling machines, which is applied in grain shelling, grain processing, application, etc., and can solve the problem of expensive tracking devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

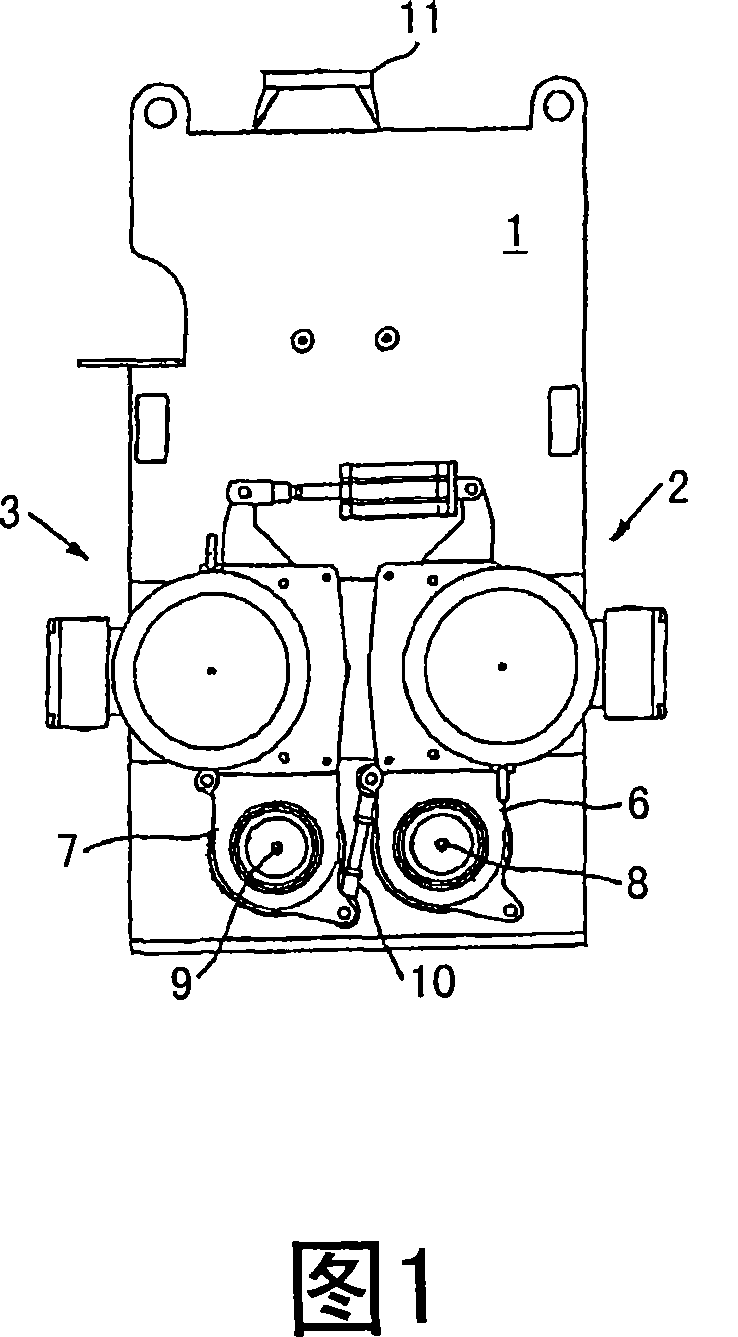

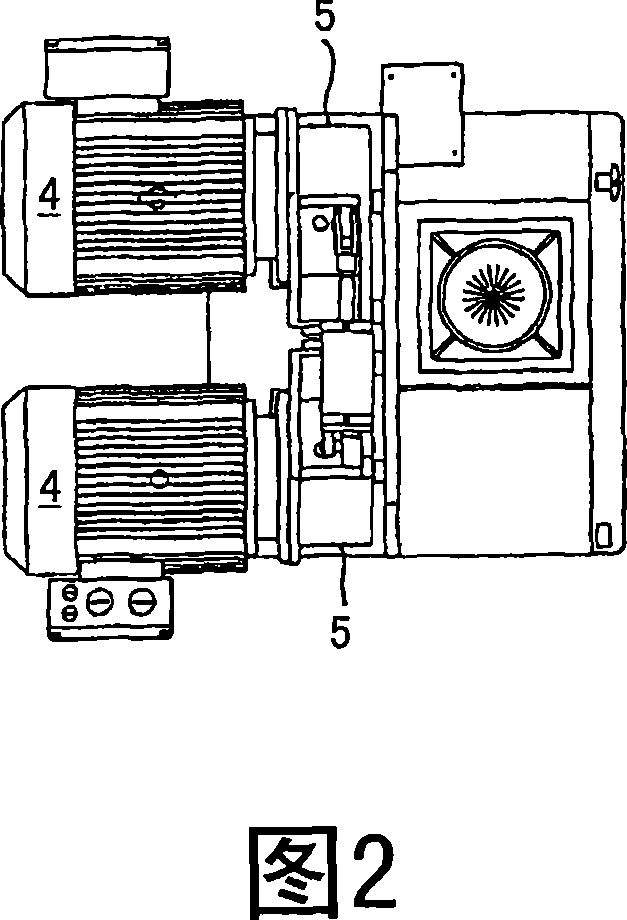

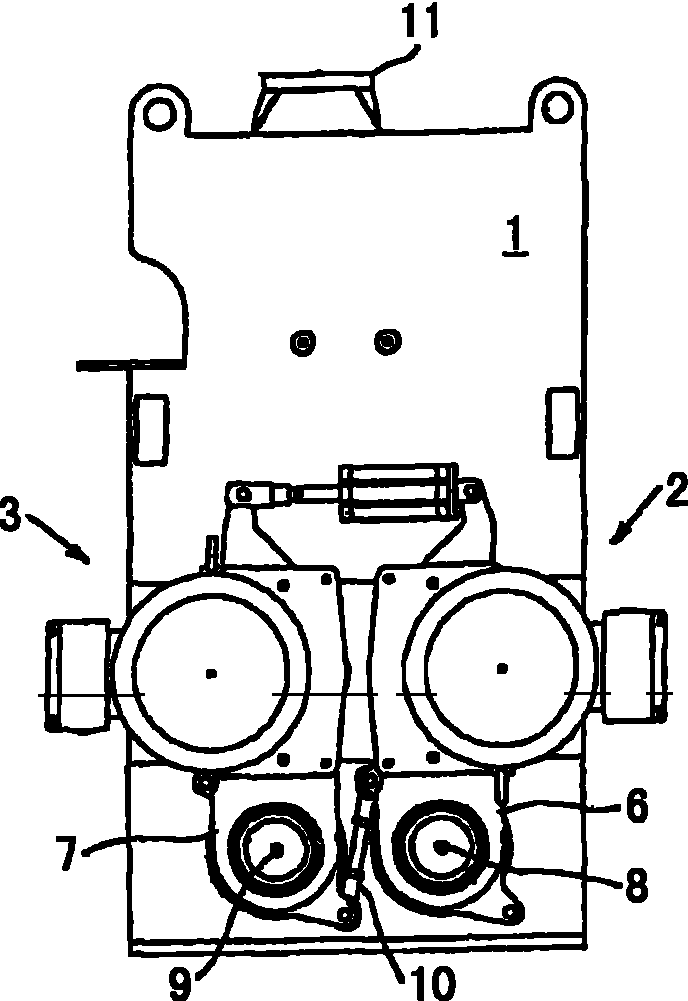

[0016] The rubber roll sheller according to the invention has a frame 1 (not clearly shown) with a feeder 11, a pair of movable rubber rolls 2, 3 (not clearly visible), and a product output. The rubber rollers 2,3 are respectively equipped with drives, and the compact transmission is in the additional pendulums 6,7. The compact transmission is provided with symmetrical ends top and bottom, so that the transmissions can be left and right mirror images of each other, and the additional rockers 6, 7 and the upper rocker rods can be connected. Additional rockers 6 , 7 are pivotally connected to support shafts 8 , 9 of frame 1 and are interconnected by coupling rods 10 . The additional rocker is mounted on the support shafts 8, 9 via tapered roller bearings of the pivot bolts in such a way that play and friction are minimized.

[0017] Since the rollers 2, 3 are movably mounted, the contact pressure of the rubber rollers 2, 3 can be controlled by the actuator.

[0018] Each motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com