Wring-out device for cleaning element for wetting and moisting cleaning tool

A technology of cleaning components and wet method, which is applied in the direction of cleaning equipment, cleaning machinery, carpet cleaning, etc., and can solve the problems of increasing the difficulty of operating the wringer device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

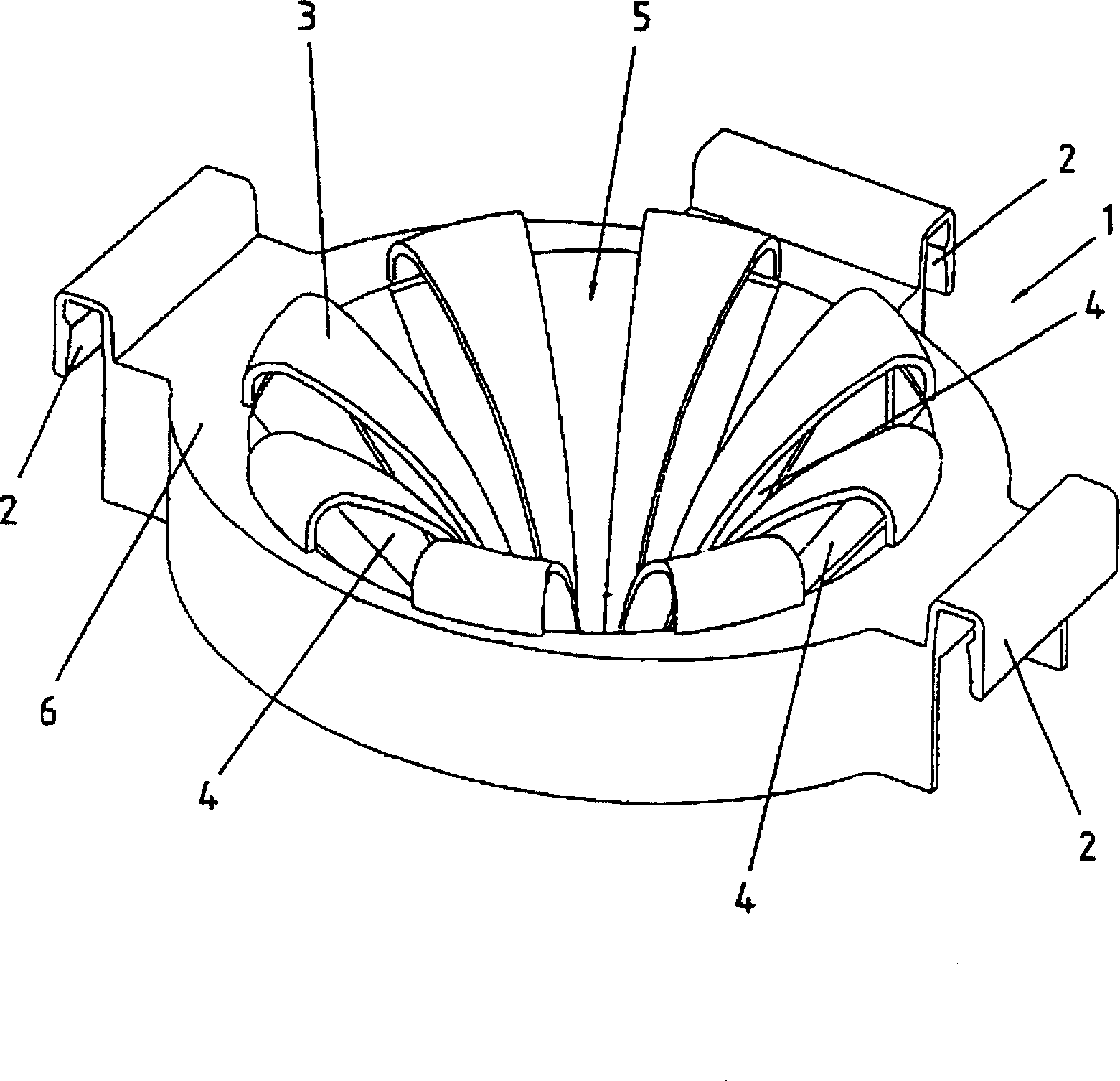

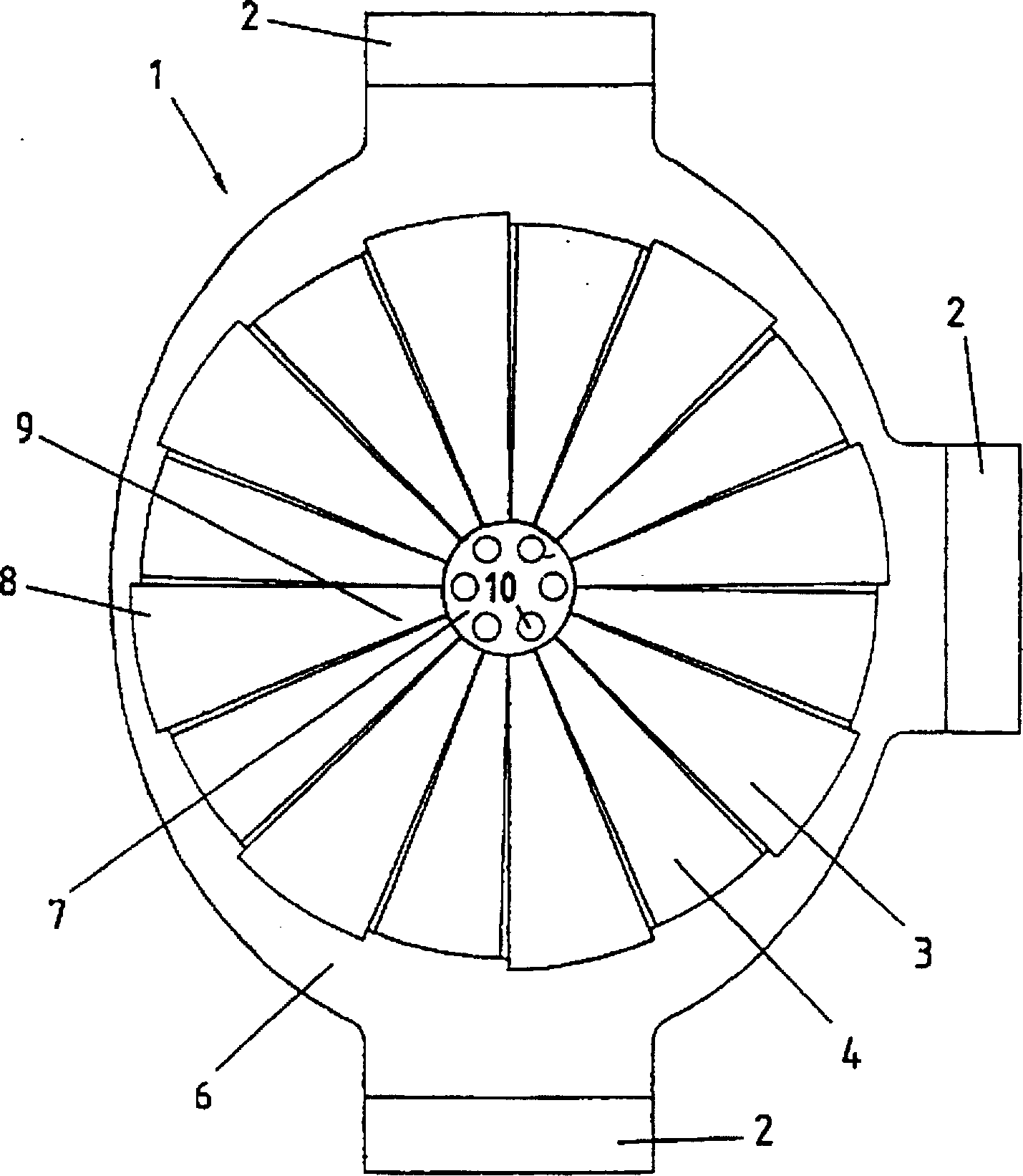

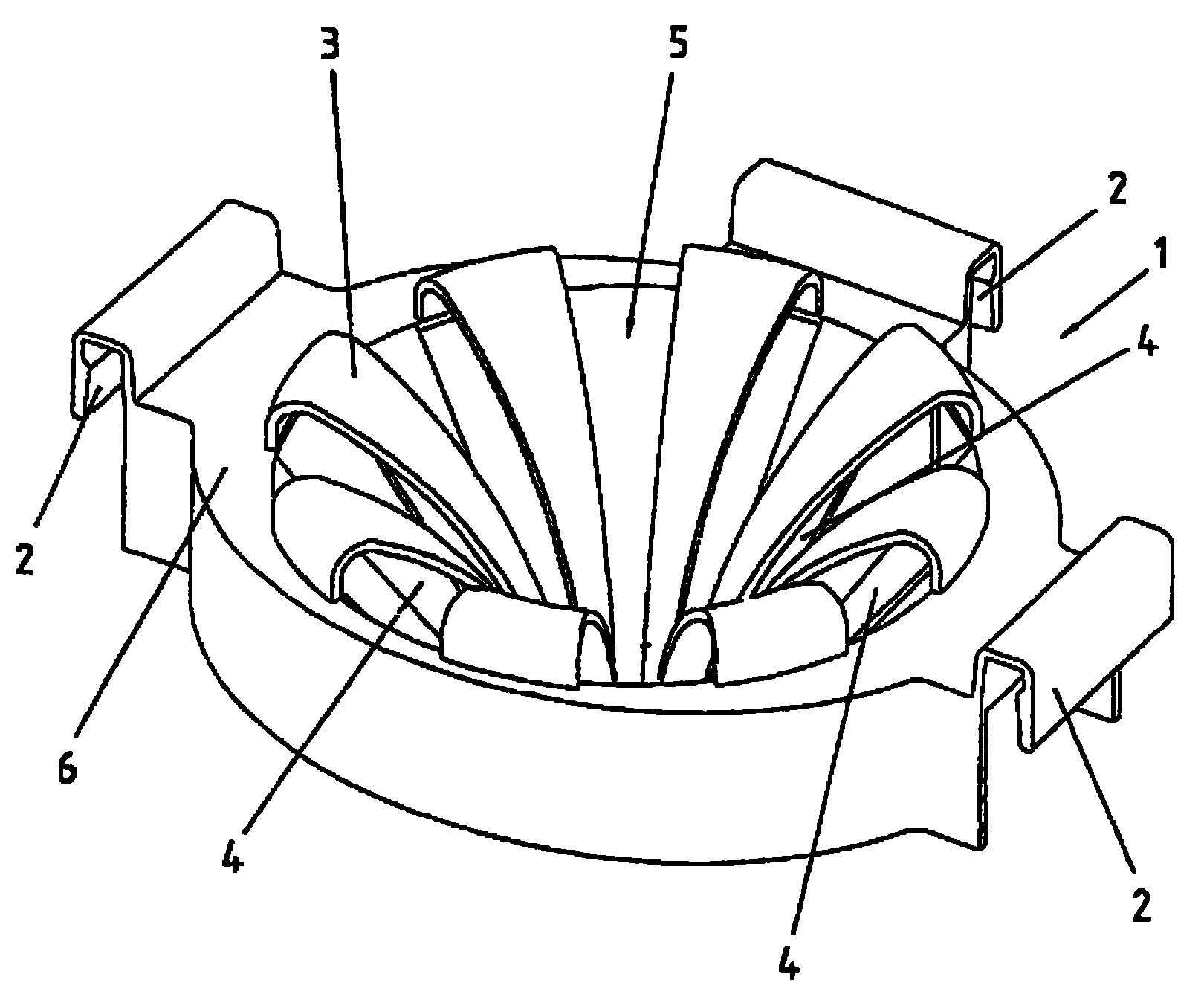

[0019] figure 1 A perspective view of an embodiment of the wringing device of the present invention is shown in FIG. The wringer device is formed by means of a receptacle 1 , the access opening above which a cleaning element such as a scrubbing mop can be inserted and wrung out in a squeeze cage 5 .

[0020] The wringing is effected by a downwardly directed pressing force of the mop and possibly also by turning and twisting of the mop.

[0021] The extrusion cage 5 is formed by elastically formable wall parts 3 which are formed in the form of tongues and which taper downwards from a support frame 6 of the receptacle 1 to form a cage. Each spring element 3 has a convex curvature and forms in the cage an inner diameter which increases when the cleaning element is pressed in, in other words the curvature of the spring element decreases. Each spring element 3 has an upper end 8 which is preferably arch-shaped and is formed on the carrier frame 6 . If one imagines a tangent at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com