Ozone-water air washing-dirnfecting apparatus for cleaning air

A technology for sterilizers and air compressors, which is used in disinfection, air quality improvement, air conditioning systems, etc., can solve problems such as difficult cleaning, short discharge wire life, filter failure, etc., and achieve sufficient washing, improved dissolution, and high surface activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

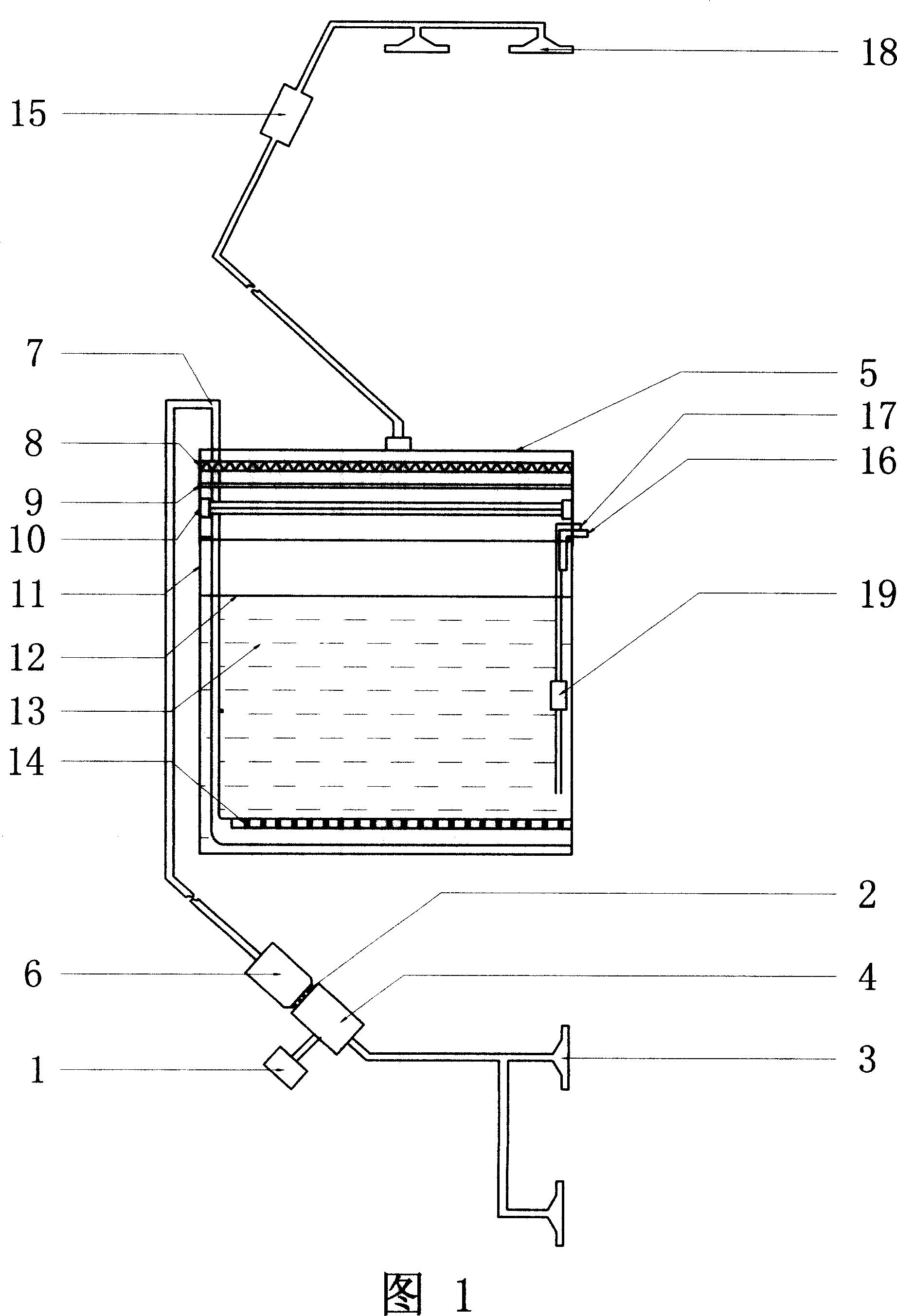

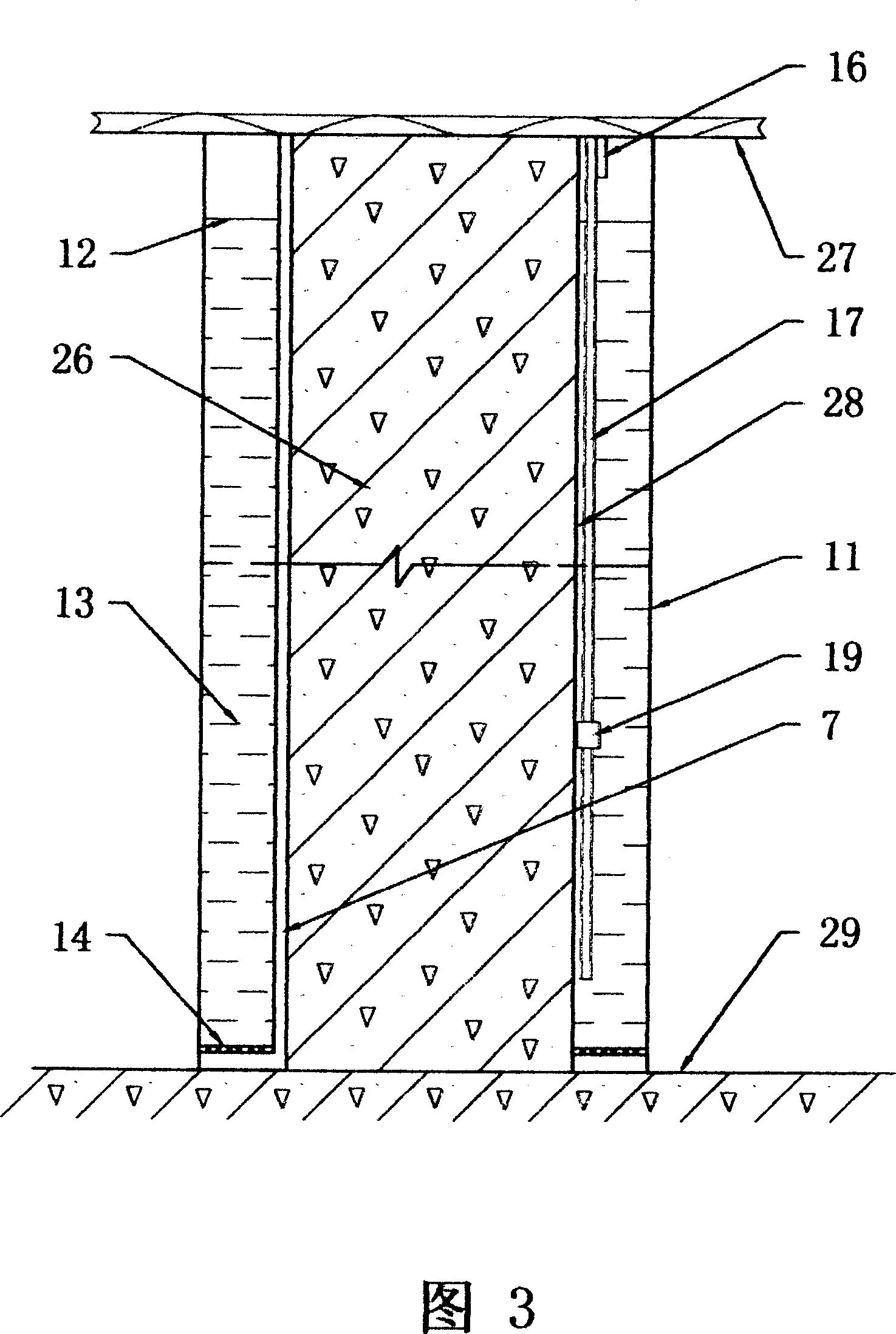

[0030] In Fig. 1, the air inlet of the air compressor 6 is connected to one end of the gas mixing box 4, and the exhaust port and the air return port 3 of the ozone machine 1 are connected to the other end of the gas mixing box 4, and the air compressor 6 will Ozone and air are inhaled into the gas mixing box 4 together, and the mixed gas is pressed into the gas injection pipe row 14 through the primary filter 2 and the air compressor exhaust pipe 7; the atomized mixed gas enters the bottom of the water 13 in the form of a fine mist jet, and carries out Impact cleaning and floating above the water level line 12; the upper part of the washing bucket 11 is equipped with a clean air cover 5, and the clean air cover 5 is sequentially equipped with an air humidity adjustment grid 9, a residual ozone remover 8, and a clean air cover 5. The upper part is connected with fan 15, and the cleaned clean air is exhausted indoors through air humidity regulating grid 9, residual ozone remover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com