Process for weaving three-dimensional fabrics with special-shaped cross-section and special-purpose heald wire

A technology of three-dimensional fabrics and special-shaped cross-sections, applied in fabrics, textiles, papermaking, textiles, etc., can solve the problems of weaving three-dimensional fabrics with few layers, single structure, and inability to weave thick fabrics, etc. The effect of high shape precision and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The so-called special-shaped section of the woven three-dimensional fabric with special-shaped cross-section in the present invention refers to the overall structural state of the cross-section of the fabric along the warp direction or weft direction. The present invention can be used for weaving the fabrics of various special-shaped cross-sections as listed in Table 1 (but not limited to Table 1). Weft can be woven into shape.

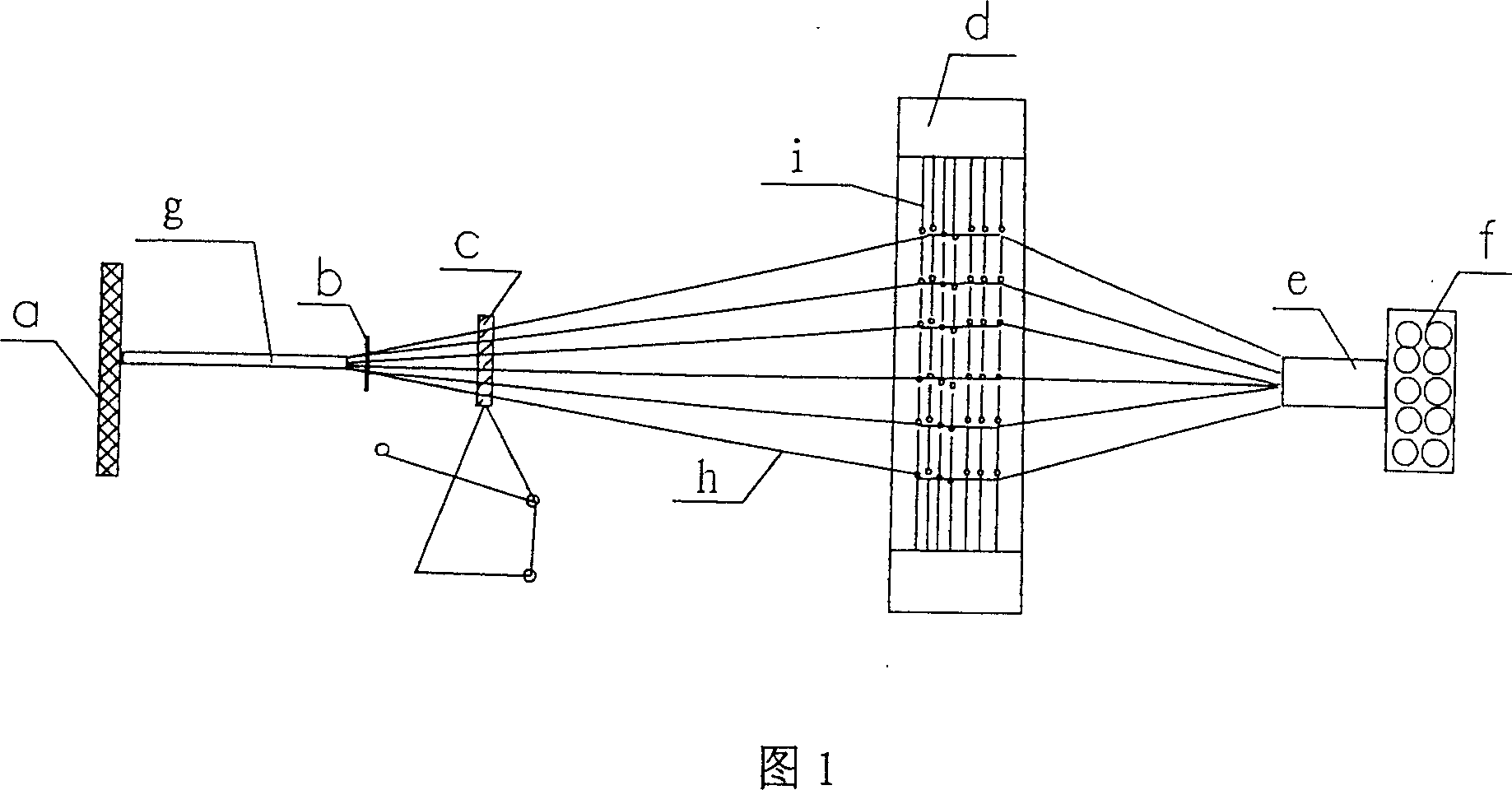

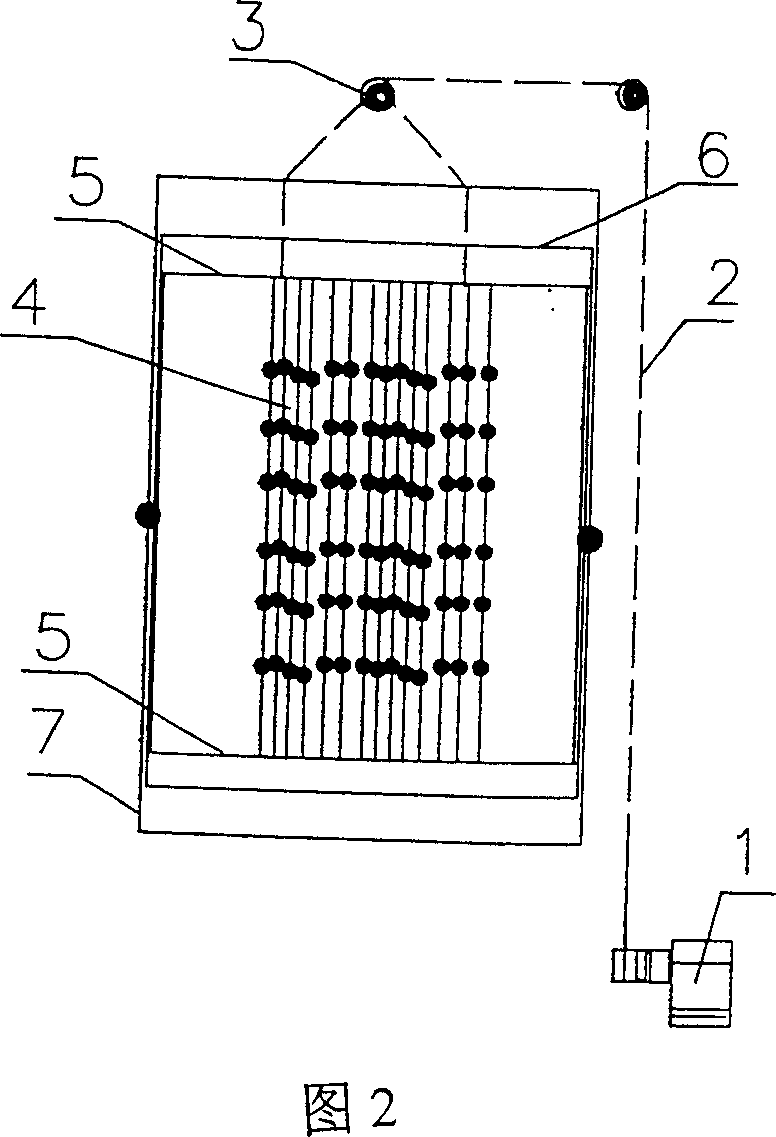

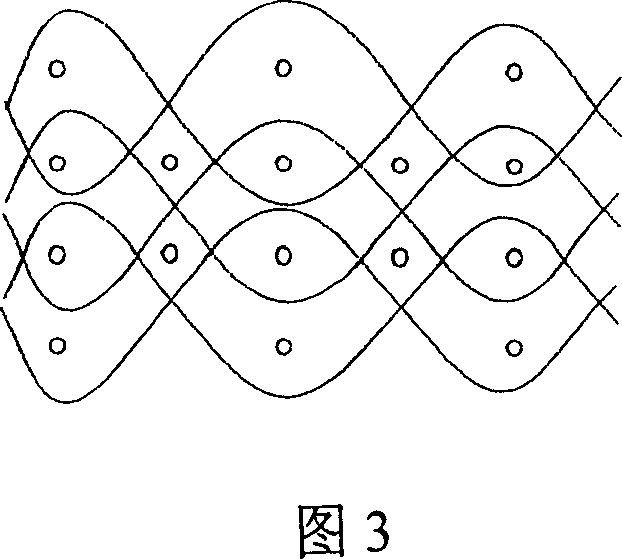

[0037] The weave structure of the three-dimensional fabric is determined by the relative displacement lifting program of the heald frame, and different lifting programs make the fabric have different structures. If there are n layers of warp yarns, the heald frames are aligned to form n-1 layers of openings of equal height; the front and rear heald frames move relative to each other to form n+1 layers of openings of equal height. There are two types of lifting of the heald frame: straight cross shallow joint structure (as shown in Figure 3); c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com