Glass steel reinforced composite wooden floor and its preparing process

A production method, the technology of glass fiber reinforced plastics, is applied in the field of production of reinforced composite wood flooring, which can solve the problems of air pollution, harm to human health, lack of elasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

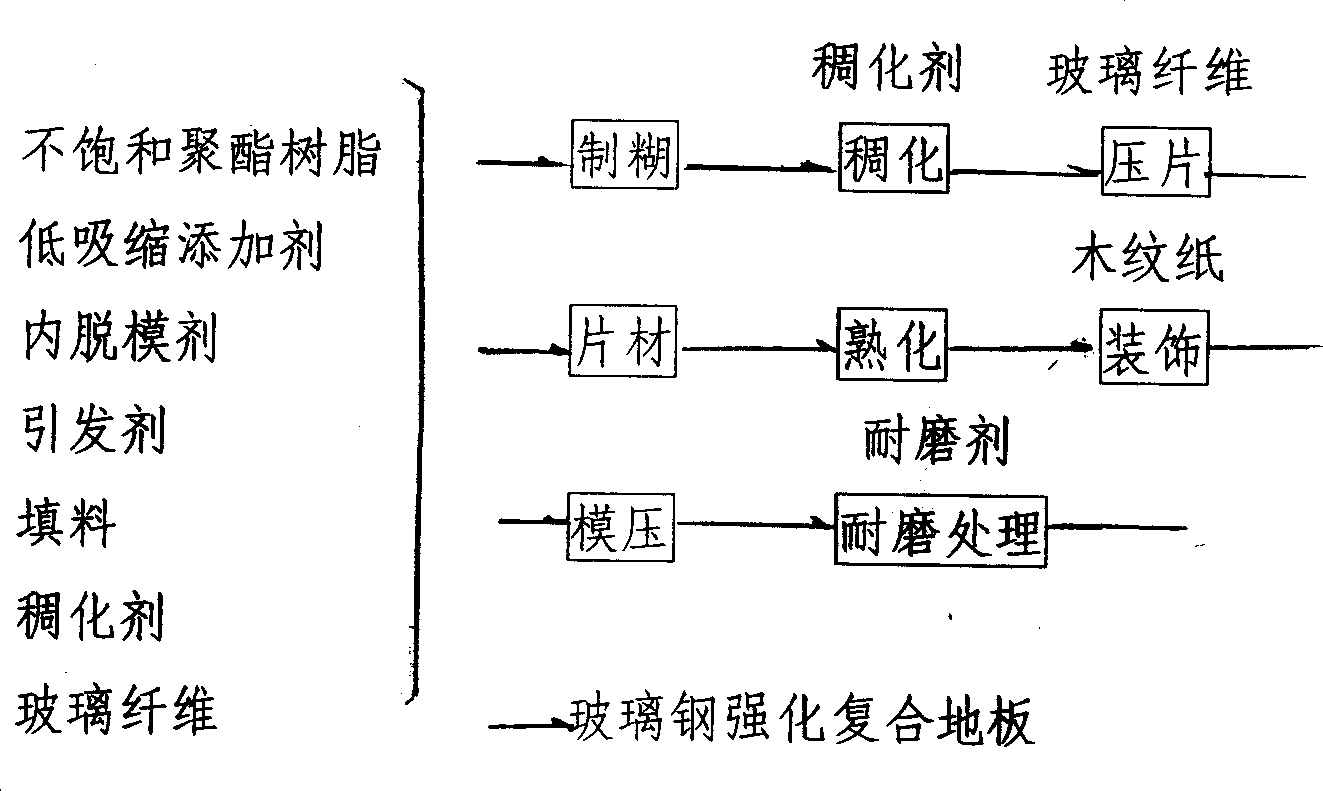

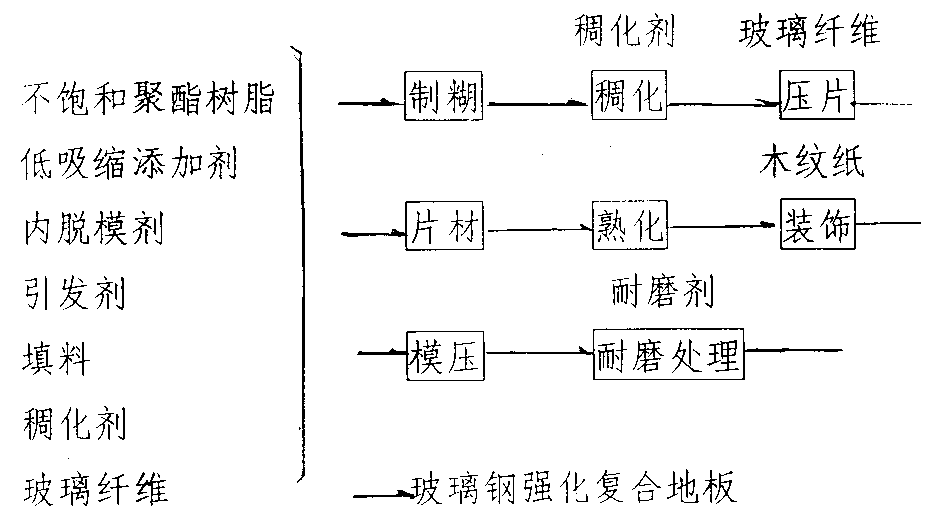

Method used

Image

Examples

Embodiment Construction

[0017] First put the unsaturated polyester resin into the reaction kettle, start stirring, and then put in the low-shrinkage additive; tert-butyl peroxybenzoate; zinc stearate, and heavy calcium carbonate and stir evenly for 2 hours. Then put the paste into the thickening barrel by 100kg each time, move the thickening barrel under the high-speed mixer, add light magnesium oxide and stir at a high speed for 5 minutes. Pour the thickened paste into the hopper of the sheet machine; the glass fiber is introduced into the distributor, and the sheet machine is started to press the sheet. Move the pressed sheet to a curing room for curing at 30°C for 48 hours. The cured sheet is cut into pieces according to the specifications, and the wood grain paper is laid on the upper surface of the two overlapping sheets, put into the mold and pressurized at 16Mpa, the temperature is 155°C, and the pressure is held for 3 minutes to release the mold. Spray Al on the upper surface after the mold ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap