High-efficient engine

An engine and high-efficiency technology, applied in variable displacement engines, machine/engines, reciprocating piston engines, etc., can solve problems such as unreasonable engine transmission structures, reduce fuel consumption, reduce construction costs, and reduce engine weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

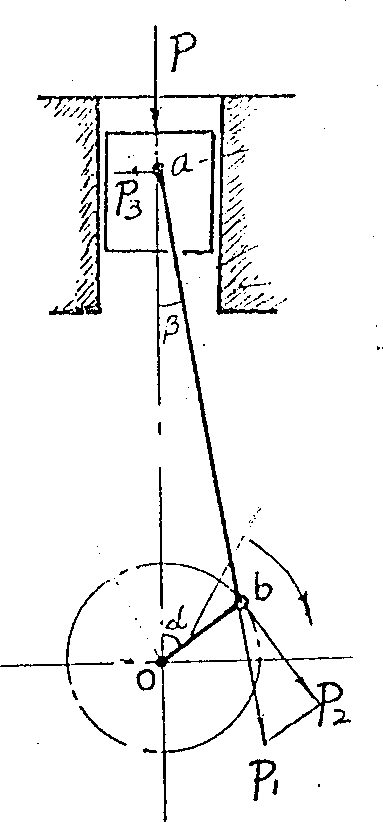

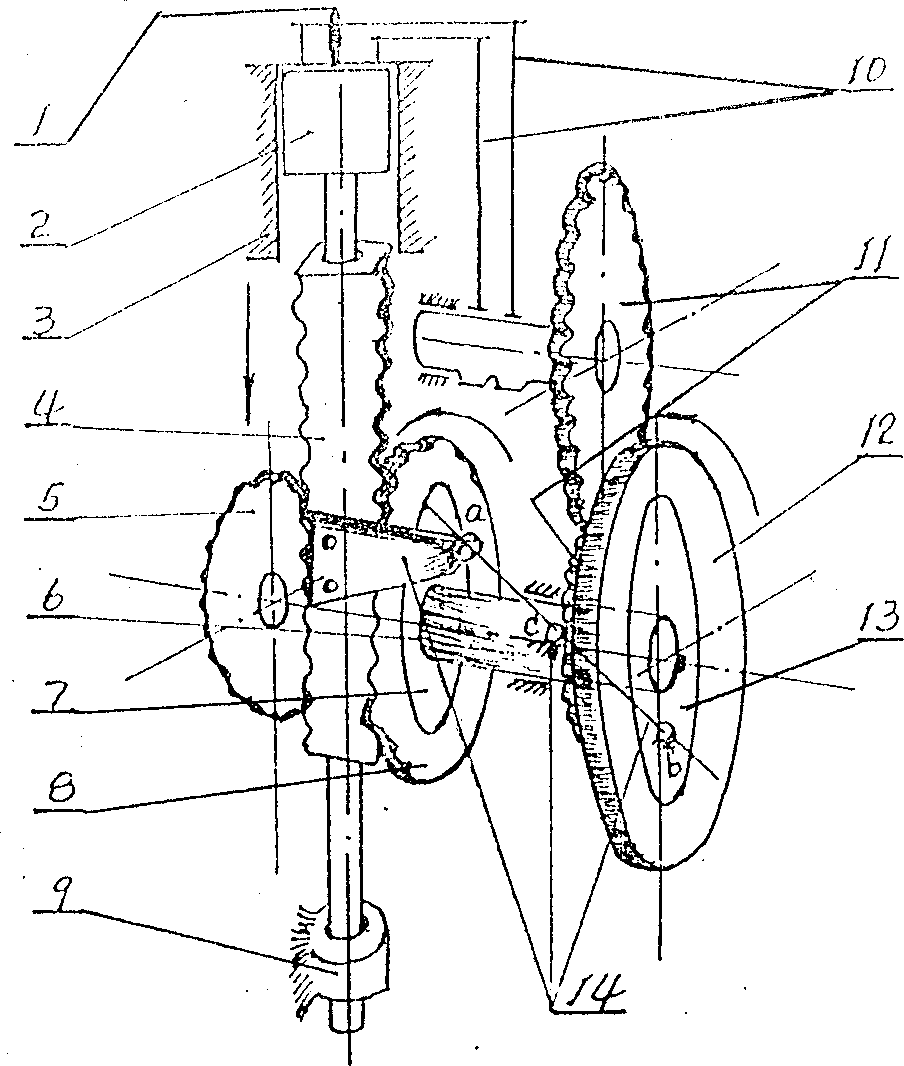

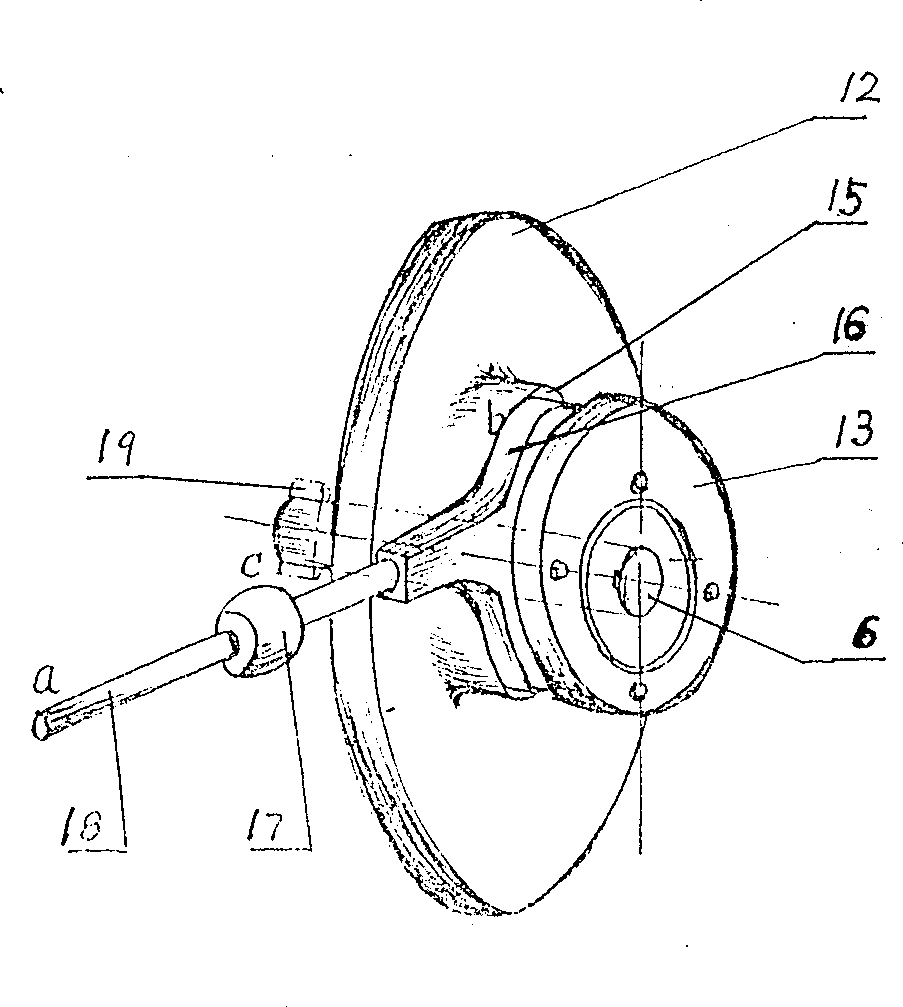

[0017] The structures disclosed in the above drawings are embodiments of the present invention. In the figure, 1 is the fuel injector; 2 is the piston; 3 is the cylinder block; 4 is the piston rod with rack; 5 is the transmission gear; 6 is the main shaft; Main shaft gear; 9 is the bearing located at the bottom of the piston rod; 10 is the intake and exhaust mechanism; 11 is the timing gear; 12 is the flywheel; 13 is the overrunning clutch; 14 is the lever transmission mechanism (including lever ab and its hinges a, b, c and the connecting block located on the rack); 15 is a circular eccentric groove located at the middle part of the flywheel 12; 16 is a circular eccentric ring located in the eccentric groove; 17 is a supporting hinge (ie C); 18 is a lever (i.e. ab); 19 is the braking device that prevents the main shaft from idling; 20 is the outer ring of the clutch; 21 is the inner ring of the clutch. The specific situation of the above-mentioned overrunning clutch can be f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com