Cocurrent control method for goods

A control method and article technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of reduced merging efficiency, reduced merging efficiency, and reduced work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

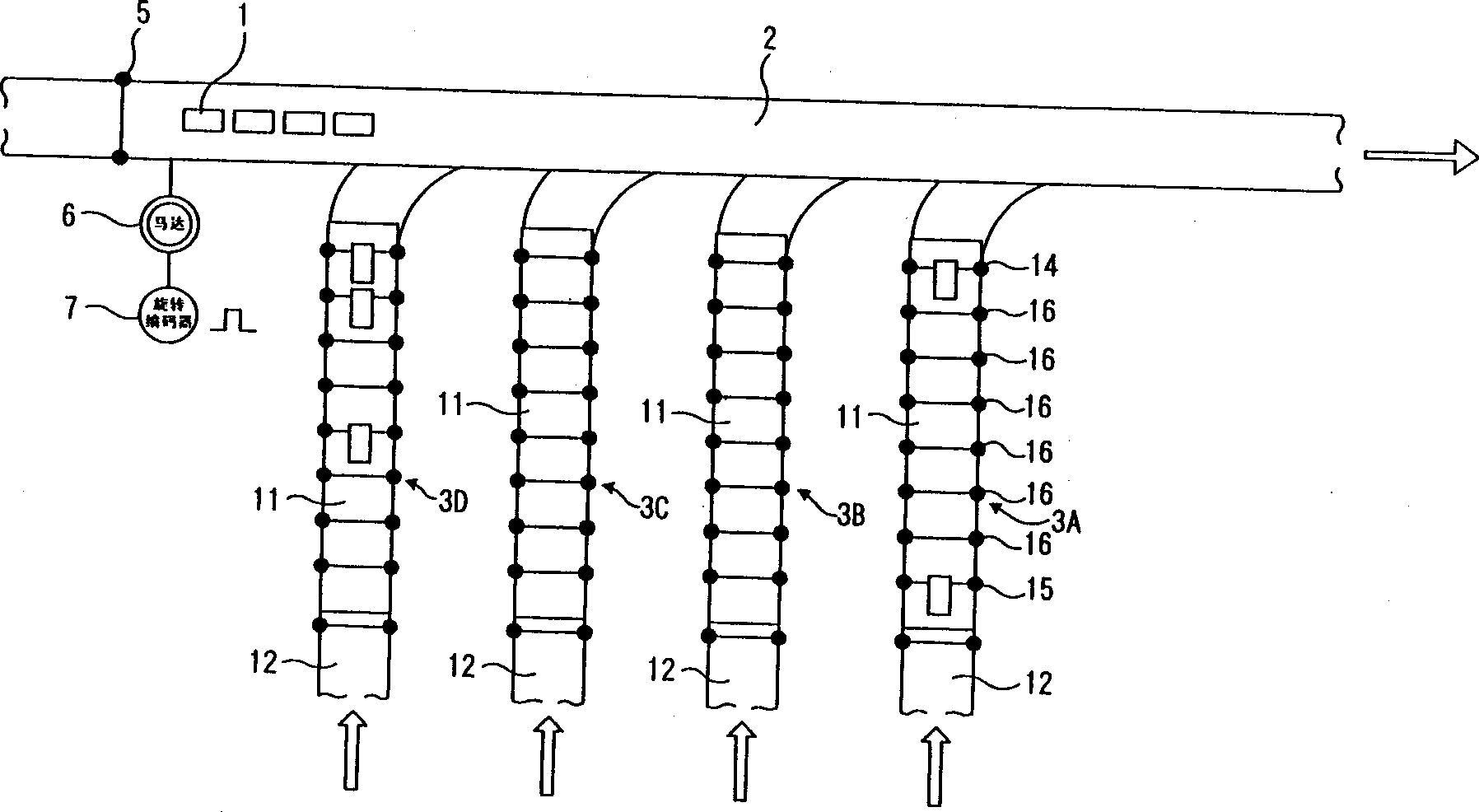

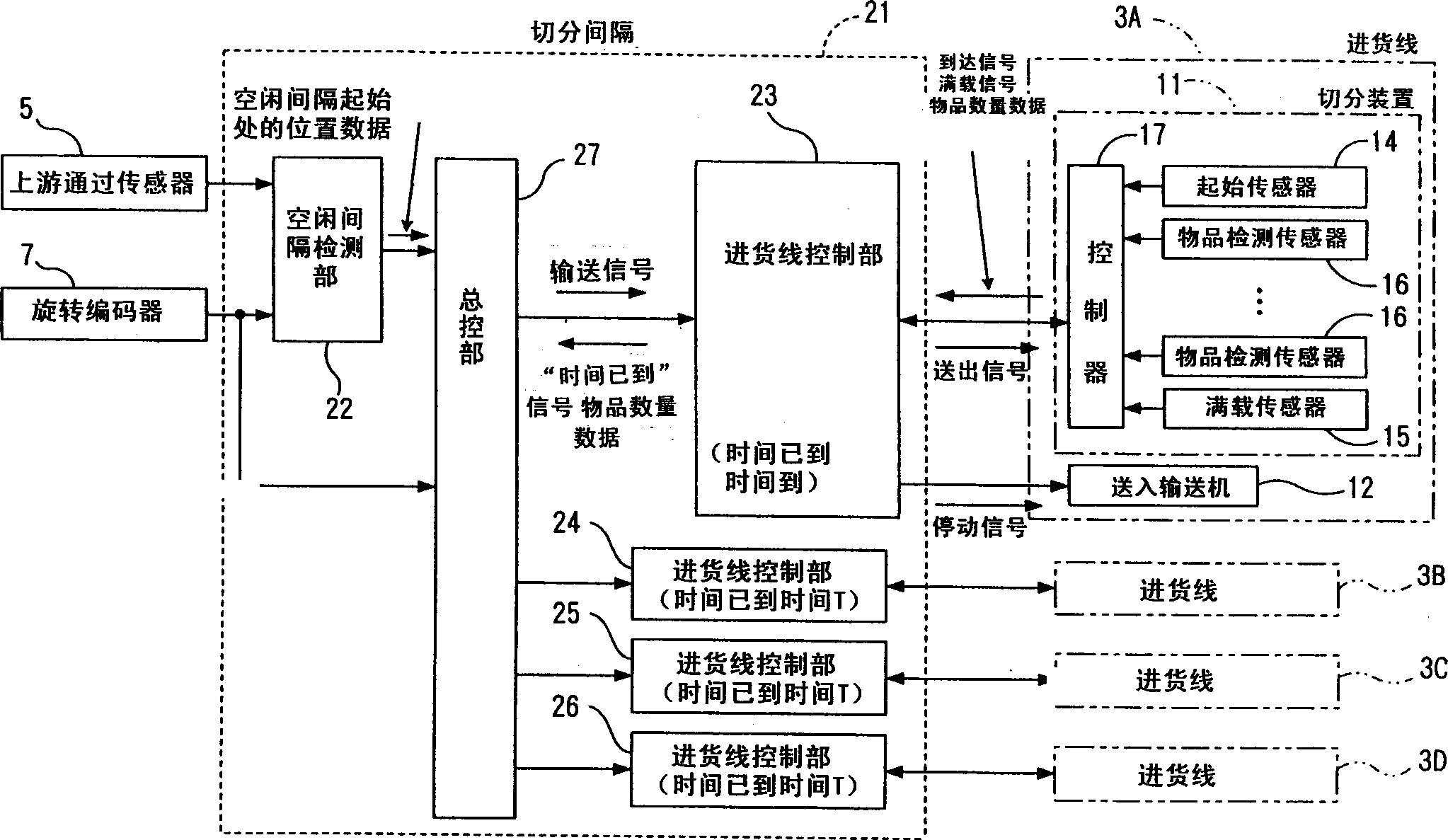

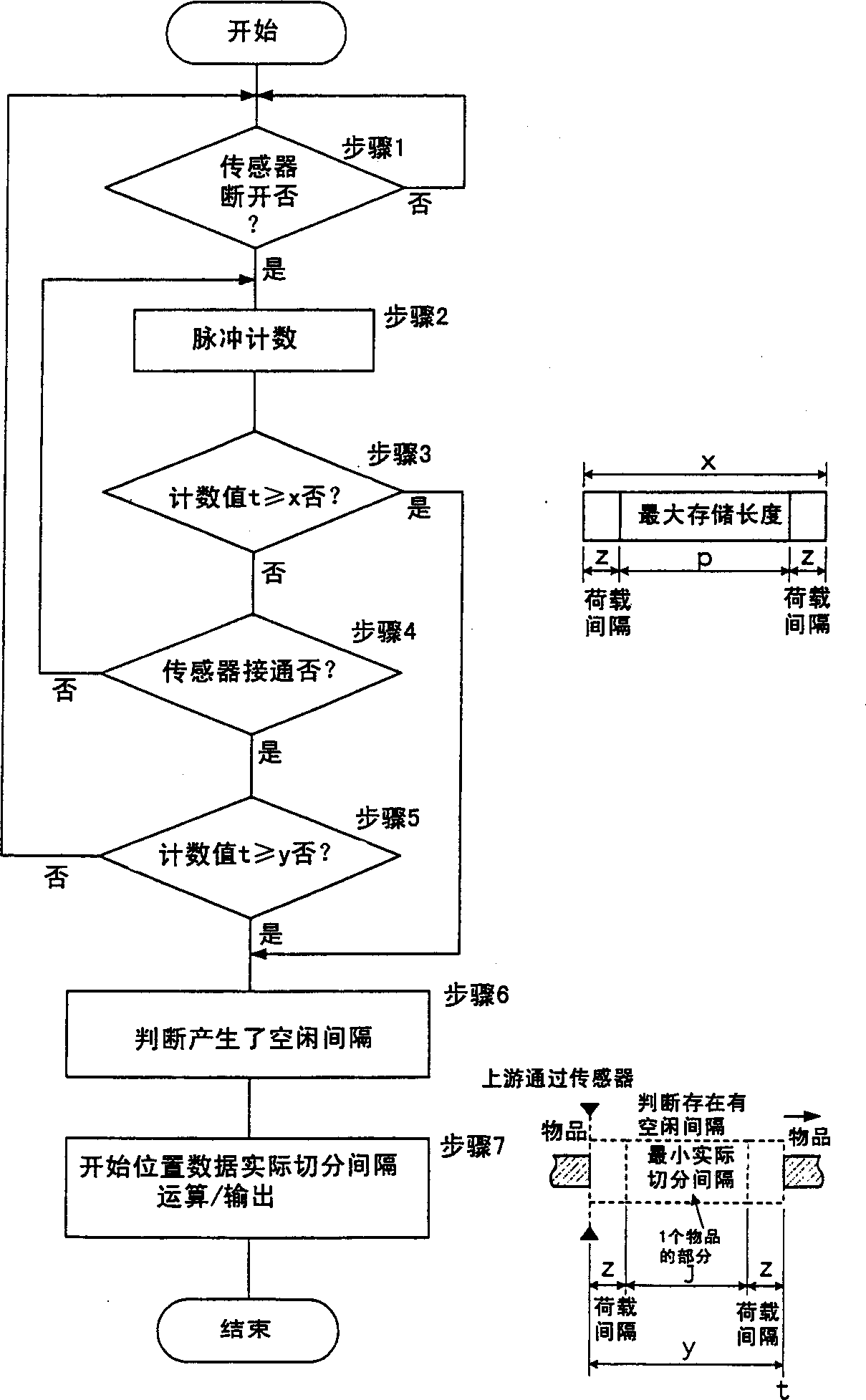

[0016] Reference below Figure 1~5 The article merging control method according to an embodiment of the present invention will be described.

[0017] The conveying equipment adopting the article merging control method of the present invention includes a trunk line (an example of a main conveying path) 2 for conveying articles 1 and an inbound line (sub-conveyor) that merges articles 1 onto this trunk line 2 in multiple rows (4 rows in the figure) Road example) 3 (3A, 3B, 3C, 3D).

[0018] Trunk 2 consists of a roller transport mechanism. In the trunk line 2, an upstream passing sensor 5 is provided upstream of the confluence point of the four rows of inbound lines 3. The upstream pass sensor 5 is used to detect the length in the conveying direction when the article 1 is conveyed by the trunk line 2, and is composed of a photoelectric sensor. A rotary encoder 7 is connected to the drive motor 6 of this roller conveyor.

[0019] The articles 1 conveyed through the trunk line 2 are us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com