Moulding die, mould system, recording medium base plate, recording medium, optical disc base plate, optical disc, moulding die making method

A technology for recording media and substrates, which is applied in the manufacture of optical record carriers, optical record carriers, thin material processing, etc., and can solve problems such as high manufacturing costs, obstruction of mold expansion and contraction, and increased dynamic imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

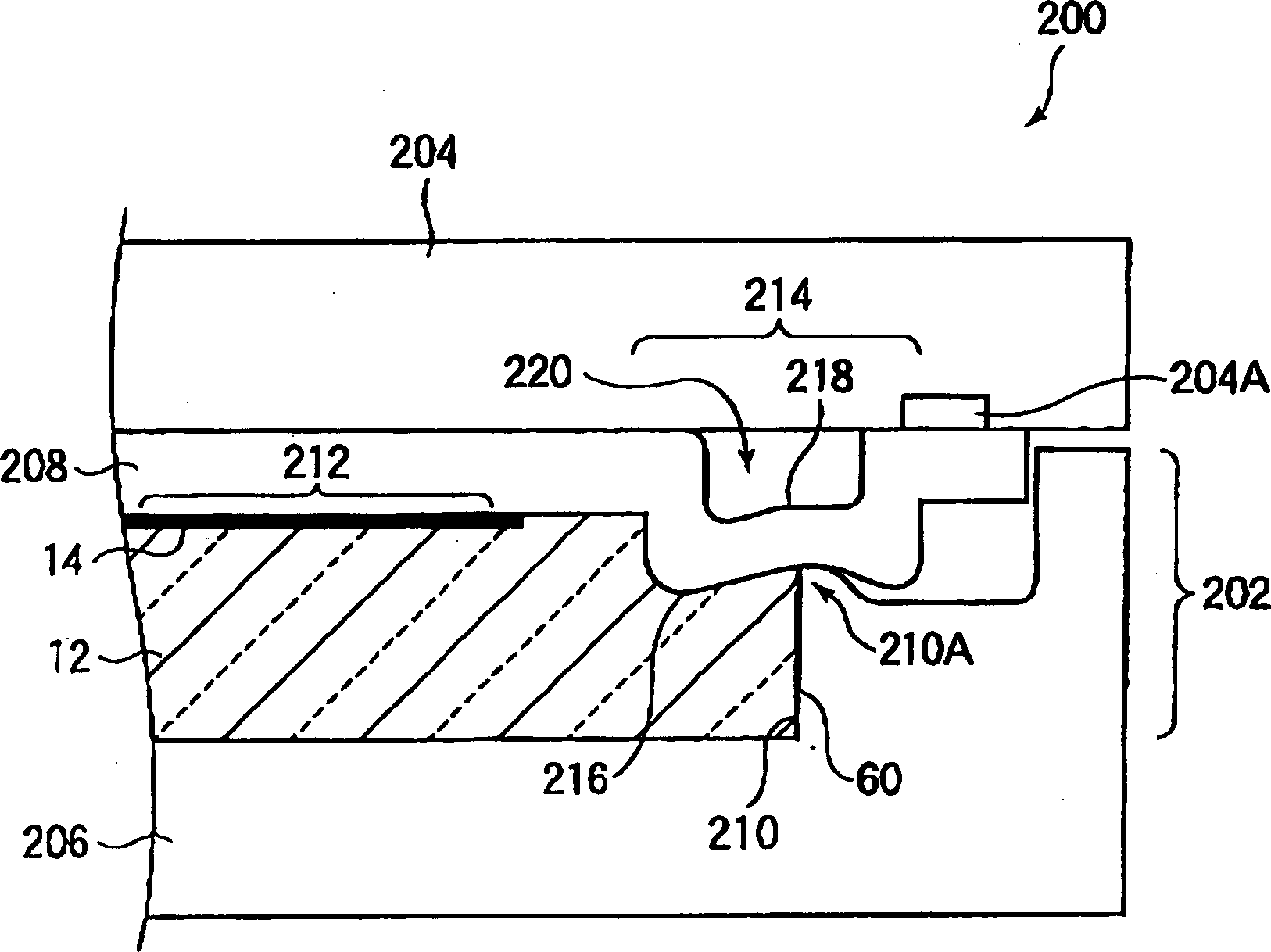

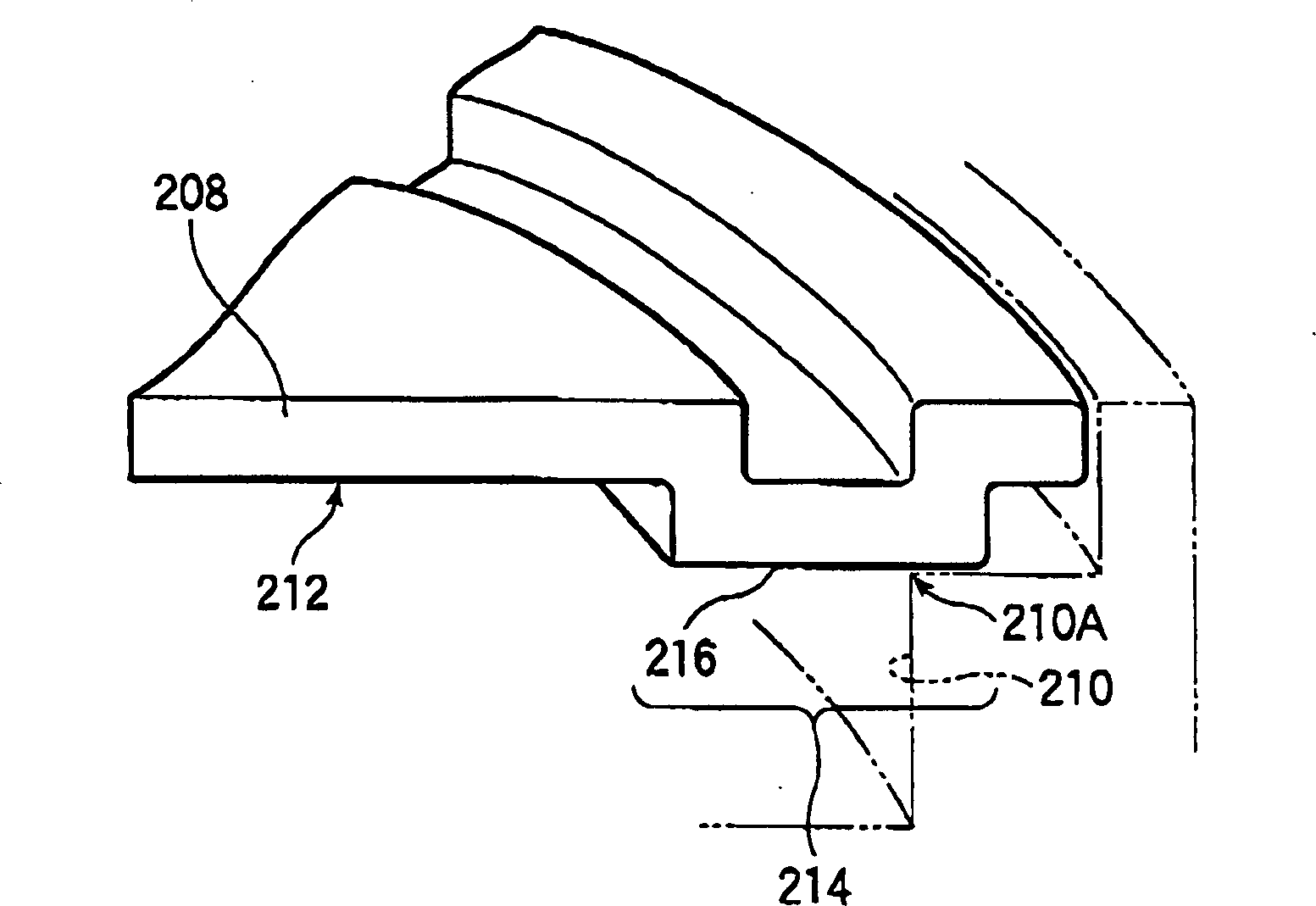

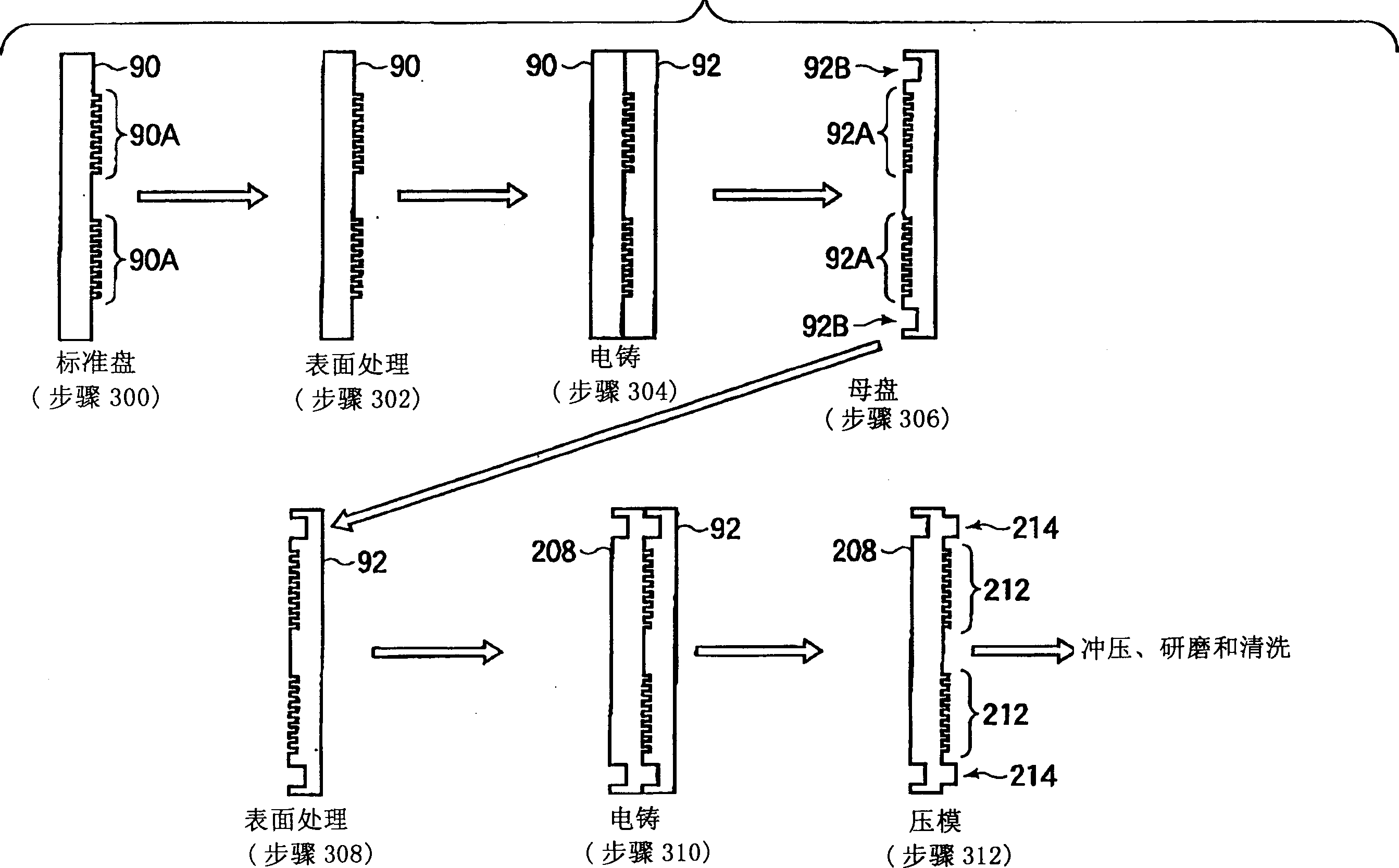

[0074] figure 1 The mold system 200 of this embodiment is shown in . The mold system 200 includes an annular mold 202 , planar molds 204 , 206 arranged face to face, and a die 208 disposed on one side ( 204 ) of the planar dies 204 , 206 . Here, the flat die 206 is provided integrally with the annular die 202 . The ring mold 202 includes an inner peripheral wall 210 that can form the outer peripheral surface 60 of the substrate 12 for the recording medium. In addition, the front surface and the back surface of the substrate 12 are formed by the above-mentioned pair of planar molds 204,206. The stamper 208 has a reprint surface 212 on which minute unevenness for reprinting predetermined information is formed, so that the information recording surface (area) 14 is formed on the substrate 12 . In addition, the above-mentioned information recording s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com