Piezoelectric driving vibratory feeder and piezoelectric element driving feeder

A vibrating feeding and piezoelectric driving technology, which is applied in the direction of electrical components, vibrating conveyors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of higher overall height of the device, longer spring length, and surrounding Problems such as machine configuration relationship obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

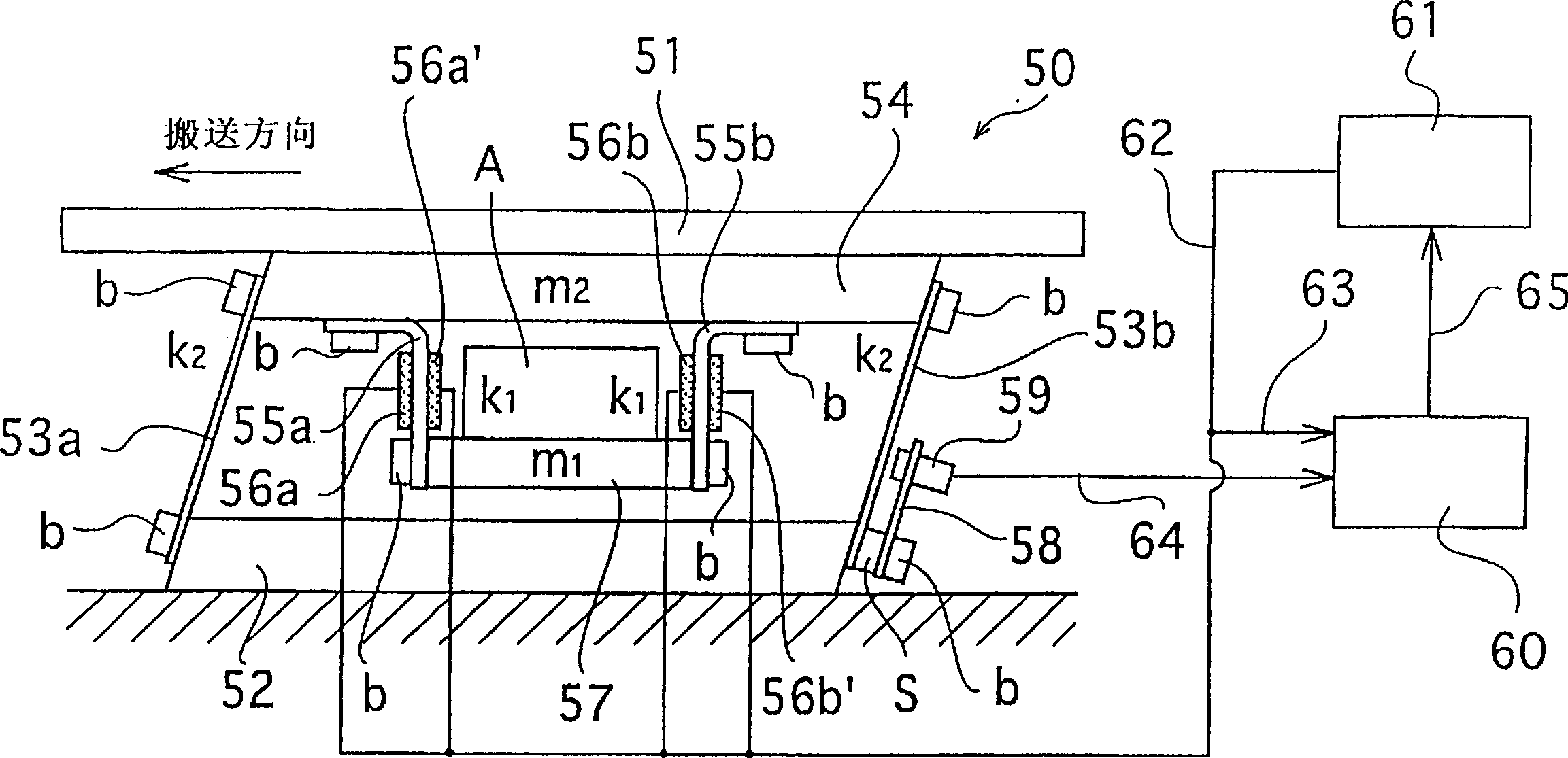

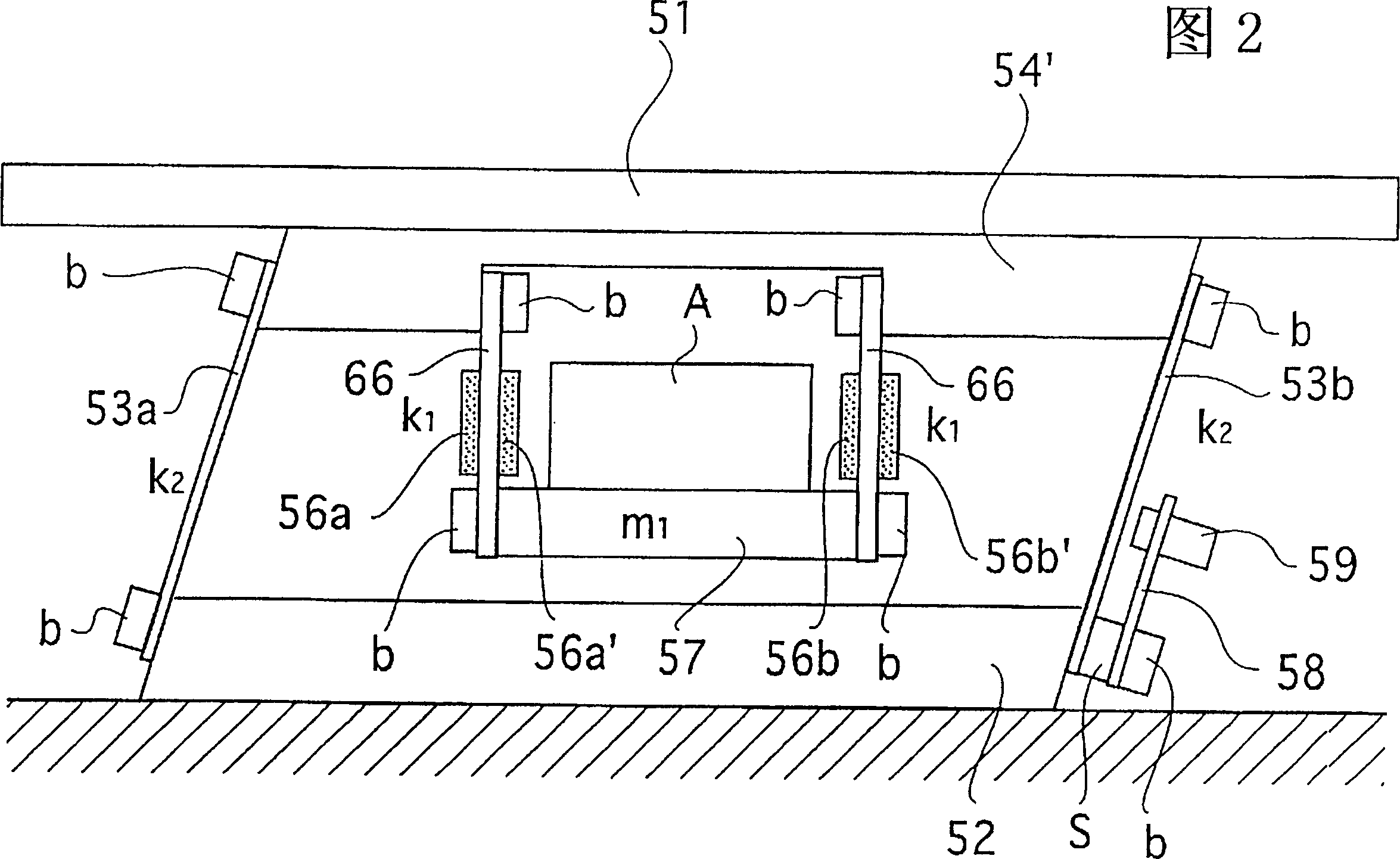

[0041] Below, refer to figure 1 A first embodiment of the present invention will be described.

[0042] exist figure 1 In the piezoelectric-driven vibrating feeder 50 of the present invention, the conveying trough 51 is combined with the base 52 through a pair of front and rear spring pieces 53a, 53b arranged obliquely. Moreover, the upper ends of the spring sheets 53a, 53b are fixed on the spring sheet mounting block 54 integrated with the delivery trough 51, whereby the delivery trough 51 is supported on the spring sheets 53a, 53b so that it can be substantially perpendicular to the spring sheet Vibrate in the direction of the longitudinal direction of 53a, 53b.

[0043] By bolt b, a pair of spring sheets 55a, 55b close to the reverse L shape are fixed below the spring sheet mounting block 54, and the piezoelectric elements 56a, 56a' and 56b, 56b' are pasted on the spring sheets 55a, 55b. two sides. Furthermore, according to the present invention, the common opposing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com