Siding for rolling stock

A technology for wall panels and vehicles, applied to railway car bodies, transportation and packaging, railway car body parts, etc., can solve problems such as troublesome maintenance operations, lack of preventive measures, and difficult loading and unloading of supporting shaft structures, and achieve the effect of ensuring traffic safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiment of the invention

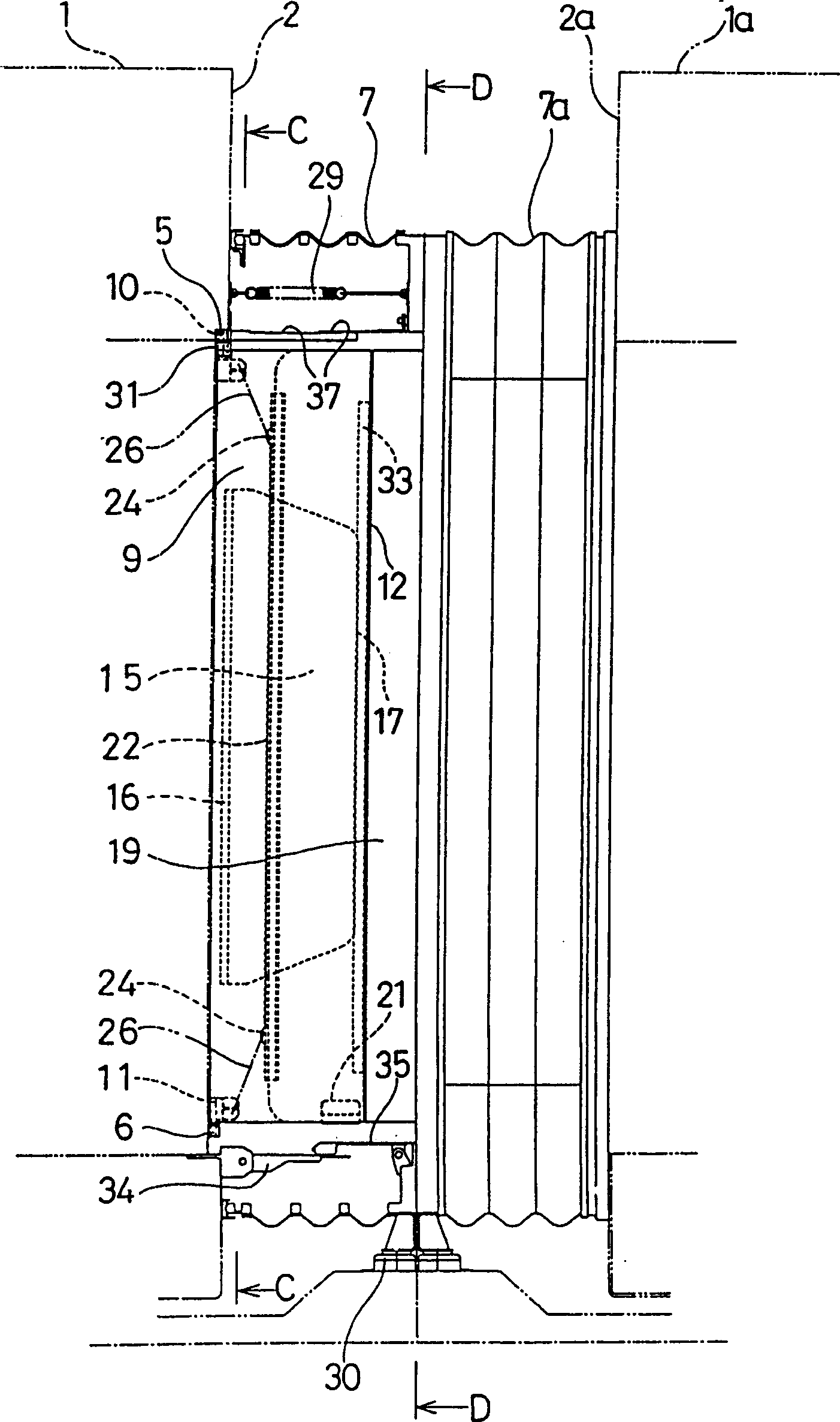

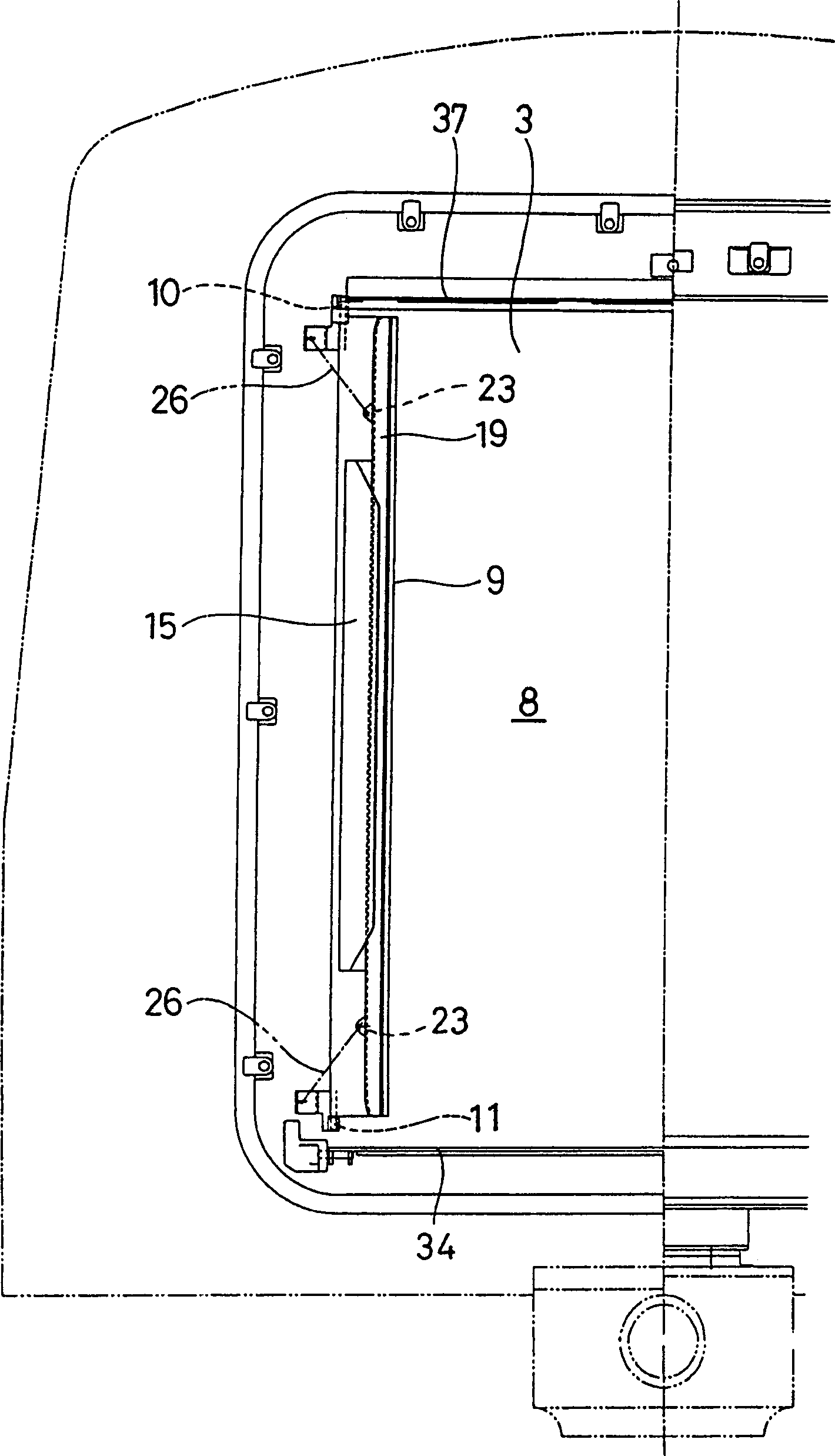

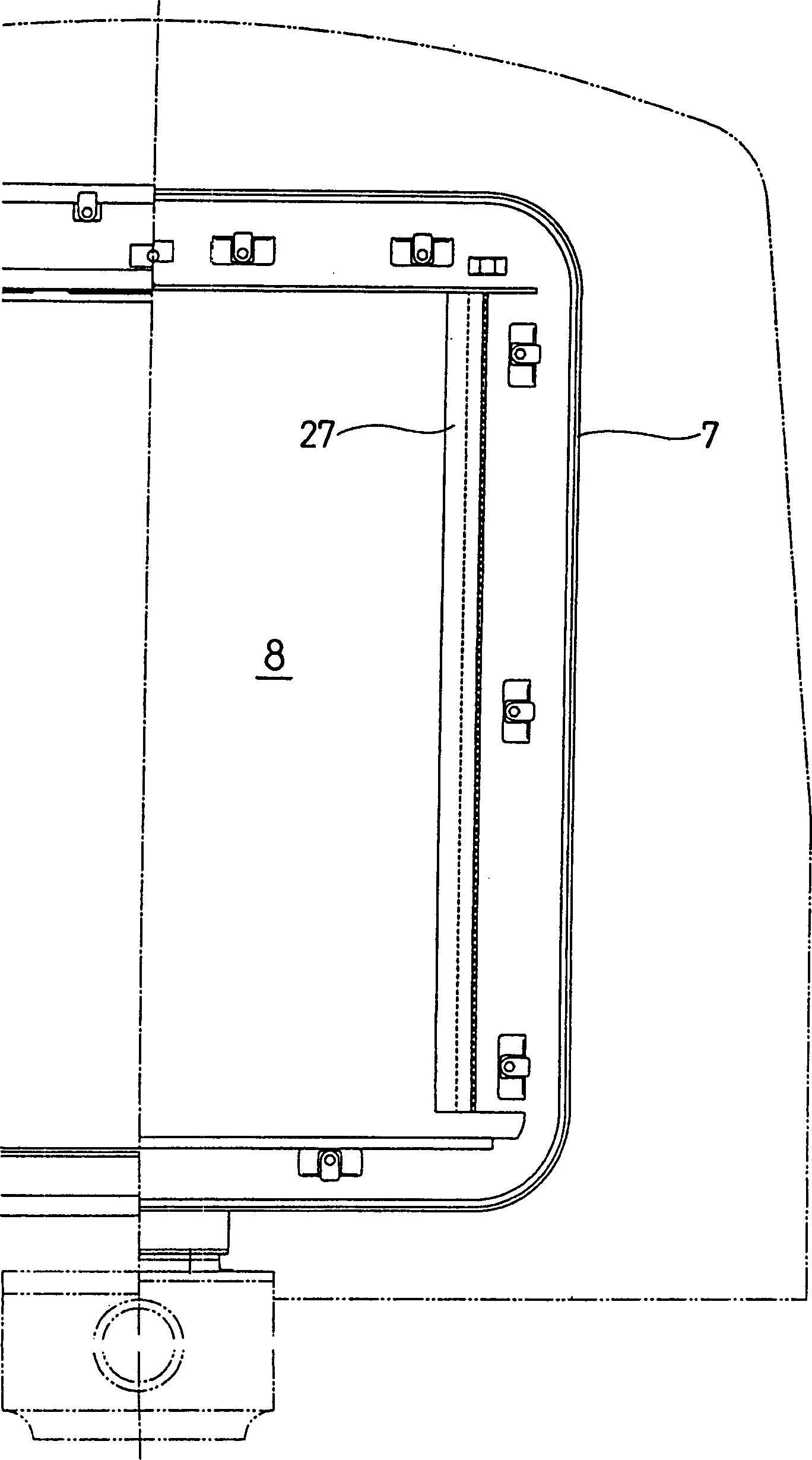

[0037] in accordance with Figure 1 to Figure 14 The examples illustrate embodiments of the invention.

[0038] exist Figure 1 to Figure 13 In the first embodiment of the present invention, the side column portion 4 of the inlet and outlet 3 on the end face 2 of the connected side of the car body 1 (see Figure 4 , Figure 5 ) are fixedly provided with hinge seats 5, 6 with vertical shaft holes at the upper and lower positions of the side columns. On the side portion parallel to the passage direction A-B of the passage 8 surrounded by the shed 7, that is, on one side of the carriage body 1, a side rotating wall plate 9 constituting the side wall is erected. The hinge shafts 10, 11 protruding from the vertical direction of the upper and lower ends of the part are rotatably fitted in the aforementioned hinge seats 5, 6, and the rotating wall plate 9 can rotate horizontally around the hinge shafts 10, 11. The rotating wall plate 9 is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com