Record regenerator

A technology for recording and reproducing devices and recording media, which is applied in the directions of data recording, recording information storage, optical recording/reproducing, etc., and can solve the problem of high minimum height of the guide shaft, inability to cope with the thinning of the recording and reproducing device, and the setting of adjustment mechanisms Larger space and other issues, to achieve the effect of reducing the number of parts and improving the efficiency of assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

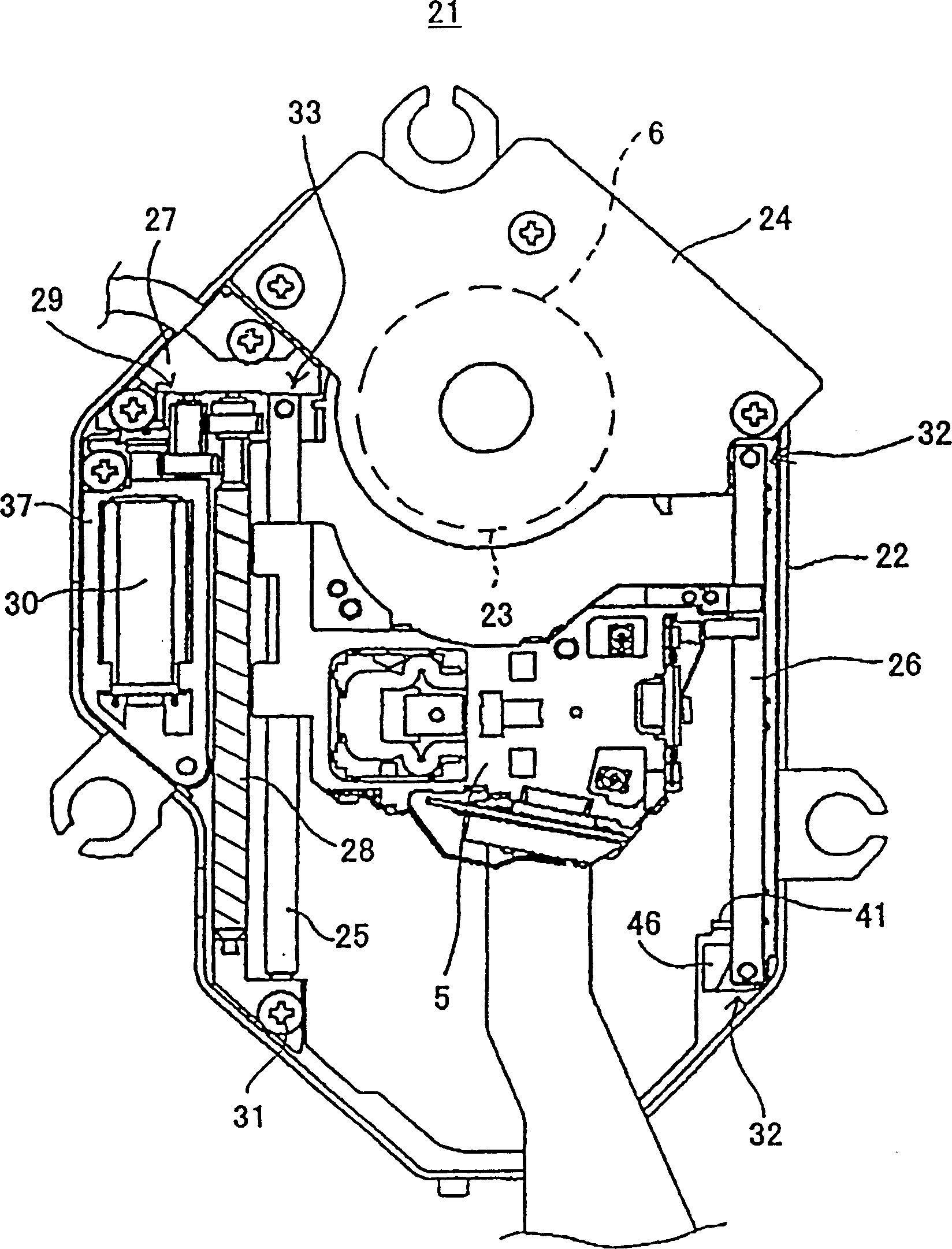

[0052] Please refer to the following figures to illustrate the embodiments of the present invention.

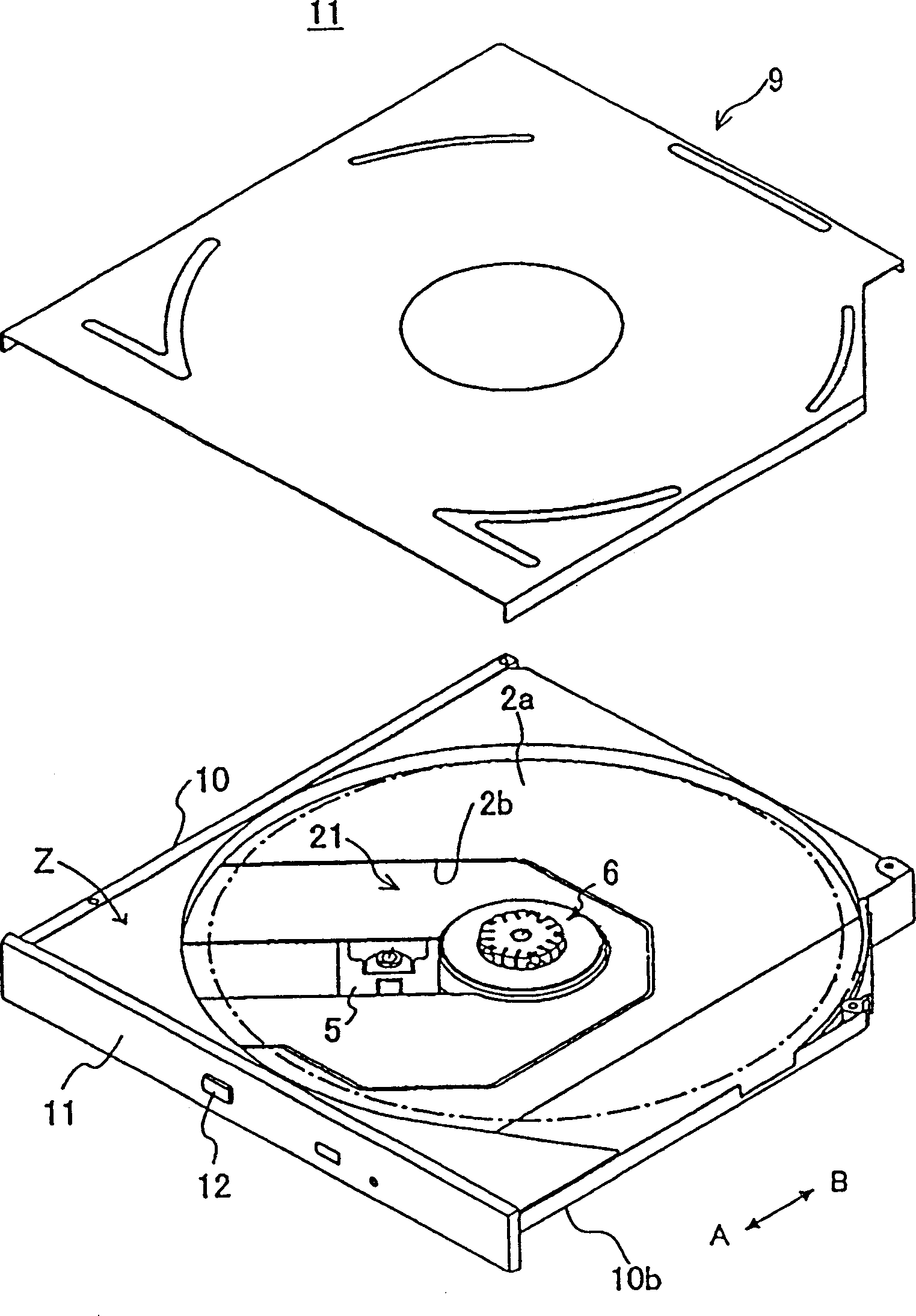

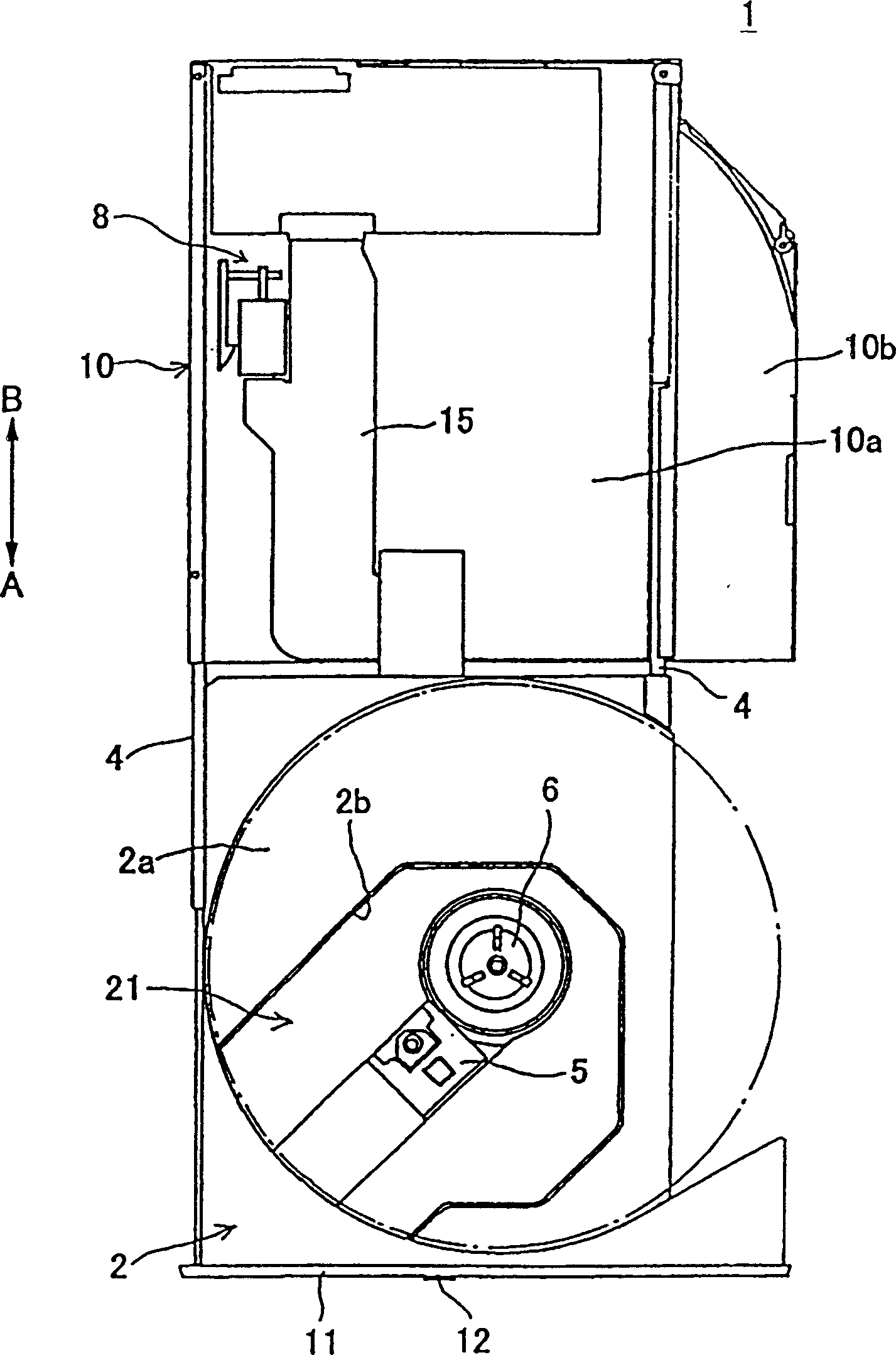

[0053] figure 1 It is a perspective view of a CD-ROM drive device according to an embodiment of a recording and reproducing device of the present invention. figure 2 It is a plan view of the disk unit with the tray pulled out.

[0054] Such as figure 1 and figure 2 As shown, a CD-ROM drive device 1 (hereinafter referred to as "device") as a recording and reproducing device is a built-in device built in a casing of a notebook computer (not shown).

[0055] This device 1 is approximately composed of: facing the disc (such as figure 1 The tray 2 put in, the slide mechanism 4 supporting the tray 2 slidably, the optical head 5 arranged on the tray 2, rotating and driving the loaded disc (CD- ROM) turntable 6, when the tray 2 moves to the loading position, the locking mechanism 8 that locks the tray 2 (lock) constitutes.

[0056] figure 1 In order to remove the top plate 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com