Waste gas treating device and method in dust removing room device

A technology for processing equipment and waste air, applied in mechanical equipment, separation methods, lighting and heating equipment, etc., can solve problems such as cost, and achieve the effect of saving costs and reducing the amount of fresh air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

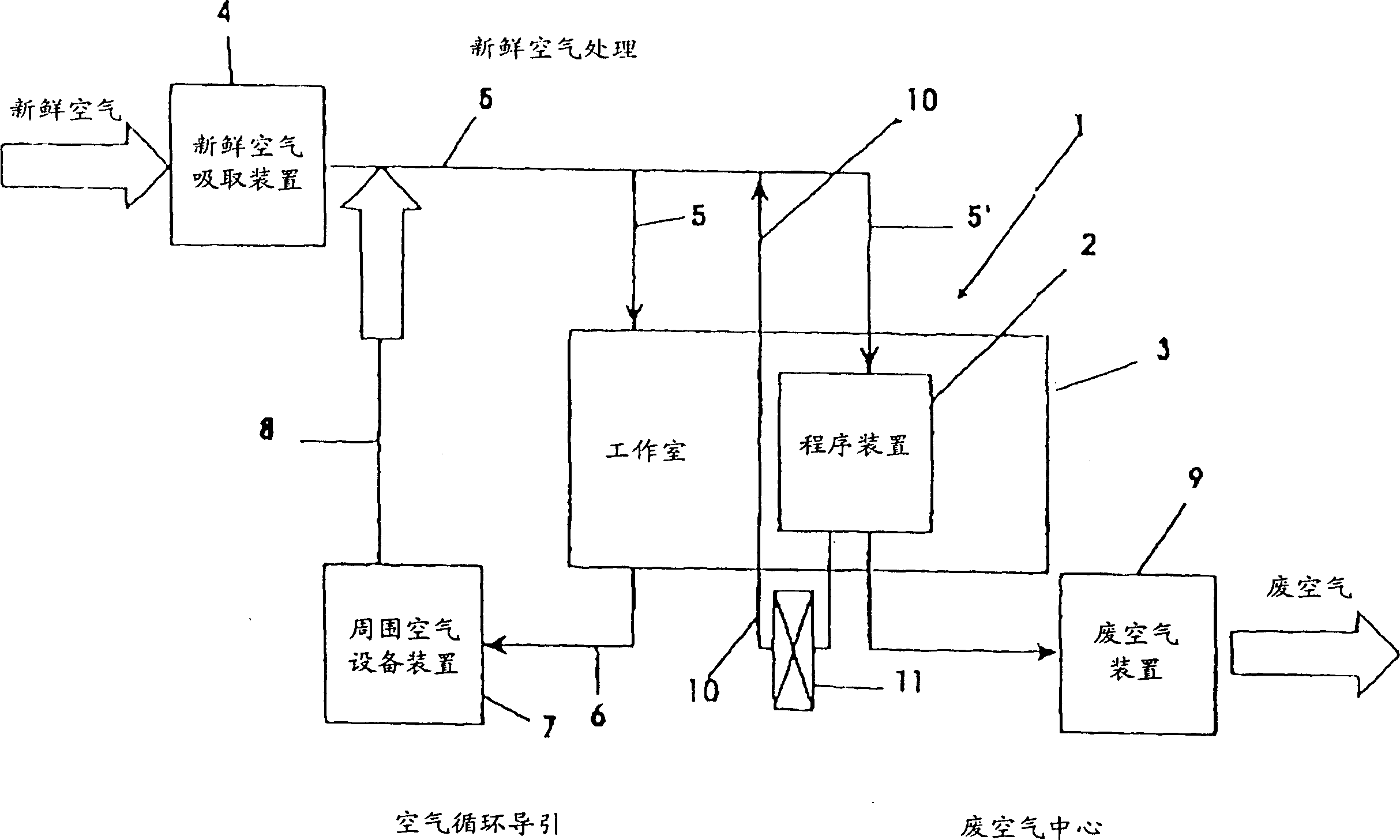

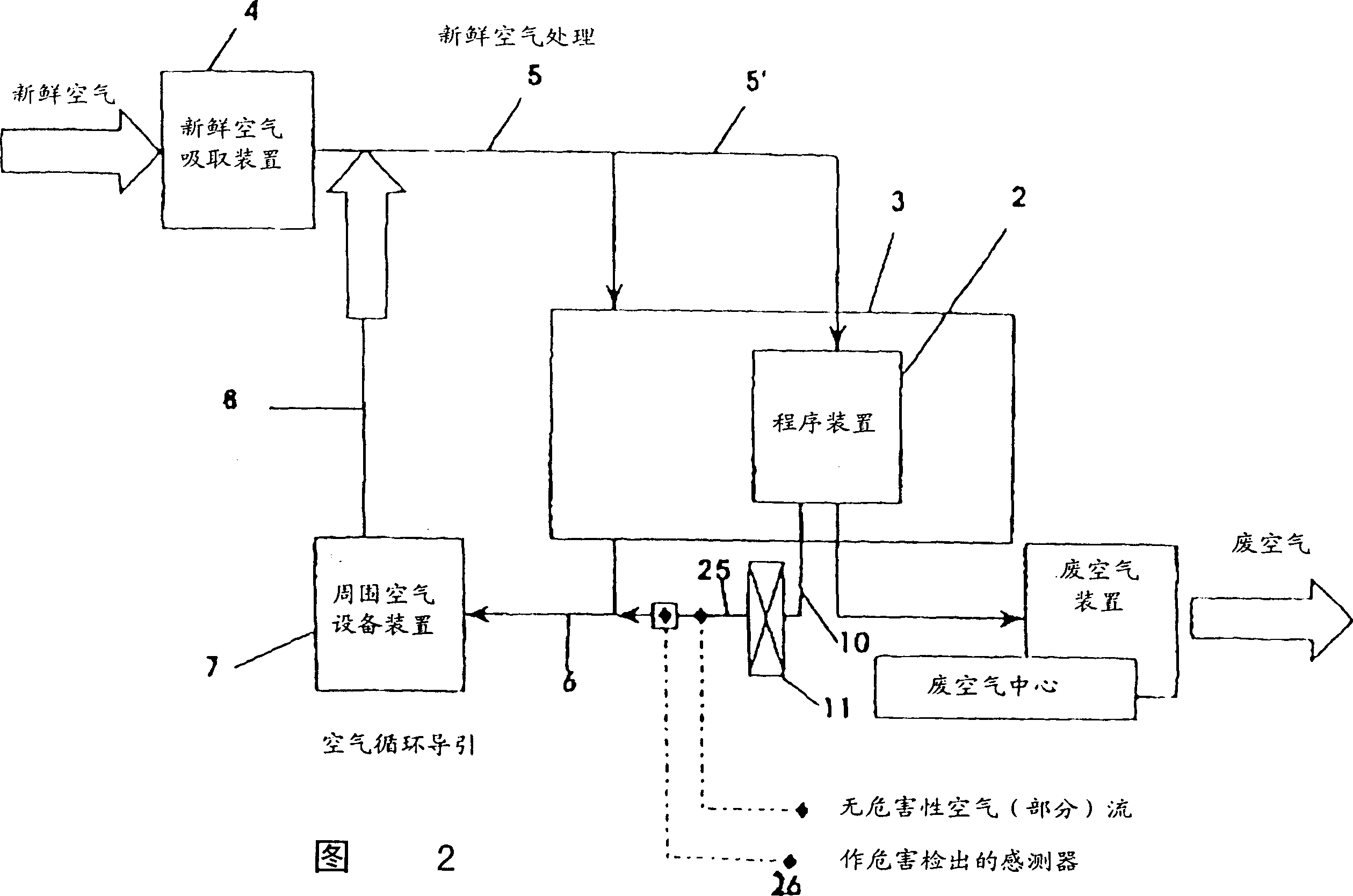

[0013] figure 1 The apparatus shown in is used to treat exhaust air from process plants 2 such as plants for wet etching, cleaning, chemical-mechanical polishing and electroplating plants used in semiconductor manufacturing. The device 1 may have only one program device 2, such as figure 1 As shown, or there may be several sequencers 2. The sequencer 2 is accommodated in a working chamber 3 , which is supplied with fresh air via at least one line 5 via a fresh air suction device 4 . The procedure device 2 also supplies the fresh space via a branch pipeline 5', and fresh air can also indirectly supply the procedure device 2 via the working chamber 3. This branch pipeline 5 ' just does not need like this. The fresh air should flow through the studio 3 from top to bottom in a laminar flow manner. The waste air leaving the working chamber 3 is separated via at least one line 6 to an ambient (circulation) air plant device 7 which sends the waste air back to the supply air line ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap