Waveguide display

A display and waveguide technology, which is applied in the field of manufacturing flat panel displays, can solve the problems of easy blocking of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

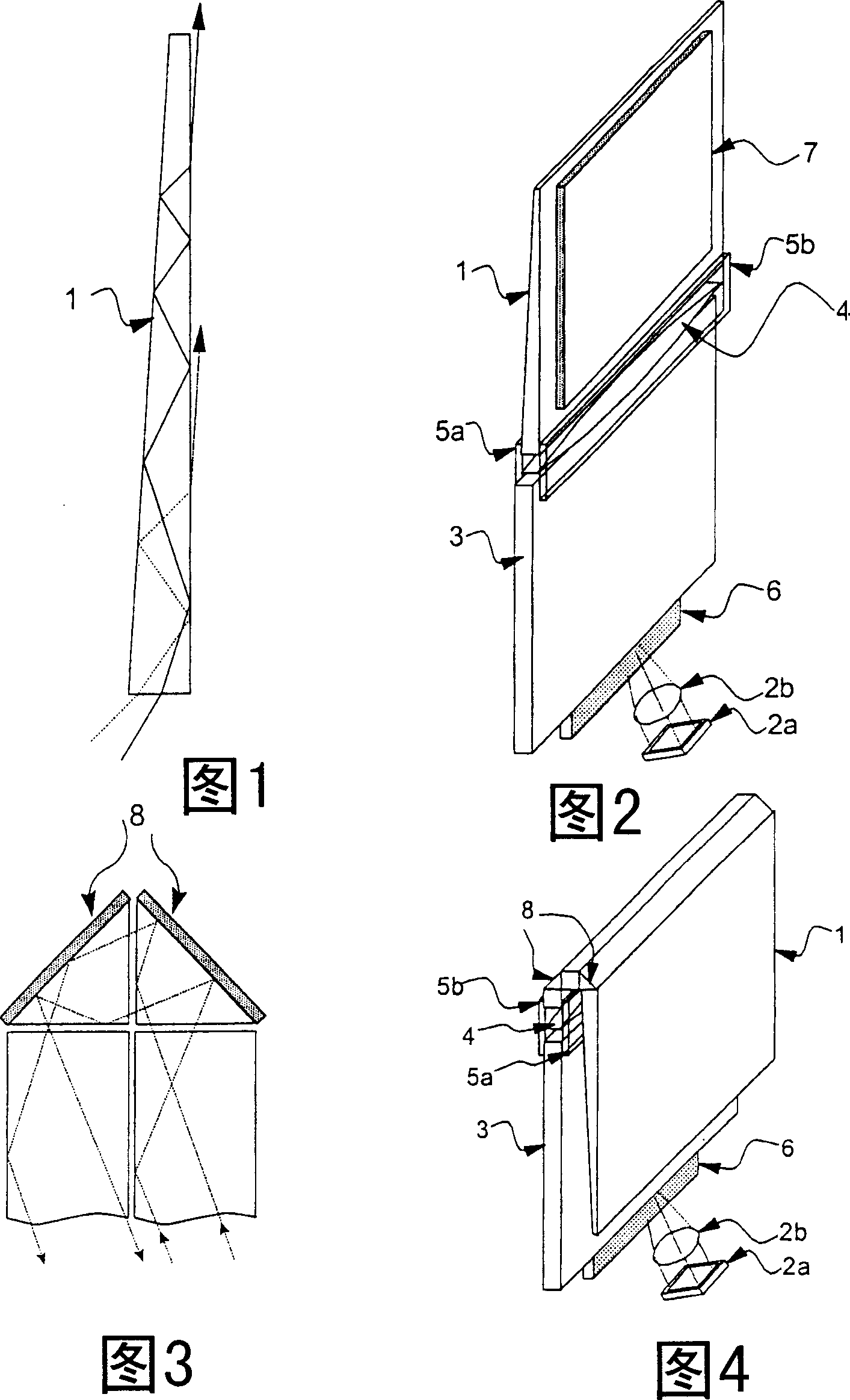

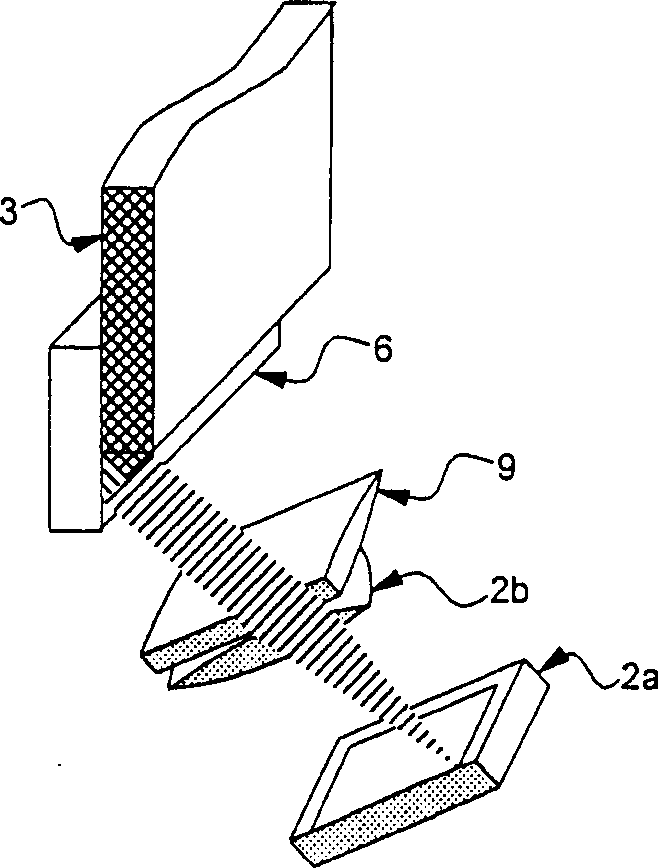

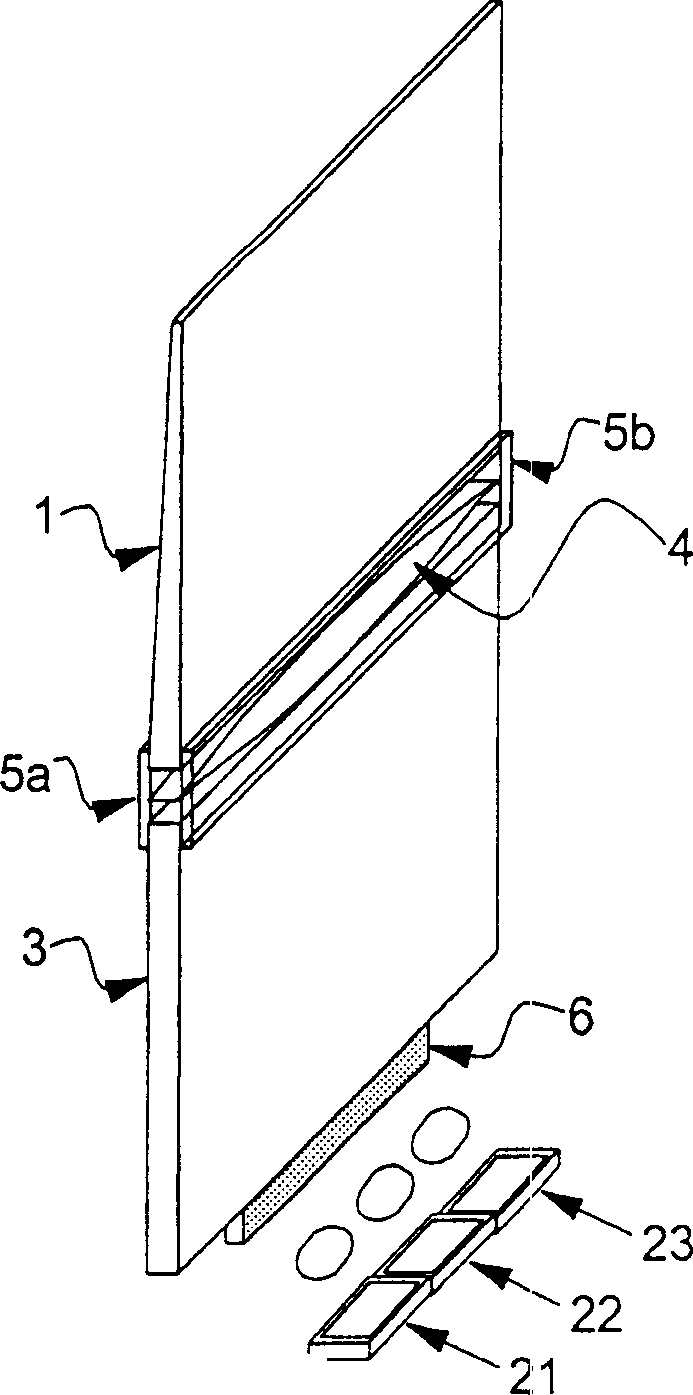

[0026] It is well known that a ray striking a cuboid plate made of transparent material at a sufficiently small out of plane angle will be reflected back and forth at the sides of the cuboid by total internal reflection until the ray reaches the opposite end from which it was incident . The ray is said to be guided, the slab of material is called the waveguide, and the out-of-plane angle of the ray remains constant as it propagates through the waveguide.

[0027] But if a ray is injected into the thick end of a tapered waveguide as shown in Figure 1, the out-of-plane angle measured with respect to taper 1 will change when the ray is reflected at the opposite face of the taper. Eventually the ray travels far enough along cone 1 that the out-of-plane angle becomes greater than the critical angle, at which point the ray exits cone 1. Therefore, the distance that light enters into the tapered waveguide 1 and leaves the cone 1 is determined by the incident angle of the light, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com