Virtual measuring method for determining characteristic curve of air duct for electronic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific implementation steps and implementation results of an embodiment in the CFD simulation software Flotherm3.1. In order to facilitate the reference comparison of implementation in the simulation software, the original expressions of some concepts in the simulation software are listed in parentheses.

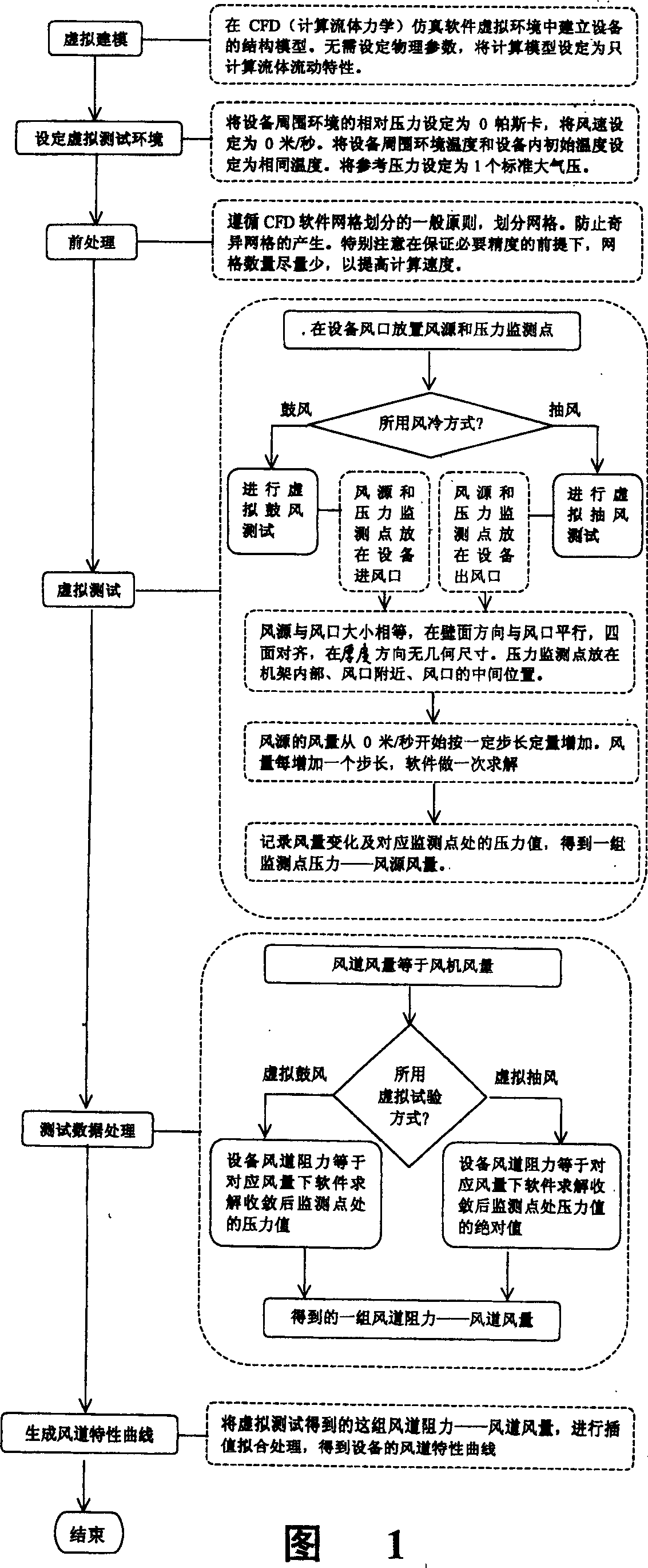

[0030] The flow chart of the implementation of the present invention is shown in Figure 1:

[0031] 1) Virtual modeling

[0032] Build the structure model of the equipment in the virtual environment of CFD (computational fluid dynamics) simulation software. Including the equipment rack and the geometric model, position and assembly relationship of each component in the rack.

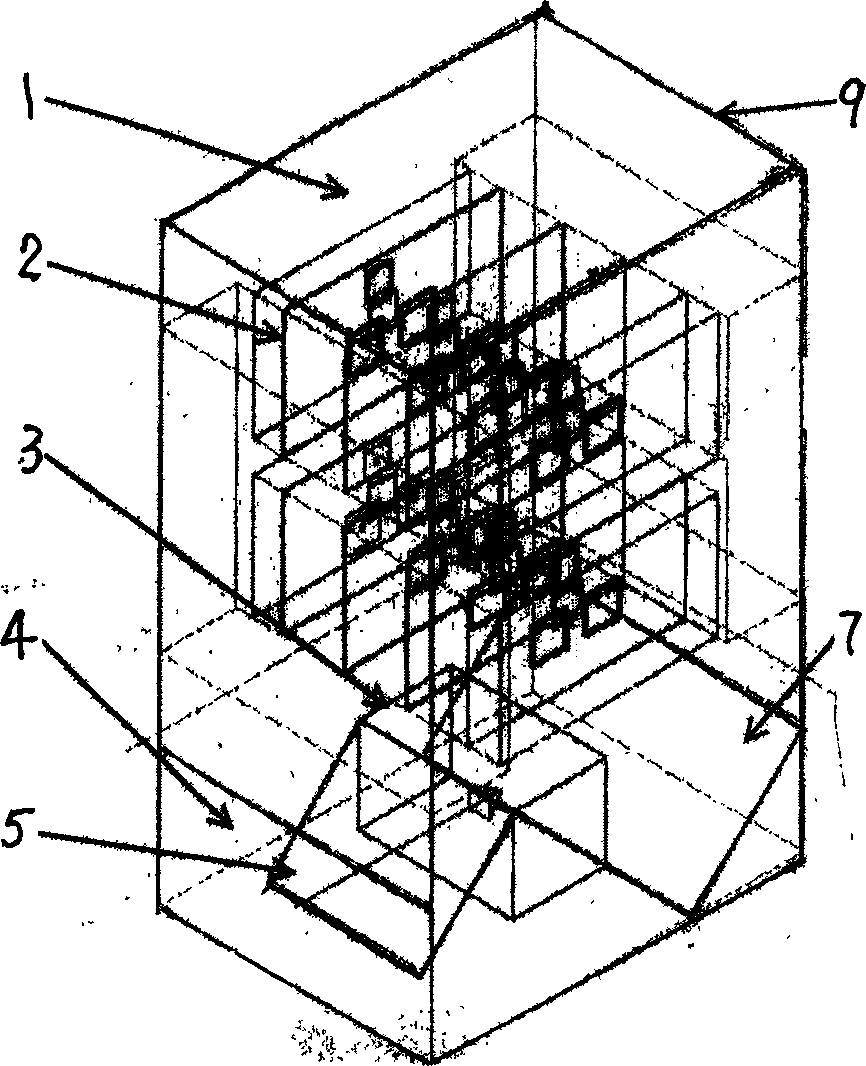

[0033] Establish the structure model of the device in the virtual environment provided by Flotherm3.1 such as figure 2 Shown. The air outlet 1 is at the top of the rack 9 and the air inlet 4 is at the bottom of the front of the rack 9. Adopt the bottom air inlet and the top air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com