Automatic counting bar material systems

An automatic counting and bar material technology, which is applied in counting objects, counting mechanisms/items, counting of items shipped through conveying devices, etc., to achieve fast response, solve accurate counting problems, and meet real-time counting requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

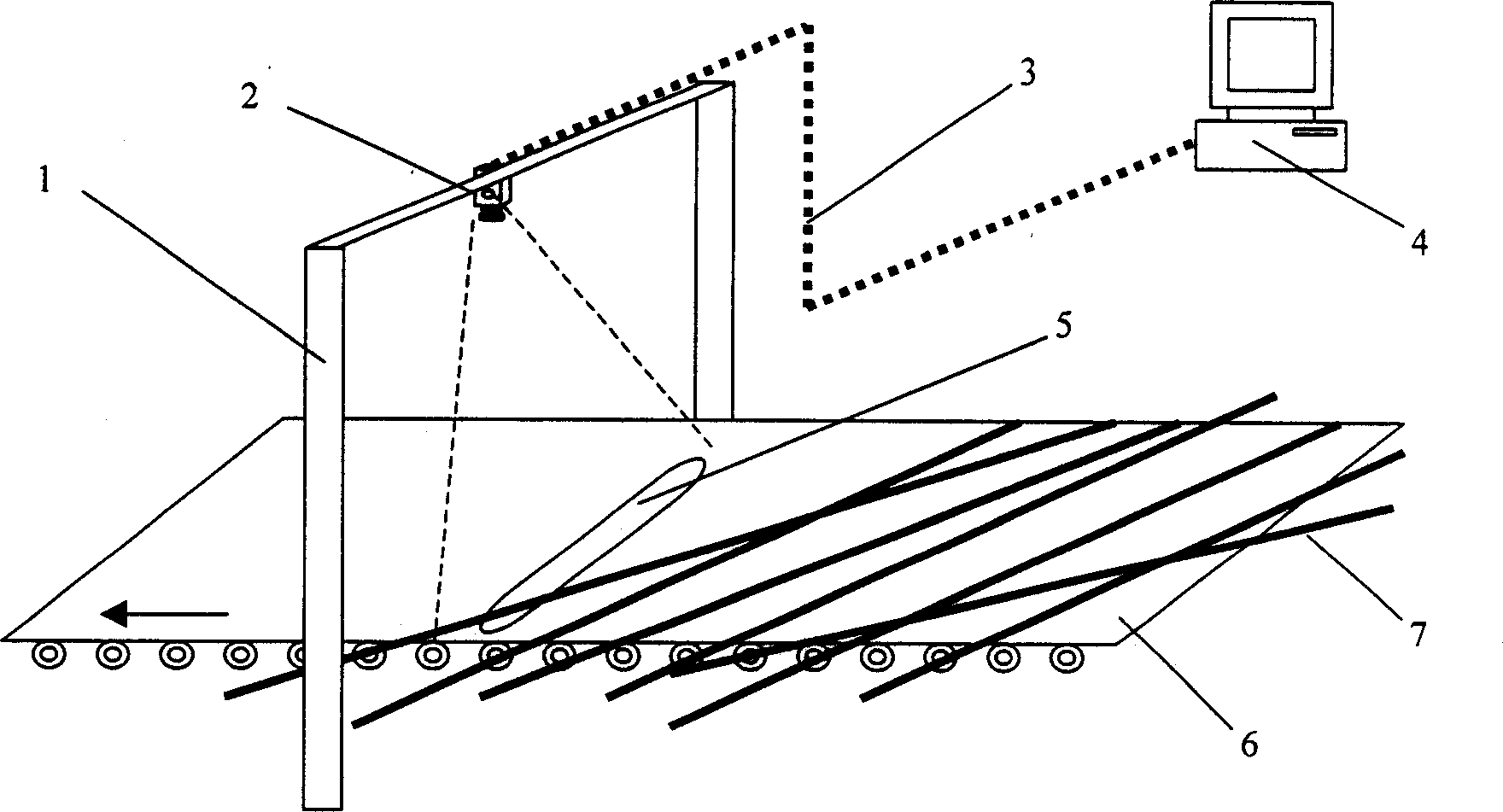

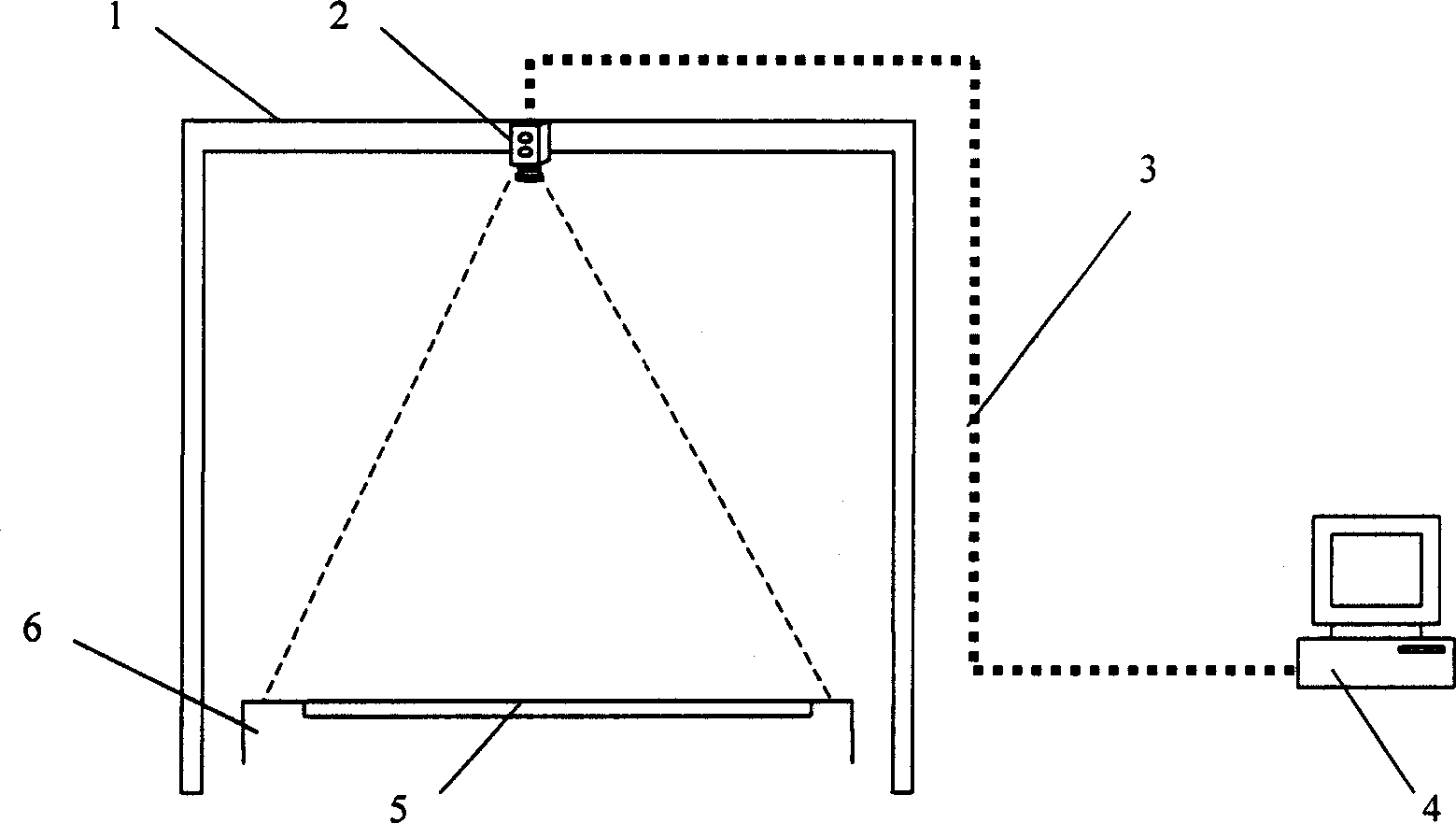

[0018] Install the system according to Figure 1 and Figure 2. First, install a stable support frame 1 across the conveyor chain 6, install a linear array CCD camera 2 on the support frame 1, install a fluorescent tube 5 at the bottom of the conveyor chain 6, and adjust the position and angle of the camera 2 so that the camera 2 and the light Tubes 5 are in the same vertical plane. The video camera is connected with the computer 4 through the data line and the control line 3 .

[0019] After the system is installed, light the lamp tube 5, and turn on the camera 2, and observe the images collected by the camera 2 through the computer 4. Adjust the position and angle of the camera 2 to ensure that the camera 2 can completely capture the light emitted by the lamp tube 5 .

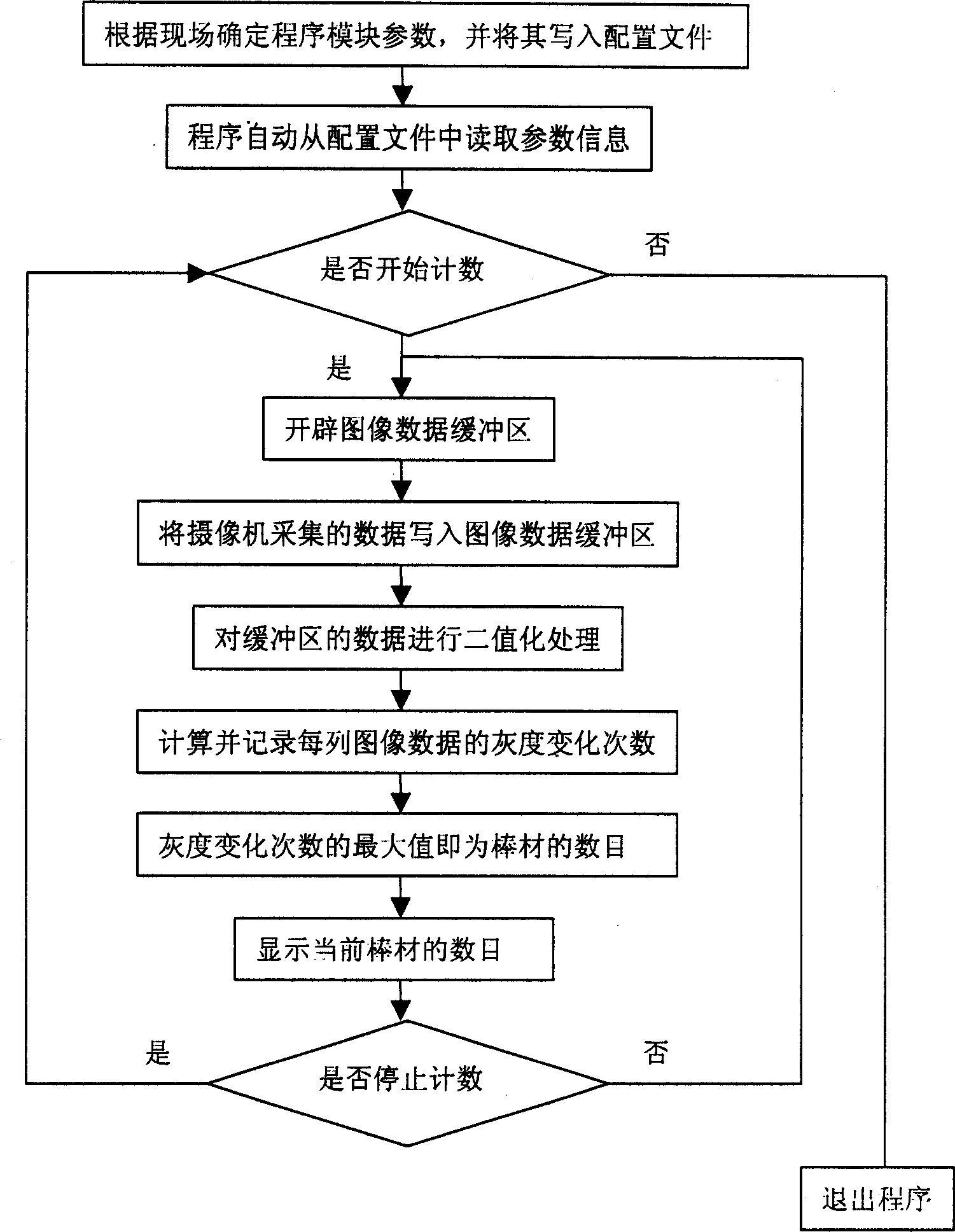

[0020] System software according to Figure three The flow chart design, the software consists of three main parts:

[0021] 1. Create an image data buffer to store the image data collected from the camera. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com