Weighing and counting method and device

A technology of weighing counting and weighing instruments, which is applied in the direction of measuring devices, weighing, instruments, etc., can solve the problems of damaged conveyor chains, unsuitable and unsuitable products scattered irregularly or piled up on each other, so as to achieve the goal of not affecting continuous operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: a kind of weighing and counting method, it uses weighing platform 4 and weighing instrument to form weighing equipment, and weighing instrument selects the SCW-PLC200 type weighing controller produced by Shanxi Dongtaike Instrument Co., Ltd., and is arranged on The stacking mechanism between the continuously running production conveyor belt 1 and the weighing platform 4. The weighing platform 4 is composed of a material receiving platform (or material receiving frame) and a load cell rigidly connected to it. The stacking mechanism is electrically connected to the weighing instrument. Contains the following steps:

[0038] (1) Set parameters on the weighing instrument:

[0039] Set the target weight m of a single product; according to the deviation rate a of the single product weight on the production conveyor belt to the target weight m of a single product, calculate the upper limit SM of the small pile weighing counting error SM of the number of products ...

Embodiment 2

[0047] Embodiment 2: A weighing and counting method, the same as Embodiment 1 will not be repeated, the difference is that: step 1 also includes, according to the average flow V (pieces / second) and peak value of standard products on the production conveyor belt The flow rate Vp (pcs / s) and peak time tp (s) determine the receiving time t (s) for continuously collecting a small pile of products, t=SM / V+(1-Vp / V)*tp.

Embodiment 3

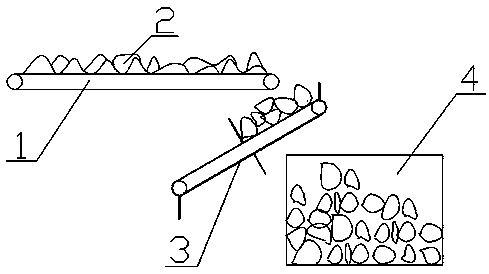

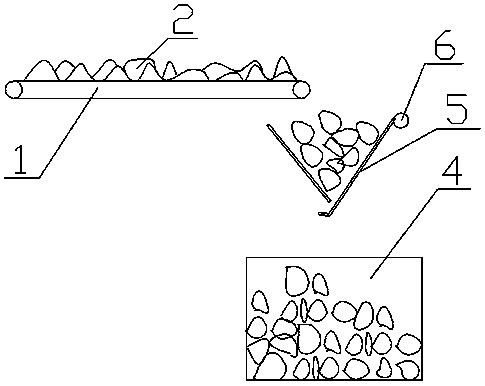

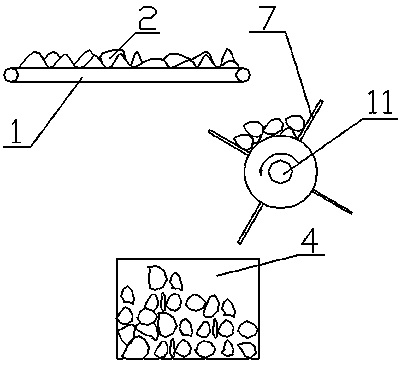

[0048] Embodiment 3: as figure 1 Shown, a kind of weighing and counting device, it comprises sub-pile mechanism and weighing platform 4 and weighing instrument, sub-pile mechanism and weighing platform 4 are all electrically connected with weighing instrument, and weighing platform 4 and weighing instrument form weighing equipment , the weighing instrument selects the SCW-PLC200 weighing controller produced by Shandong Dongtaike Instrument Co., Ltd., and the stacking mechanism is set between the continuously running production conveyor belt 1 and the weighing platform 4, and the random spacing is scattered or accumulated on the continuous The standard products 2 on the moving production conveyor belt 1 are collected into a small pile according to the time period of the receiving time t and then moved to the weighing platform 4 at one time. The stacking mechanism is a belt conveyor 3. The outer surface of the belt of the belt conveyor 3 is provided with an equal partition plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com