Novel fluidized bed biofilm carrier

A biofilm carrier, fluidized bed technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

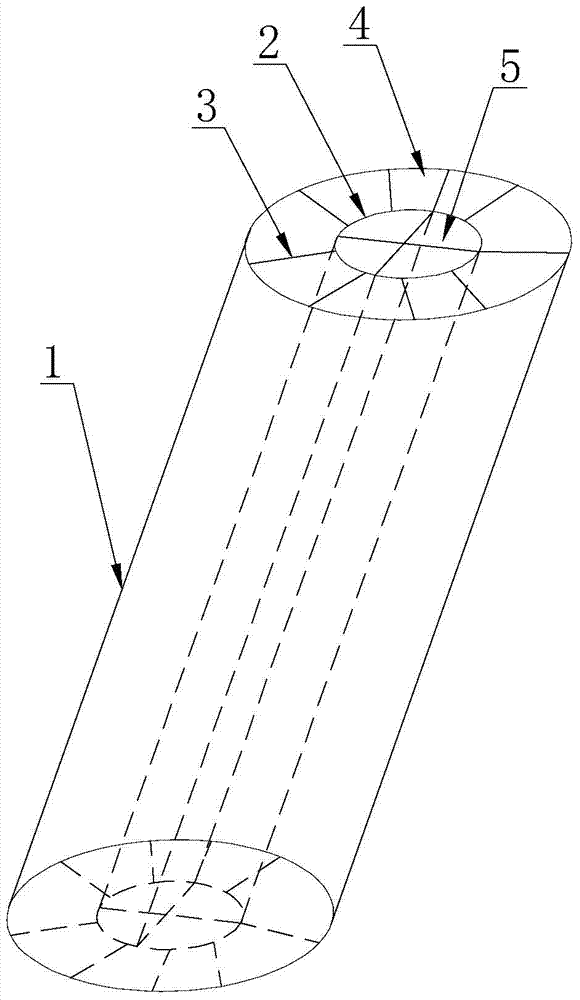

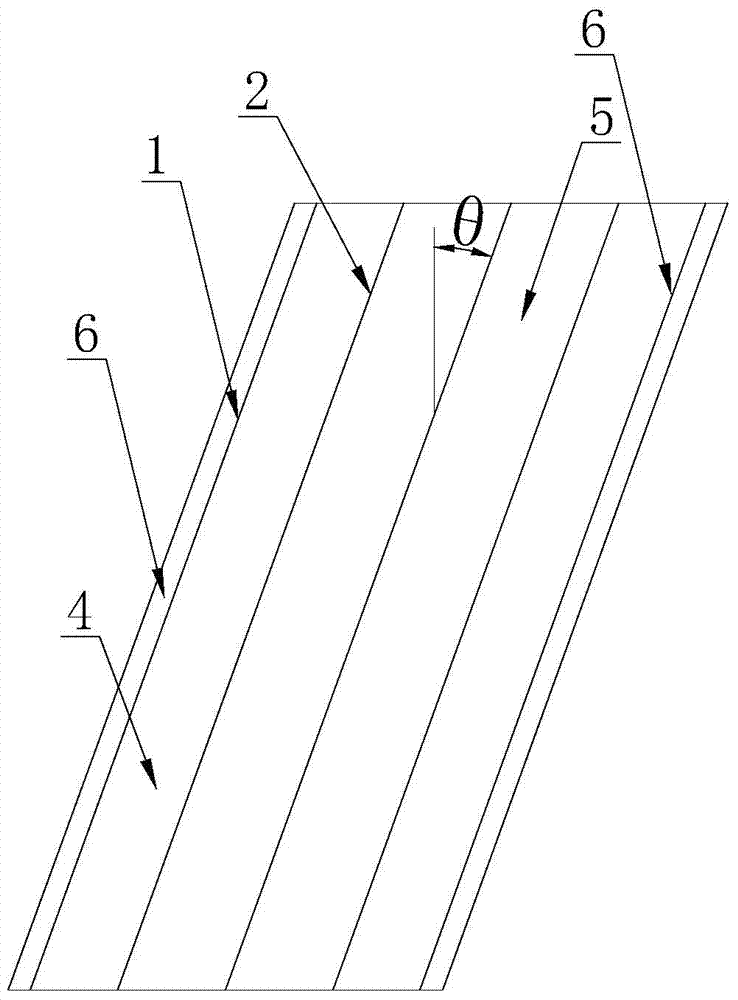

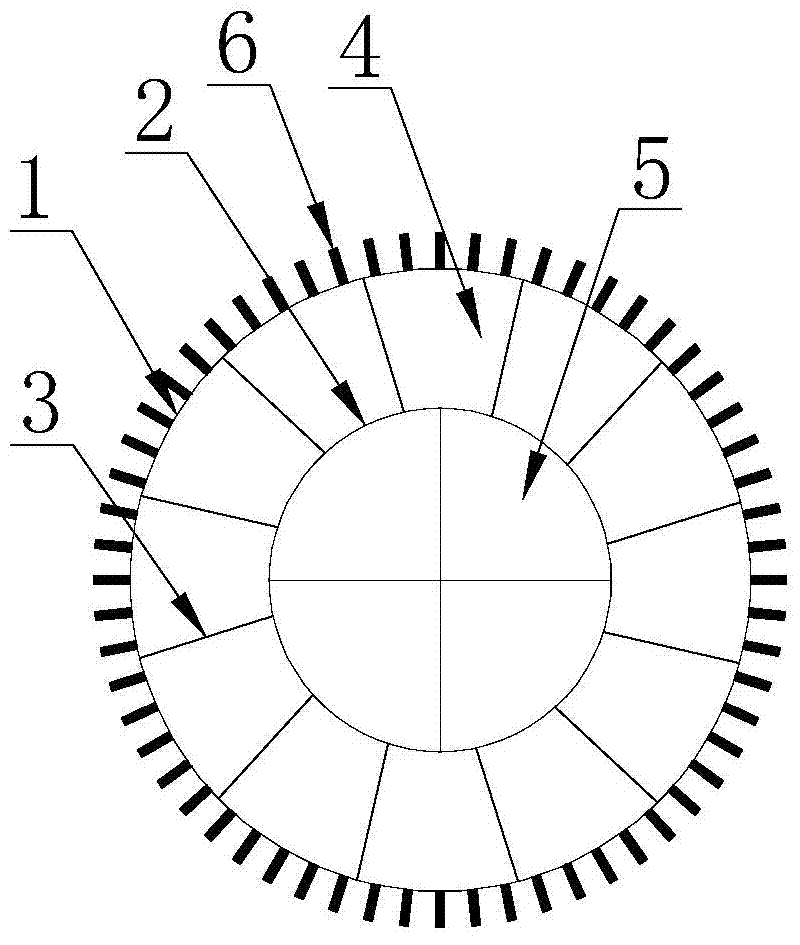

[0025] figure 1 It is a schematic diagram of the three-dimensional structure of the present invention, figure 2 It is a schematic diagram of a longitudinal cross-sectional structure of the present invention, image 3 It is a schematic diagram of the cross-sectional structure of the present invention, such as figure 1 , figure 2 , image 3 As shown in , a novel fluidized bed biofilm carrier of the present invention includes a hollow cylinder 1 with an inclined design, and the longitudinal inclination angle θ of the hollow cylinder 1 is 10°-30°, and θ in this embodiment is 15°. There is a coaxial annular cylinder 2 inside the hollow cylinder 1, and the hollow cylinder 1 and the annular cylinder 2 are connected by a rib wall 3, and the rib walls 3 are uniformly distributed in a circular array around the center of the hollow cylinder 1, and adjacent The rib wall 3 surrounds the hollow cylinder 1 and the annular cylinder 2 to form a cell 4 . There is a compartment 5 formed ...

Embodiment 2

[0030] The present invention provides another specific embodiment, Figure 4 It is a schematic diagram of the three-dimensional structure of another embodiment of the present invention; Figure 5 for Figure 4 Schematic diagram of the transverse cross-sectional structure. The specific plan is: a new type of fluidized bed biofilm carrier, including a hollow cylinder 1 with an inclined design, the vertical inclination angle θ of the hollow cylinder 1 is 10°-30°, and in this embodiment θ is 10°, the hollow cylinder 1. The interior is divided into honeycomb cells 7, and the outer peripheral surface of the hollow cylinder is provided with serrations 6.

[0031] Wherein, the honeycomb cell 7 can also be designed as an irregular radial honeycomb structure, which will not be described in detail in the drawings in this embodiment.

[0032] In this embodiment, the external cut surface has a radial zigzag structure. Under the same load conditions, the three-phase mass transfer effect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com