Self-cleaning material splitting box of wood flour fuel boiler

A self-cleaning and fuel technology, applied in solid fuel pretreatment, block/powder fuel preparation, fuel supply, etc., can solve the problems of equipment can not run continuously, the distribution box can not be seen, wood chips stay and accumulate, etc. Simple structure, low cost and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

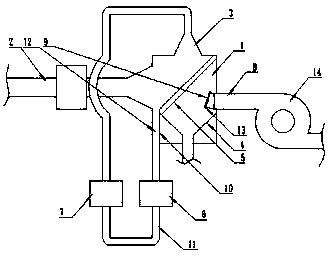

[0016] Such as figure 1 The shown self-cleaning distribution box of a wood powder fuel boiler includes a box body 1 whose left side wall is connected to the dust collection main pipe 2. The box body 1 is provided with a front that is inclined at 45°~60° and faces the dust collection main pipe. 2 screen 5, the lower end of the screen 5 is connected with a partition 10, and there is a gap between the partition 10 and the inner wall of the box 1 below the dust collection main pipe 2 as a wood chip passage 12, and the wood chip passage 12 passes through The pipeline 11 of the pulverizer 6 and the elevator 7 is arranged in turn to communicate with the material return port 3 on the top of the box body 1, and the bottom of the box body 1 below the screen 5 is provided with a discharge hopper 4, and the right side wall of the box body 1 is A blowpipe 8 connected to the air outlet of the blower 14 is provided, and the mouth of the blowpipe 8 is inclined upward by 30°~45° toward the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com