Industrial pulverized coal boiler with double horizontal hearths arranged oppositely

A pulverized coal boiler, dual-level technology, which is applied to the combustion of multiple fuels, burners of powder fuels, combustion of lump fuels and liquid fuels, etc. problem, to achieve the effect of accelerating the cooling of the out-of-service furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

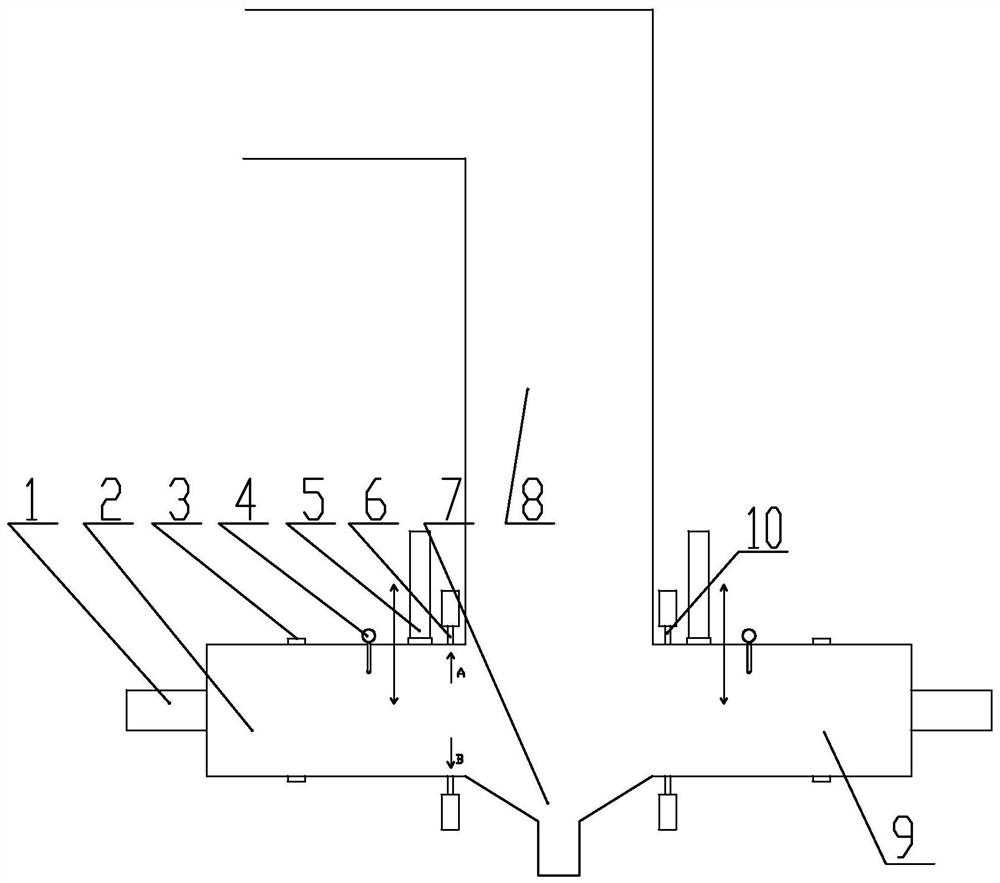

[0032] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, an industrial pulverized coal boiler with dual horizontal furnaces facing each other in this embodiment includes a burner 1, a No. 1 horizontal furnace 2, a flue gas baffle 5, a No. 1 flue gas recirculation tube bundle 6, a rising Furnace 8, No. 2 horizontal furnace 9, No. 2 flue gas recirculation tube bundle 10 and steam-water circulation unit;

[0033] One side of the rising furnace 8 is provided with a No. 1 horizontal furnace 2, and the other side of the rising furnace 8 is provided with a No. 2 horizontal furnace 9. Both the No. 1 horizontal furnace 2 and the No. 2 horizontal furnace 9 are connected to the rising furnace 8. Furnace 2 and No. 2 horizontal furnace 9 are arranged opposite to the ascending furnace 8, and the joints of No. 1 horizontal furnace 2 and No. 2 horizontal furnace 9 and ascending furnace 8 are provided with flue gas baffles 5, and the flue gas baff...

specific Embodiment approach 2

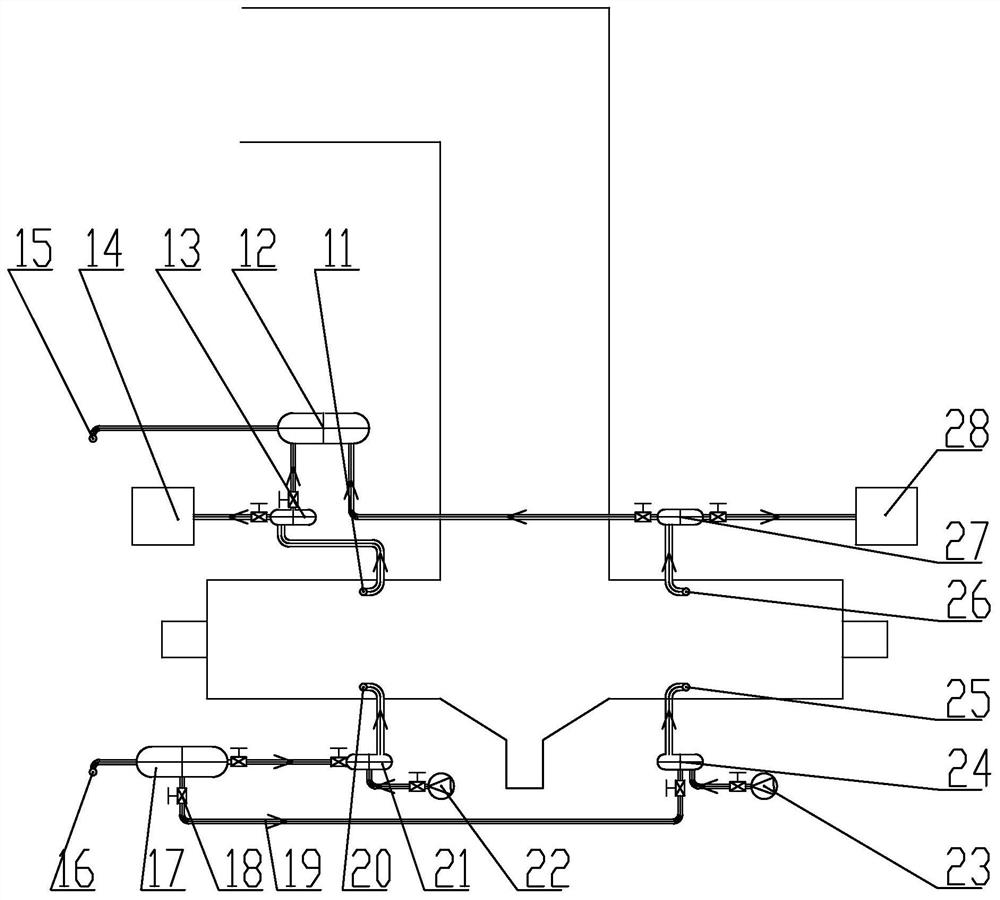

[0035] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment. This embodiment is a further limitation on the industrial pulverized coal boiler described in the first specific embodiment. An industrial pulverized coal boiler with a double-level furnace opposed arrangement described in this embodiment. The steam-water cycle The unit includes No. 1 water wall outlet pipe 11, upper header 12, No. 1 upper grading header 13, No. 1 cooling water tank 14, upper header outlet pipe 15, lower header inlet pipe 16, lower header 17, and connecting branch pipe 19 , No. 1 water wall inlet pipe 20, No. 1 lower stage header 21, No. 1 cooling water pump 22, No. 2 cooling water pump 23, No. 2 lower stage header 24, No. 2 water wall inlet pipe 25, No. 2 water cooling Wall outlet pipe 26, No. 2 upper grading header 27 and No. 2 cooling water tank 28;

[0036] The upper part of the No. 1 horizontal furnace 2 is connected to the input port at the bottom of t...

specific Embodiment approach 3

[0040] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment. This embodiment is a further limitation of the industrial pulverized coal boiler described in the second specific embodiment. An industrial pulverized coal boiler with a double-level furnace opposed arrangement described in this embodiment. The steam-water cycle Each pipeline in the unit is provided with a valve 18;

[0041] In this specific embodiment, a valve 18 is arranged on each pipeline in the steam-water circulation unit to facilitate the control of the steam-water circulation unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com